After wreaking havoc on our families, the economy, and the overall social fabric of countries around the world, COVID is abating. Or at least we are learning to live with a pandemic hanging over our collective heads. According to an article in Deloitte Insights, the North American economies are recovering, and demand is ahead of pre-COVID levels. All good – but what about manufacturing labor? When COVID exploded in March 2020, we were struggling to find workers, skilled or entry level, for manufacturing jobs in all industries. And where are we today? Deeper in the hole!

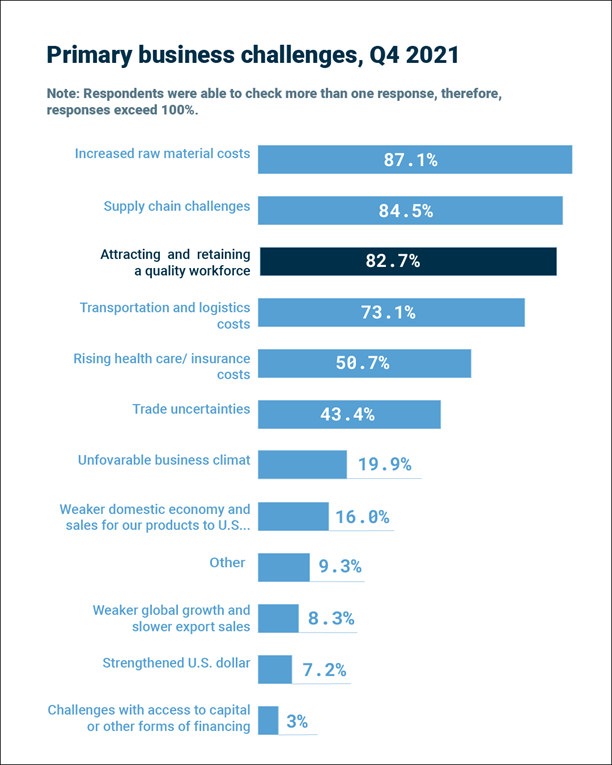

In March 2020, finding and retaining a quality workforce was the #1 problem reported in a survey by the National Association of Manufacturers. Flash forward to January 2022 and that issue has dropped to #3, exceeded only by supply chain challenges and increasing raw material costs. But labor remains a significant challenge, with 85% of the survey respondents reporting open positions that they are unable to fill.

Source: National Association of Manufacturers

In January 2020, the Bureau of Labor & Statistics reported 480,000 open jobs in the manufacturing sector. By November 2021 that number had INCREASED to 858,000 open manufacturing jobs. Many attribute this to the Great Resignation, which certainly has had some impact. But that’s not the whole story. Consider these drivers:

SHRINKING MANUFACTURING WORKFORCE

In 2019, Deloitte found 27% of the manufacturing workforce was 55 years or older, and the Boomer generation continues to retire at the rate of approximately 10,000 per day. Unfortunately, Millennials and Gen Xers and Gen Zers show very limited interest in working in manufacturing. In short, Boomers are leaving manufacturing faster than younger generations are entering. And this is complicated further by the skills gap. Deloitte and The Manufacturing Institute in a 2021 analysis reported 36% of new entrants to the job market (or their parents) had no interest in industry, and 38% had misaligned expectations. And this is on top of a lack of STEM education and effective job training programs.

COVID’S IMPACT

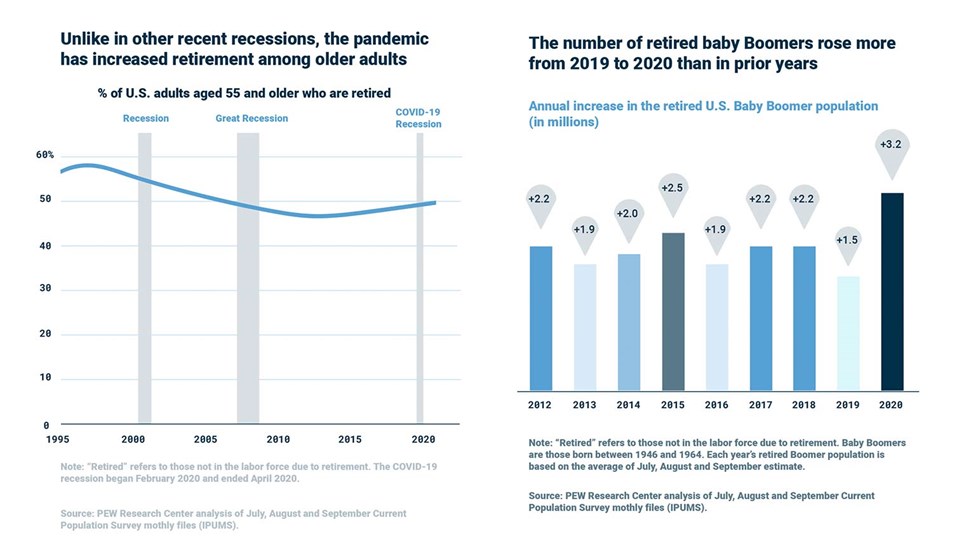

Covid has encouraged the Boomer manufacturing workforce to retire at an even faster rate. A Pew Research Center analysis showed that unlike the recession of 2002 and the Great Recession, retirements accelerated after the COVID recession. An additional 1.7 million Boomers retired in 2020 compared to 2019, and the Federal Reserve Bank of St. Louis reported that number continued to climb in 2021 to a total of 3 million additional Boomer retirements.

