NORTH STAR IMAGING BLOG by ERIC GINGRAS

In traditional cone-beam X-ray Industrial Computed Tomography (CT) scanning, an x-ray source is used to penetrate various objects. During the acquisition process, x-rays pass through the object, ultimately reaching the X-ray detector and producing a two-dimensional radiographic image. A typical CT project can generate thousands of 2D images which are then collected and used to generate a 3D volumetric reconstruction of the internals and externals of the object (see figure 1).

Figure 1

To maximize image quality, our X-ray engineers consider several factors when developing a specific CT technique. The focal spot size of the X-ray tube, geometric magnification, detector size and pixel-pitch, and contrast, are all major considerations. All these factors pose a significant challenge for traditional cone-beam CT scanning techniques when high resolution is necessary to achieve the overall objectives of the project.

A traditional cone-beam CT scanning technique will often drive enough fidelity. However, what about those applications where it is not possible to achieve a small enough voxel with a single CT scan? NSI has solved this problem by developing an advanced scanning technique called SubpiX. When limited by a given detector, physical part size, or size of the area of interest, this advanced technique allows the user to attain an overall higher fidelity scan during the acquisition process. SubpiX uses a motion system which slightly shifts the X-ray detector horizontally and vertically, essentially splitting each pixel into 4 quadrants or in some cases 9 quadrants, effectively doubling or even tripling what the detector alone is capable of producing (see figure 2).

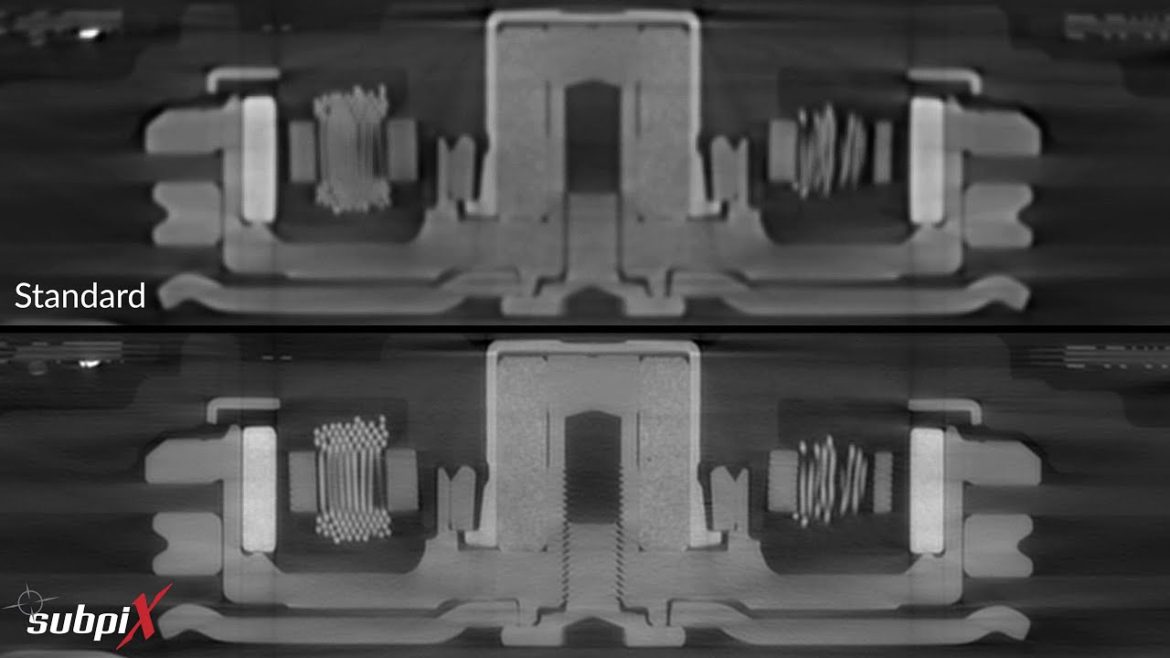

For example, Figure 3 shows a cross-section of an electronics board within a cell phone that had approximate dimensions of 138 x 67 x 7 mm. The objective of the CT project was to identify solder consistency beneath mounted components on the board.

Choosing to use SubpiX in this application provided visibility of finer features and smaller details. This proprietary North Star Technique can also significantly improve spatial resolution as demonstrated in figure 4.

Figure 4. Standard Line pair gauge comparison

Subpix also offers a clear advantage when the goal is to utilize CT imaging to identify small indications in an Additively Manufactured (AM) part (see figure 5).

When our X-ray engineers are challenged with producing a high-fidelity CT scan on a part that limits the amount of magnification that can be achieved, they often turn to North Star Imaging’s proprietary technique called Subpix. Subpix utilizes sub-pixel movement during the acquisition process, drastically improving image quality.

For more information , please refer https://4nsi.com/