The adoption of preventive planning and continuous improvement methods responds to the objective of wanting to create robust products and processes, saving inspections during and after manufacturing by obtaining quality products the first time. For this, various complementary techniques are used in an integrated way. Some are of an organizational nature; others affect production teams or products.

Figure 1: Current manufacturing quality management methods.

Among the former, manufacturing planning stands out. One of its fundamental aspects is production management. In addition, manufacturing planning includes the analysis and optimization of production lines and processes.

There are techniques that ensure the execution of the manufacturing without defects through detailed knowledge and the improvement of the operation of the equipment. The verification and periodic adjustment of the precision of the machines allows to extract the maximum benefits from them. Maintenance avoids unexpected stops and their effects.

Quality control of processes and products uses numerous techniques. Machine and process capability analysis ensures stable production with statistically fit quality to design. Taking representative samples is essential for the speed and economy of the inspection.

Statistical control of processes and decision-making on the acceptance, rejection or recovery of products, or streamlining of sampling. After manufacturing, the quality control of the product, through inspection and measurement, shows whether the product specifications are met. Total Quality Management offers other methods for continuous improvement.

RELATIONSHIPS BETWEEN METROLOGY AND MAINTENANCE

The total production of a model or series is made up of batches of products. Samples are drawn from each lot and will be inspected. The statistical process control system compares the result of this inspection with the quality specifications. This allows the classification of batches and / or products and their subsequent treatment.

Furthermore, given that said result (or that of a verification), reflects the state of the machine, it may indicate the need to carry out operations on it (tool change, adjustment, repair, replacement…).

Figure 2: Quality assured production chain: agents, actions, objects.

The figure shows the chain of agents, resources and actions that ensure the supply of products of traceable quality to the highest levels of precision.

The relationship with quality control processes and instruments (inspection and measurement) is appreciated. Verification, adjustment or maintenance use many calibrated instruments, and are processes focused on production equipment.

VERIFICATION AND ADJUSTMENT OF MACHINES AND PRODUCTS.

Manufacturing quality, first-time products requires the use of well-known, precise, and well-adjusted equipment. Verification analyzes the errors present in a computer, and the adjustment corrects them later to improve its work capacity.

Until the implementation of planning and quality manufacturing, quality control prevailed. Corrective maintenance was employed and prevention or prediction was rarely considered. The classic trial-error-correction method required the elaboration of pre-series of increasing quality until the proper fit was achieved.

Time, material and manpower were wasted in these operations. The trend was to group small orders into a larger one to reduce the need for adjustments. This resulted in excessive levels of storage and immobilized capital.

Against this, physical knowledge of the mechanisms that cause errors in production equipment replaces product testing. All the activities of the company are considered in an integrated way, establishing the design-manufacturing-quality chain.

The designer completes the product development with adjustment and maintenance instructions and incorporates set points into the equipment. The mastery and cheapness of automation allows the development of operational adjustments instantly, providing enormous flexibility. The user effortlessly launches individual, personalized, quality-assured batches.

The inevitable errors, if known by calibration or verification and compensated by correction, are no longer an obstacle to quality. Simple, familiar equipment is preferable to sophisticated, unfamiliar equipment. The training of operators and users will determine the acquisition, conservation and use of the equipment.

A) TYPES OF VERIFICATION AND ADJUSTMENT.

Depending on the purpose of its performance, there are verifications or adjustments of intercomparison or selection, receipt of equipment, audit, maintenance or periodic tuning.

Its place of performance may be the factory of the equipment, in an initial or original verification or adjustment or the user’s facilities after the installation of the equipment.

The study can refer to individual components, subassemblies or teams.

Sometimes a vacuum verification of equipment is carried out, which may include, for example, its geometric, kinematic, static, thermal analysis … However, its verification on load or functional may be necessary.

Due to their importance, the most frequent and developed verification and adjustment operations are those aimed at machine tools, industrial robots and coordinate measuring machines (MMC).

The connection between the functions of the quality and maintenance departments is therefore clear. The quality department schedules the verifications within the framework of a preventive maintenance plan for the machines.

An important advantage of the verification of computer-controlled equipment is that the results or errors of the verification can be memorized as corrections in the corresponding control, thereby improving performance.

B) VACUUM VERIFICATION.

The verification in vacuum requires carrying out, from the kinematic chain of the machine, the individualized analysis of each degree of freedom. Subsequently, the error composition laws are applied to obtain global errors under any load conditions of the equipment. It is a universal but complex method.

C) FUNCTIONAL VERIFICATION.

The work in load of many machines involves high powers and subjects their components to real operating conditions (forces, vibrations, temperature, etc.)

Hence the need to carry out a functional verification, consisting of a test in which standard specimens are manufactured and measured, such as those defined in the VDI 3254/3442, NAS 913/978/979, UNE 15-318-90 or NF standards. -E-60-100. The approximation of these tests to real conditions allows to compare equipment in a simple way.

Stability and process capacity tests.

Today the need for Quality Assurance is spreading, justifying to the client the correct relationship between process capacity and machine capacity in relation to the tolerance required of the parts.

Although the manufacturing quality of a machine drifts over time, its periodic maintenance restores acceptable operating conditions before exceeding the manufacturing tolerances on the parts, also extending the life of these expensive machines.

In repetitive manufacturing, aimed at obtaining long batches or runs, occasional statistical tests of the performance of production equipment may be appropriate. Due to their depth and duration, these tests are halfway between the aforementioned verification or maintenance tests and those for sampling and statistical process control.

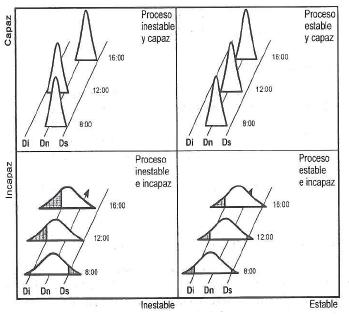

Its evaluation takes place by means of certain indicators and statistical techniques. Stability is an indicator of the temporal evolution of the distribution, while capacity quantifies the relationship between the uncertainty of the process and the tolerance allowed in design.

To evaluate the capacity, two parameters are used, which reflect the narrowness of the distribution and its margin or reserve up to the corresponding tolerance limits.

Figure 4: Stability and capacity of a process.

CONCLUSIONS.

Although quality management activities are increasingly moving towards pre-manufacturing areas, those that affect manufacturing are of great importance.

The verification, adjustment and maintenance methods of the production systems guarantee quality products, even in short series, avoiding tests and adjustments. Periodic studies of the process and machine capacity make it possible to control that the setting conditions are kept within the specified limits. In addition, statistical process control techniques monitor manufacturing quality during long series production.

At Nexon Automation we can help you have 100% quality control with our automated inspection solutions, along with Creaform technology. Contact us!