UNEMPLOYMENT?

In February 2020, the BLS reported US unemployment at 3.5%, which quickly ballooned to 14.7% by April 2020. By December 2021, unemployment had collapsed back to 3.9%, and is projected to drop further. A January 2022 column in Forbes projects 3% unemployment by 2023, the lowest in 70 years. It is worth noting that many economists consider 4% to be full employment. A key issue is the Labor Force Participation rate, which remains stuck at 61.9% versus 63.3% pre-pandemic. A 1.4% differential may seem minor, but it equates to a drop in the workforce of approximately 1.4 million workers.

Processed Metal Innovators in Wisconsin had to “no quote” work due to lack of welders. UR10e powered cobot welders now enable the company to bid competitively and get orders in the door.

LONG TERM

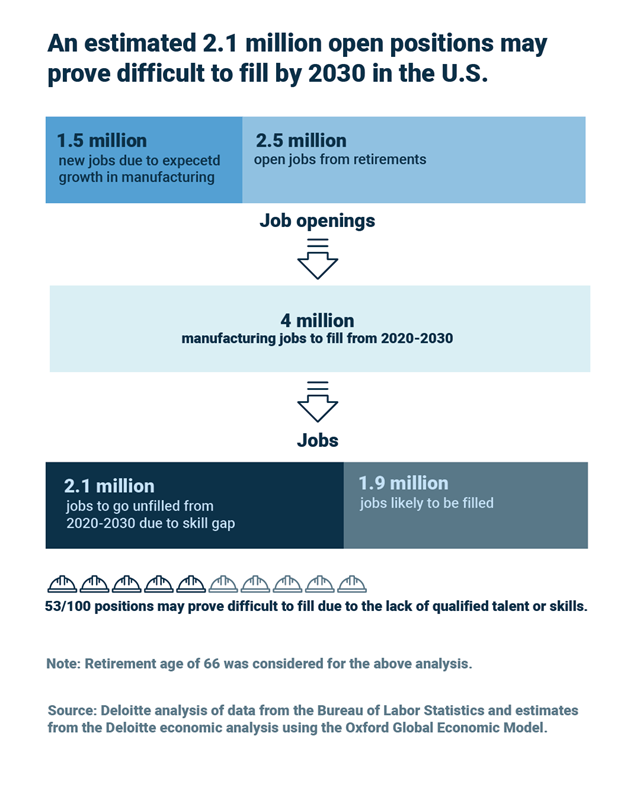

The demographics of the manufacturing labor situation are not pretty, and the challenges will continue. The article in Deloitte Insights projects a gap of 2.1 million unfilled manufacturing jobs by 2030 due to a combination of skills gap and the stagnant workforce.

WHAT TO DO?

Increasing interest in STEM topics in schools is a sound initiative to introduce students to the core technologies, and to build awareness of career opportunities. Job training programs, including 2 year manufacturing technology programs will also shrink the skills gap and expand the manufacturing workforce. But these are long term efforts, taking years to put in place and generate significant results.

So, what options do manufacturers have for the short term and into 2030? Consider collaborative robots as your primary automation building block and start to automate your manufacturing operations.

“We find that we get a a real sparkle in people’s eyes when we say ‘We’ve got a robot on the crew.’” Watch how MT Solar in Montana uses UR cobots to optimize welding processes and attract talent.

WHY COBOTS?

- Low installed cost enables even the smallest shop to automate. Unlike traditional automation, collaborative solutions have successfully stripped costs out of every phase of a typical project. It is common now to see complete systems in machine tending, welding and palletizing deployed for less than $100,000, often less than $85,000.

- Cobots enable Incremental Automation. Unlike the traditional all-or-nothing approach, the ability to safely deploy cobots side by side with skilled operators allows a single station, machine or process to be automated. Automate one cell, generate ROI, and then proceed to incrementally automate more operations.

- Cobots are quick to deploy (see #1 above) and quick to re-deploy, making them perfect for high mix / low volume operations.

- Best-in-class cobots are easy to program, and do not require dedicated teams of engineers and programmers.

NOW, WHERE TO START?

- Fill the gaps. If you are struggling to hire welders, machine operators, pack line workers or other roles, invest in cobots to fill the voids left by the manufacturing labor crisis. The installation of a $85,000 cobot tending a machine tool addresses both the labor shortage and the low machine utilization – a double improvement to the bottom line.

- Automate DDD applications – Dull, Dirty, Dangerous. These positions are the most difficult to hire and automating them will improve job satisfaction and worker morale.

- Make manufacturing attractive. See #2 above and recognize that the hesitancy of younger generations to enter manufacturing careers is directly proportional to their view of DDD jobs. Cobot automation can change the overall image of your manufacturing floor and make it easier to recruit qualified candidates.

- Automate the simple, repetitive, dull tasks. Move skilled workers into higher value assignments.

- Leverage cobot flexibility. Look for areas where automating high mix / low volume processes can increase capacity and reduce costs.