Solution enables identifying phases and analyzing texture in 3D.

ZEISS introduced ZEISS Mineralogic 3D software for automated quantitative mineralogy that achieves greater productivity and increased efficiency for the mining industry. By understanding composition, mineral relationships, and fabric of the geological materials under scrutiny, including locked grains, miners are able to respond faster to critical production questions.

Maximizing recovery requires improvements in efficiency

The process of crushing rock to separate valuable commodities uses a significant amount of energy, reportedly greater than 3% of the world’s total generated electric power. Increasing demand on resources leads to the evaluation of more complex, lower grade, ores. Maximizing recovery requires improvements in efficiency that involve detailed knowledge of the ore body and of the mineralogy that influences behavior during the beneficiation process. When time is of the essence, ZEISS Mineralogic 3D produces the actionable data needed for decision making, from comminution improvements, through process enhancements, to assessing the quality of the final concentrate.

Recognizing individual particles

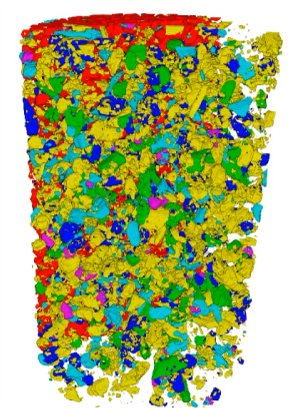

Built on the industry-leading ZEISS Xradia 3D X-ray microscope and microCT platforms using ZEISS DeepRecon Pro, ZEISS Mineralogic 3D software incorporates advanced and flexible machine learning protocols that recognize individual particles even when they are in contact with other particles. Particles are then automatically analyzed individually to provide a series of key outputs such as modal mineralogy, volume, porosity, feret dimensional measurements, associations, and liberation.

With ZEISS Mineralogic 3D, little to no sample preparation is required, stereological assumptions are eliminated as every grain is viewed in full in three dimensions, and time to actionable data is significantly reduced. Additionally, precious samples, i.e., meteorites and sample-return missions, are preserved due to the non-destructive nature of X-ray.

Allister McBride, Head of Materials Research Marketing at ZEISS Research Microscopy Solutions, says, “ZEISS Mineralogic 3D has the potential to be a game-changer for our customers, especially as requirements for new energy production and storage will ultimately require even higher yields from commodities. Greater efficiency and a faster time to results will be paramount. The intelligence built into these platforms enables the automation that has the potential to liberate individuals and organizations from arduous, time-consuming tasks, freeing them to be more strategic and productive. ZEISS Mineralogic 3D was developed by ZEISS Solutions Lab, and is a great example of our ability to rapidly respond to dynamic market requirements.”

James Strongman is Technical Director of Petrolab, Ltd., U.K., a service lab that has been providing geometallurgical results to the mining industry using ZEISS Mineralogic 2D since 2015. According to Strongman, “The arrival of a rapid scanning 3D system for mining and metallurgical applications opens the next chapter in process mineralogy. For our critical and precious metals projects, which are absolutely vital in the shift to low carbon, this will be a step change, as they are typically hosted in low grade ores. It has been notoriously difficult to get robust datasets from traditional techniques. ZEISS Mineralogic 3D is going to make those issues a thing of the past.”

ZEISS Mineralogic 3D is available for ZEISS Xradia Context microCT or Crystal CT and ZEISS Xradia Versa X-ray microscopes. It integrates ZEISS DeepRecon Pro for deep learning image processing, and ZEISS ZEN Intellesis for machine learning-assisted segmentation.

Also available is ZEISS Mineralogic 2D on ZEISS scanning electron microscope platforms and incorporating EDS detectors.

Press contact

ZEISS Research Microscopy Solutions

Vybhav Sinha

Phone: +49 3641 64-3949

Email: press.microscopy@zeiss.com

About ZEISS

ZEISS is an internationally leading technology enterprise operating in the fields of optics and optoelectronics. In the previous fiscal year, the ZEISS Group generated annual revenue totaling 6.3 billion euros in its four segments Semiconductor Manufacturing Technology, Industrial Quality & Research, Medical Technology and Consumer Markets (status: 30 September 2020).

For its customers, ZEISS develops, produces and distributes highly innovative solutions for industrial metrology and quality assurance, microscopy solutions for the life sciences and materials research, and medical technology solutions for diagnostics and treatment in ophthalmology and microsurgery. The name ZEISS is also synonymous with the world’s leading lithography optics, which are used by the chip industry to manufacture semiconductor components. There is global demand for trendsetting ZEISS brand products such as eyeglass lenses, camera lenses and binoculars.

With a portfolio aligned with future growth areas like digitalization, healthcare and Smart Production and a strong brand, ZEISS is shaping the future of technology and constantly advancing the world of optics and related fields with its solutions. The company’s significant, sustainable investments in research and development lay the foundation for the success and continued expansion of ZEISS’ technology and market leadership. ZEISS invests 12 percent of its revenue in research and development – this high level of expenditure has a long tradition at ZEISS and is also an investment in the future.

With over 34,000 employees, ZEISS is active globally in almost 50 countries with around 30 production sites, 60 sales and service companies and 27 research and development facilities. Founded in 1846 in Jena, the company is headquartered in Oberkochen, Germany. The Carl Zeiss Foundation, one of the largest foundations in Germany committed to the promotion of science, is the sole owner of the holding company, Carl Zeiss AG (status: 31 March 2021).

Further information at www.zeiss.com

ZEISS Research Microscopy Solutions

ZEISS Research Microscopy Solutions is the world’s only one-stop manufacturer of light, electron, X-ray and ion microscope systems and offers solutions for correlative microscopy. The portfolio comprises of products and services for life sciences, materials and industrial research, as well as education and clinical practice. The unit is headquartered in Jena. Additional production and development sites are located in Oberkochen and Munich, as well as in Cambourne (UK) and Dublin (USA). ZEISS Research Microscopy Solutions is part of the Industrial Quality & Research segment.