Aiwa Prosthetics and Orthotics – Japan.

Aiwa Prosthetics and Orthotics Co., Ltd, located in a quiet residential area in Tokyo’s Nerima-ku, produces and supplies silicone prosthetic fingers, hands and feet, all of which are carefully made to order. Since its launch in 2004, the company has been working with medical institutions to provide a range of products to improve the decorative, aesthetic and functional qualities of their products, as well as providing technical training and lectures to promote the spread of their technology and help create a better society.

All Aiwa’s products are made to order. Importing data by reversing the parts on the opposite side of the prosthesis being made allows them to produce a more natural prosthetic limb that is more tailored to each individual customer. This method is very different to ready-made or moulded products and is key to producing a prosthesis without any discomfort.

In order to produce a prosthesis that is as close to the real thing as possible, measurement accuracy is of course a must, especially when it comes to the production of artificial fingers.

The company’s requirement for a reverse engineering solution was clear but complex. “We were looking for a machine able to scan quickly and very accurately as well as detailed enough to reproduce fingerprints,” explains Mr. Hayashi, Representative Director at Aiwa.

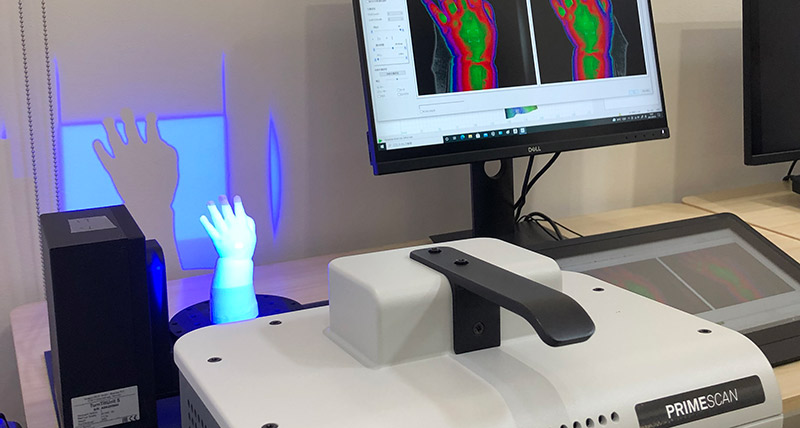

As the company contacted Hexagon for testing purposes, it was clear that traditional metrology tools such as coordinate measuring machines, laser trackers or portable measuring arms did not completely fulfil their requirements. The alternative solution suggested was a combination of a PrimeScan structured light scanner and a turntable, which the customer had been using for some time to improve work efficiency. PrimeScan’s extensive track record in human body measurement, as well as in the field of arts, made it a perfect choice. It is suitable for scanning faces, skin and bodies, as well as reverse engineering skull repairs and scanning teeth marks.

“After a quick test, we were able to obtain fingerprint reproducibility that was clearly different from the previous method,” explains the local Hexagon sales representative who worked with Aiwa on the project. “We were also able to obtain data with much less noise between the fingers, which had been difficult to obtain in the past.”

“Hexagon’s PrimeScan has excellent fingerprint reproducibility, making it easier and more detailed than our previous system, which has improved our work efficiency,” says Mr. Hayashi. “In addition, the quality of the results is always consistent, remaining the same regardless of the skill level of the operator, which means that we can supply our customers with a reliably high-quality product. We have a lot of customers waiting for our products, so it’s great to be able to deliver them as quickly as possible.”

“The ability to reproduce even the smallest fingerprints has virtually eliminated the need for manual corrections,” adds a member of the Aiwa team who has been using the PrimeScan. “The time saving is huge.”

“Depending on the product, the total time required is almost half of what it used to be, resulting in a dramatic increase in efficiency and productivity.” concludes Mr Hayashi.

Depending on the product, the total time spent on the job is almost half of what it used to be, resulting in a dramatic increase in efficiency and productivity.Always looking to the future, Aiwa is planning to actively provide high-quality prosthetics to overseas customers in the future.