How aptly can a name sit on top of a brand? AAKAR ENGINEERS justifies its name in every sense of its existence. Mr.Rahul N.Rakshe and Mr.Bhanudas V.Ranawade are the brain child behind this spectacular set-up in the heart of Bhosari MIDC, in Pune. It became operational in the year 2001 with a single Vertical Machining Centre(VMC).

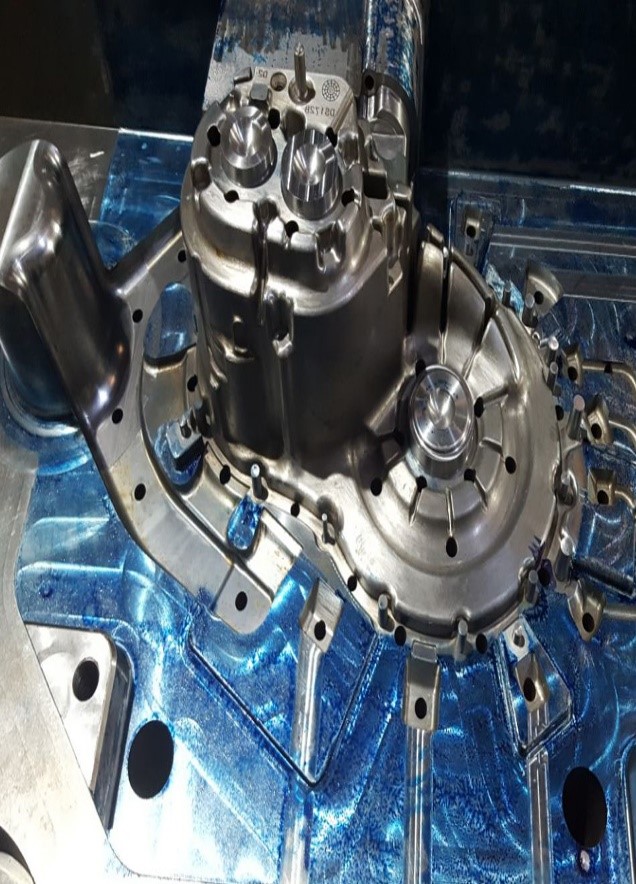

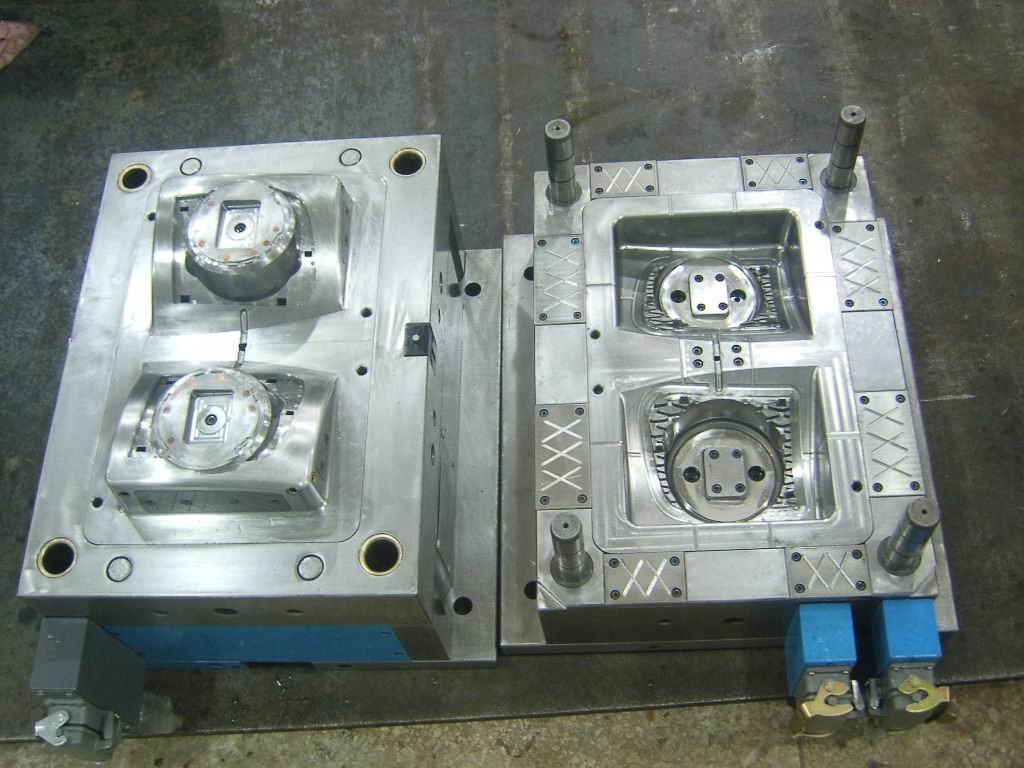

Presently AAKAR ENGINEERS is operating with nine(9) VMC’s; three(3) Electro Discharge Machine’s(EDM); two(2) Faro Arm’s and a GOM Scanner.

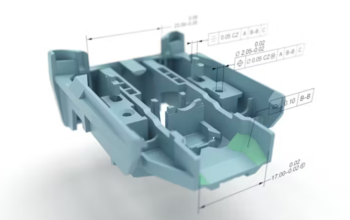

The company has an in-house designing and simulation team, who have mastered the science of implementing every little detail, on the final shape and size of the dies manufactured. The modus operandi adopted by AAKAR ENGINEERS is to get a sample part from the customer and then develop a die accordingly. To increase operational efficiency, the company has outsourced grinding and milling operations of the dies. Bajaj Auto and Mahindra&Mahindra(M&M) are the only customers serviced at this point of time. 10% of the orders are from Bajaj Auto and the rest are from M&M.

Aakar Engineers is a manufacturer and supplier of Dies, Moulds and Foundry Tooling. Products manufactured through its dies are highly appreciated and acknowledged for their best-in-class performance, quality, durability, reliability. A state-of-art infrastructure helps manufacture products at low costs. For rapid production lines, AAKAR has backed itself fully skilled and experienced team of professionals, who work with co-ordination and passion to achieve the organizational goals. The entire team has maintained a fruitful and trustworthy relationship with its clients, which is the key to its success and growth in competitive market.

The company had recorded a turnover of INR 12 Crore (1.6 Million USD) in the last financial year. It had set a target of INR 16 Crore (2.2 Million USD) for the present financial year, But due to COVID-19 scenario, it has had to revise its target to Rs.10-12 Crore (1.4 Million USD to 1.6 Million USD) respectively. It manufactures an average of 10-12 dies per year, with a composite capacity of 1600 tonnage. Mr.Bhanudas has plans of entering the prototype component manufacturing field in the coming days.

When further quizzed about the highest peak of his entrepreneurial journey, Mr.Bhanudas goes on to state that being able ride through the rough waters of COVID-19, without making manpower reductions and paying their monthly salaries on time. He reinstates that every person working in the company is a family member and they are the biggest asset that he wants to hold on to.

For further information please refer to the details below: –

AAKAR ENGINEERS

Plot No. J-510,

MIDC Area, Bhosari,

Pune – 411026,

Maharashtra, India

Email:

rahul@aakarengineers.co.in ,

bhanudas@aakarengineers.co.in

Website: