Throughout history, the methods of creating and producing things have changed continually. Especially in the past 200 years the ways products can be designed and manufactured have changed dramatically and have had a severe impact on not only the materials processed but also the client´s perception of a product. What we experience today is an increasing demand for personalization of products, first of all in the realm of consumables but increasingly in other areas too, as the following example of customized furniture is teaching us:

Voxel 3D, experienced in Reverse Engineering and Metrology for more than 10 years is focusing on selling 3D Digitizing equipment and offering scanning and production services. One important branch business is the combination of 3D Scanning and Wood Carving CNC for the furniture manufacturing industry. Having successfully completed a broad series of such CNC furniture projects, Voxel 3D has become a renown institution offering not only 3D digitizing, furniture design and production services to their customers but also commercializing the solution from 3D Scanning, Design and wood carving the furniture by means of a CNC machine.

Having majored in Mechanical Engineering in university and experience in Metrology & Reverse Engineering, Mohamad Khalaj Amirhosseini, the founder and owner of Voxel 3D understood early the importance of a reliable, competitive and accessible 3D digitizing product, not only for his own company, but also to offer to his customers and project partners for resale. Since 2010, when the business relationship with SHINING 3D was established, the company is championing the versatility of EinScan 3D Scanners to customers and business partners and are a regularly referred to expert when it comes to SHINING 3D products in their region.

“We chose SHINING 3D due to the excellent price-performance ratio for the manufacturing industry and due to their excellent aftersales service and guarantee. Their outstanding support helped us to become a confident representative of their brand.”

Mohamad Khalaj Amirhosseini

Digitizing furniture objects with the EinScan Pro 2X Plus

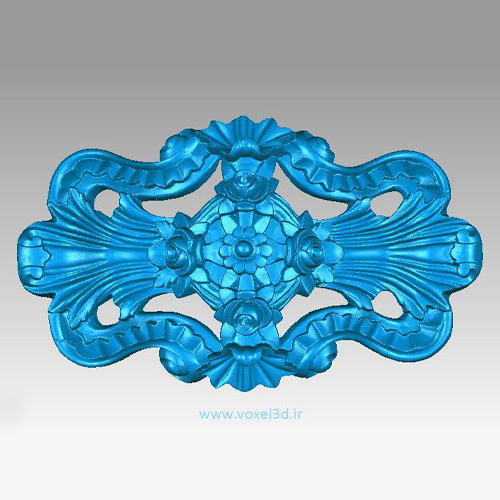

First of all the parts to be digitized are being cleaned and if they have a shiny surface they are prepared for scanning with developer powder. Then they are scanned with the EinScan Pro 2X Plus Multifunctional Handheld 3D Scanner.

After the Scanning process is finished, the mesh files are edited in Geomagic Studio. Holes are being filled, surfaces are being smoothened, edges sharpened and the object scaled based on the project´s requirements. Finally the project is saved as an STL file for the production process of the CNC furniture.

Production of the CNC furniture

The obtained STL file is imported in the Autodesk powerMILL software and the CNC furniture is carved out based on the G-code the STL file has been converted to. After the carving process, the furniture pieces are cleaned and assembled by professional carpenters and finished off with color and textile coverings.

About Voxel 3D

After successfully selling SHINING 3D´s Metrology and 3D Digitizing products for 5 years, Mohammad Khalaj Amirhosseini founded his own company, Voxel 3D and started working with SHINING 3D independently. He has become a renown business partner of the SHINING 3D brand in his region focusing on Reverse Engineering Equipment Sales, 3D Service, Industrial Scanners and 3D Printers always educating himself on the latest technology and expanding to new industries. Voxel 3D´s service in the furniture industry can be resumed in two pillars, 3D scan and furniture design service and resale of 3D scanning equipment in combination with a woodcarving CNC machine. Educating customers on the technology and handling of the equipment, aswell as after sales and guarantee service are rounding off Voxel 3D´s portfolio.