Frank Uibel, a long-time expert in the field of press-fit technology and active member of the IPC, recommends Bruker Alicona technology as a “fast, simple and accurate measuring tool” for the geometric verification of press-fit zones. We wanted to know why and asked him these questions.

“Bruker Alicona technology is characterized by fast measurement times, easy handling and high accuracy”

Frank Uibel, expert in the field of press-fit technology and active member of the IPC

What is measured?

Press-fit technology is a special connection technique used to create solderless electrical connections. Contact parts or entire components with press-fit zones are pressed into metallized holes in a printed circuit board. This creates a stable, gas-tight and highly conductive connection between the press-fit zone and the hole wall. There are currently a number of different press-fit zones available that have one thing in common: The geometry is one of the decisive factors for a good connection. From a metrology point of view, the geometry poses a number of challenges. These include the measurement of edge radii, enveloping circles at certain positions or transitions such as that from the press-fit zone to the press-fit tip. Measurements must be available with the necessary accuracy, while at the same time a high measuring speed and documentation of the results are required.

![]()

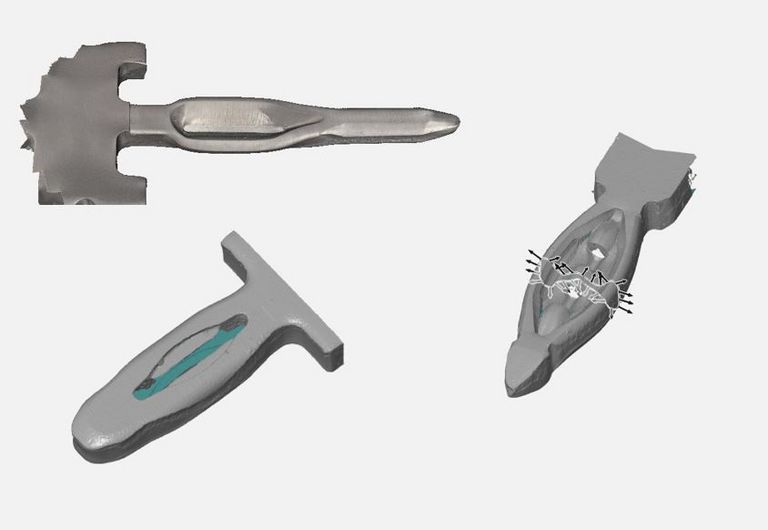

Different press-fit zones have one thing in common the geometry is one of the decisive factors for a good electrical connection.

Why Bruker Alicona?

The InfiniteFocusSL measuring system is a fast, simple and accurate measuring device. Compared to complex and user-dependent methods such as microsection measurement or computed tomography (CT), Bruker Alicona technology is characterized by fast measurement times, easy handling and high accuracy. This allows the dimensional accuracy of the pins to be verified within a short time, contactless in 360° and with a one-button solution. Single measurements can be combined to a full 3D measurement of the pin. Deviations from the CAD data set can also be easily determined via difference measurement. Soon the new “IPS 9797-Press fit Standard for Automotive Requirements and other High-Reliability Applications” will be published, in which the optical dimensional measurement of the press-fit zone is included.

![]()

Complete (360°) and non-contact 3D measurement of a press-fit zone with “Real3D” technology, measured with InfiniteFocusSL. Form deviations from the CAD data set can be easily determined by the “difference measurement”.

How are pins manufactured?

Contact parts with press-fit zones are manufactured using stamping technology. Measurement technology is already used in toolmaking during production to check the active and passive elements. Accordingly, tool manufacturers require high-precision measuring methods for quality assurance of their milled, eroded or lasered punches with tolerances in the single-digit µm range. Stamping companies in turn use measuring technology for in-process control, while OEMs use metrology for incoming goods inspection. Accordingly, quality tests are carried out at various stages of the manufacturing chain. By saving time and being user-independent, efficiency can be created in the field of measurement technology, which generates a considerable amount of added value in the production process.

Who needs plug contacts?

Plug contacts are used in every manufacturing industry where component groups with integrated electronics are installed. One of the strongest customers is the mobility sector, where the annual production of connector contacts is in the billions. According to Uibel Consulting, at least 1000 press-fit zones are installed in every car. This results in a worldwide demand of more than 50 billion press-fit zones in the automotive industry alone. Developments in other sectors such as sensor-based assistance systems in the medical and care sector are a clear indicator that this number will continue to increase across all sectors.

About Frank Uibel

Frank Uibel has been an expert in press-fit technology for many years. The current owner of Uibel Consulting started his career as a toolmaker, passed through stations in quality management, marketing, sales including sales management. As a managing partner he was additionally responsible for product management for press-fit zones. With his current consulting company “Uibel Consulting” he supports companies in all sales and technical agendas around press-fit technology and galvanic surfaces. Since 2017, Uibel Consulting has been a member of the global IPC trade association, which represents the PCB and electronics assembly industries, their customers and suppliers.