Panelfisa trusts in production metrology to optimize time and improve the quality of its fastening elements.

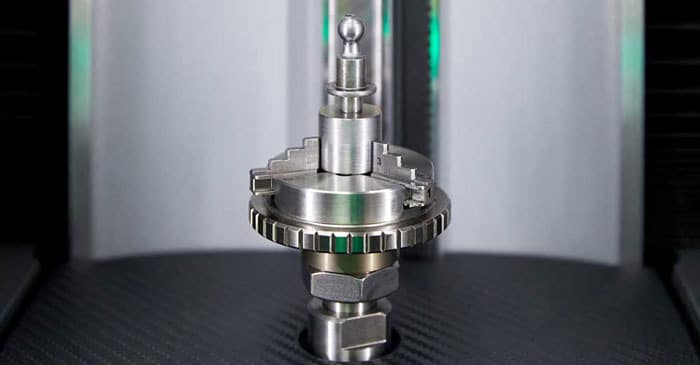

Technology: Vici Vision Techno

Sector: Automotive

See Vici Vision Techno product – https://www.sariki.es/en/production-metrology/solutions/in-line-optical-measurement/vicivision-techno-series/

Panelfisa S. Coop, founded in 1989, is a global supplier of fastening elements produced by cold stamping. They are specialized in the automotive sector and have a large international presence (70% of their production is exported to more than 20 countries).

Their headquarters are located in Tolosa (Gipuzkoa) and they are committed to innovation to grow together with their customers.

In 2015 Panelfisa acquires a Vici Vision MTL1 machine to reduce measurement times and make the controls more reliable by automating the measurements that were previously carried out by hand in cold stamping (caliper, micrometers, etc.). Although the goal was to give direct support to production, initially the machine was installed in the quality lab and began to use it sporadically. Little by little they were overcoming the insecurities that people initially had with the new system.

They visited different companies around, where Vici Vision technology was giving direct support to production and being aware of the advantages it could mean for Panelfisa, they decided to launch a project led by Kepa Ezeiza and Aitor Loyarte with the aim of integrating the Vici Vision machine in workshop.

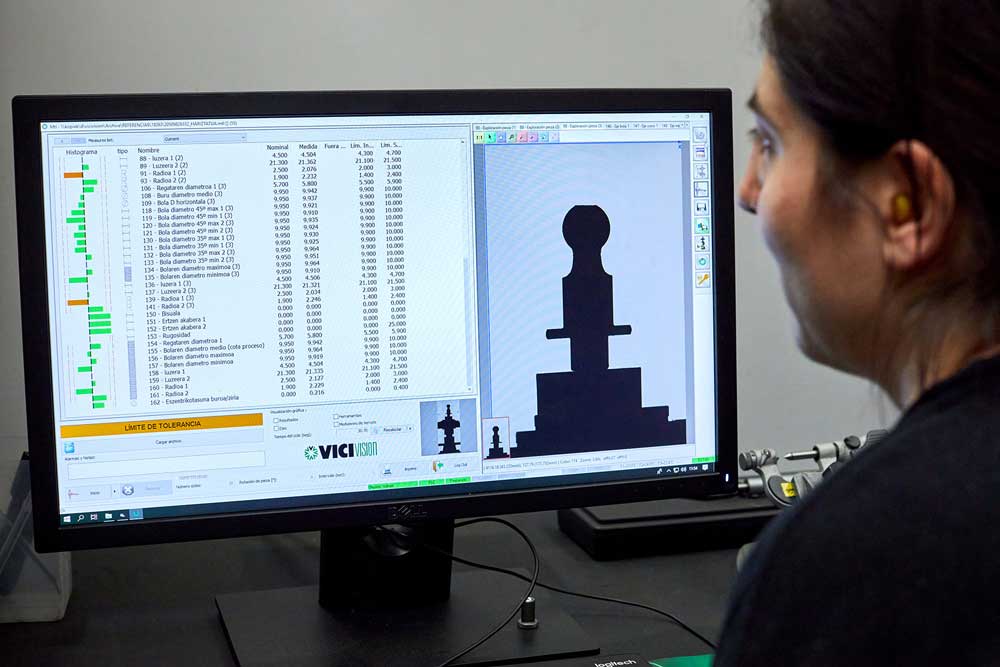

Thanks to the project, they obtain a great knowledge of the machine and adapt it to the stamping process. Sariki collaborates in the project offering knowledge and support in the testing and programming of parts. During the tests, Panelfisa develops a program together with Ibermática to dump the csv data from the Vici Vision to its production process control program. People began to see the advantages offered by the Vici Vision machine, the insecurities disappeared and decided to locate the Vici Vision in the production plant.

“Now we measure faster, with total reliability, we can give traceability to the measurements we have made, and we have accelerated the validation process of the parts. In addition, we have significantly improved the percentage of complaints, rejections and internal scrap.”

Aitor Loyarte

Process technician

Panelfisa S. Coop performs self-control depending on the frequencies defined together with the customer. In the production set-ups, the defined dimensions are controlled and then frequencies agreed with the customer are carried out. In this way they have production traceability from the beginning to the end.

In the plant of Tolosa (Gipuzkoa), they have different cold stamping machines, threading, laminating and machining machines. A total of 5 Vici Vision machines give support to production machines. They have reduced the measurement time of each part to approximately 50 seconds depending on the part; and achieve 100% traceability of the process, combining the information of the production orders and the measured data with the Vici Vision.

They have a central program to save only the measured dimensions. In this program appear all the machines of the workshop divided by equipment, so that anyone can use any machine of the workshop and perform the control of any type of part from any Vici Vision machine. In this way they solve any saturation problem they may have in the different sections.

Currently, Vici Vision technology is taken into account in all approvals from the beginning and they have a person responsible for preparing all stamping, laminating and threading programs. These programs are done offline, without the need to occupy a machine.

The next step in the project is the implementation of Vici Vision technology in the threading section and standardize the stamping and threading process in the Mexico plant.

“Vici Vision has meant a significant improvement in reducing measurement times, the quality of measurement and as a final result we transmit confidence to our customers.”