A well known research institute in East Asia develops large-scale aspheric optical

mirrors and lenses for space applications. The mirrors, manufactured with a high

surface quality of λ/30 rms and a diameter up to 2 m, are used in high resolution

satellites or large telescopes. In the testing process of the space optics, a Newport

HXP series Hexapod 6-axis parallel kinematic motion positioner plays an important

role for metrology and quality control.

Due to a high cost of launching pay loads into space, researchers have discovered

ways to reduce size and minimize weight of optical systems used in the satellite. To

produce a smaller overall packaging that is lighter and more cost-effective, a single

large high precision aspheric lens or mirror has replaced multi-lens array that is

more complex in design. As image quality is a key element of the optical system,

surface quality of this monolithic aspheric lens or mirror is fully characterized after

fabrication in order to avoid possible deterioration of overall imaging in satellite

CCD camera.

In the test set-up, a small reflective mirror or a lens, which represents a CCD camera

inside the satellite, is mounted on a motorized platform for measurements of

Modulation Transfer Function (MTF) and Wave front Distortion Error (WDE) of the

device under test (DUT), which is the large aspheric lens or mirror placed in the

beam path. When a collimated beam passes through or gets reflected from the

DUT, the change in shape of a wave front is observed and compared to the incident

wave front, providing an indication of the optical surface quality. As the DUT comes

in various sizes and requires testing under varying incident beam angles, the

controlling optics need five distinct freedoms of motion: two for positioning to the

center of incident beam, two for tip-tilt adjustment and one for focusing along the

optical axis.

As it became evident that alignment is the most labor-intensive and time-consuming

part of testing process, researchers approached Newport for a Hexapod solution as

an alternative to their existing setup using motorized linear and rotary stages in a

Space Optics Testing and Metrology with Newport Hexapod combined stack. With the stacked stages, it took several days to reconfigure the setup for a new DUT, mainly because it was difficult to relocate the pivot point of the optics following any change in height of optical axis or focal distance of the mirror or the lens. Moreover, due to an error contributed from each axis movement in the stack, it was not easy to estimate the travel lengths required in all axes to reach a desired position in 3-D coordinate within a tight tolerance.

Thanks to dual coordinate systems provided by the Hexapod control algorithm and

its ability to define virtual pivot points, overall production cycle times are greatly

reduced, minimizing the cost of operation.

“It took almost one week for an optical system qualification and characterization

process before arrival of the Newport hexapod. Now, it takes no more than two

days for us to complete the test cycle”, a researcher says.

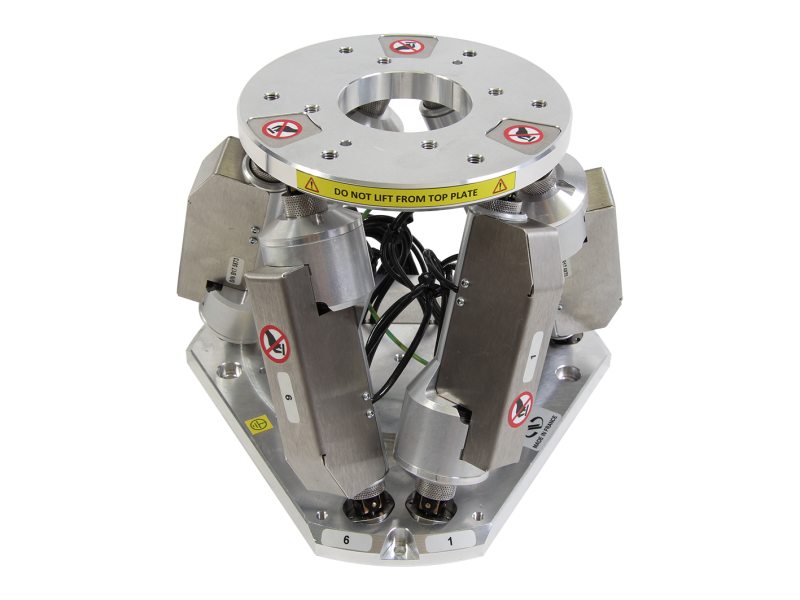

The Newport HXP100 series Hexapod, driven with six high performance DC servo

motor LTA actuators, provides six degrees of freedom that are X, Y, Z, pitch, roll and

yaw. A virtual pivot point allows the user to freely choose the rotation center and it

helps minimize the time to reconfigure the setup, following any shift in the position

of optical components or beam orientation. The HXP100 provides an option to

relocate the entire coordinate system so that a single user-defined coordinate

system can be used to control all the active components including laser beam, DUT

and reference optics. A dedicated Hexapod controller HXP100-ELEC provides a high

speed Ethernet TCP/IP communication interface, advanced motion profiler with

synchronized control and various software program libraries including LabVIEW to

help ensure a smooth programming for integrated software control in user

environments.

APPLICATION NOTE :-

Travel range (X) ±29 mm

Travel range (Y) ±26 mm

Travel range (Z) 28 mm

Travel range (Θx) ±12°

Travel range (Θy) ±10°

Travel range (Θz) ±20°

Min. incremental motion (X, Y, Z) 0.5 μm

Min. incremental motion (Θx, Θy, Θz) 5 μrad

Repeatability (X, Y, Z) 0.5 μm

Repeatability (Θx, Θy, Θz) 17 μrad

Max. speed (X, Y, Z) 1 mm/s

Centered load capacity 200 N

Rigidity (Z) 40 N/μm

For additional information, please contact Newport applications and sales engineers at tech@newport.com.