If you work in manufacturing or quality control, you must ensure products meet quality expectations before pushing them to your clients. You’ll have satisfied customers, a great recipe for continued business, and profitability. One way to ensure the products you manufacture meet a client’s exact specifications is with an AS9102 FAIR (First Article Inspection Report).

What is a First Article Inspection?

Many people often fall for the name, believing an FAI entails inspecting the first parts off the production line. First Article Inspection is about inspecting items within the initial batch, and the personnel conducting the process often pick the items randomly. So, an FAI doesn’t necessarily mean you inspect the very first item on your production list.

An authorized person in your company or a second-party inspector with the requisite laboratory and specialized measuring equipment, samples one or several parts from the initial production run. They inspect them by comparing the selected items against client specifications, usually critical dimensions found on ballooned drawings, to determine if they match exactly. The results are recorded on an AS9102 form.

Inspectors won’t have to visit or make calls to your clients – the AS9102 form is enough. It contains all the important data, so it becomes the main reference point in the entire process. Inspectors can use it to verify the selected items to see if they meet your client’s criteria. This is to ensure everything ticks, and production can continue.

What Happens if a Part Fails the FAI?

Before the FAI test concludes, production pauses as the inspectors check the parts in accordance with the laid framework. If they pass the test, production resumes. But what happens if the component happens to fail the test?

If one or more of the selected components fail the FAI test, production will have to cease until the failure is addressed. The responsible parties assess the production to discover the cause and take corrective measures. Another FAI takes place to ensure the components are now compliant.

When is a First Article Inspection Conducted?

While it’s important to understand why you need an FAI test, you also need to know when it may be needed. Here are the times you need an FAI test:

1. During the first production run

Before you embark on mass production for the wider market, you need to ensure your parts or components meet client expectations. You’ll need to pause production and conduct a FAI on the first article to be sure you’re on the right path. There would be no point producing items your customers won’t like.

2. After a production lapse

You still need to be sure your products meet market expectations after a production lapse of two or more years. Conduct the FAI as part of the activities for restarting production.

3. After alterations

Changes in sourcing, materials, location or tools used in the manufacturing process may also call for a FAI. The test will show that the alterations didn’t affect the quality of the item, or didn’t create any adverse consequences on users, or functionality of the component.

4. After design changes

You’ll need a FAI if a part or one of your products undergoes a design change. The FAI report in this case will break down the differences between the older and newer versions, as well as the original FAI. The test ensures that the latest version still meets customer specifications. The newest version may be better, but it’s not guaranteed clients will need it.

A Vital Part of the Quality Process

The first article inspection is not the only test to perform when measuring quality. However, it can be a vital one during the production of some components. A FAI will provide confidence to your customer that you can meet their needs without making costly mistakes.

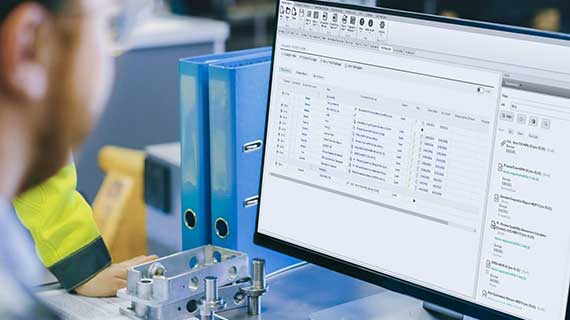

High QA 360 software eliminates paper FAIRs and AS9102 forms, organizes and automates all aspects of first article inspection processes to reduce the cost and time involved – and prevent errors along the way – helping you streamline your manufacturing process and create better parts.

You can partner with High QA for integrated manufacturing quality management software to ensure you get it right every time.

When it comes to the quality of your products, you can never afford to compromise or you risk losing your clients and getting into trouble with authorities.

Contact High QA to learn how to streamline, automate and mistake-proof your AS9120 first article inspection reporting process with our innovative quality management software (QMS).