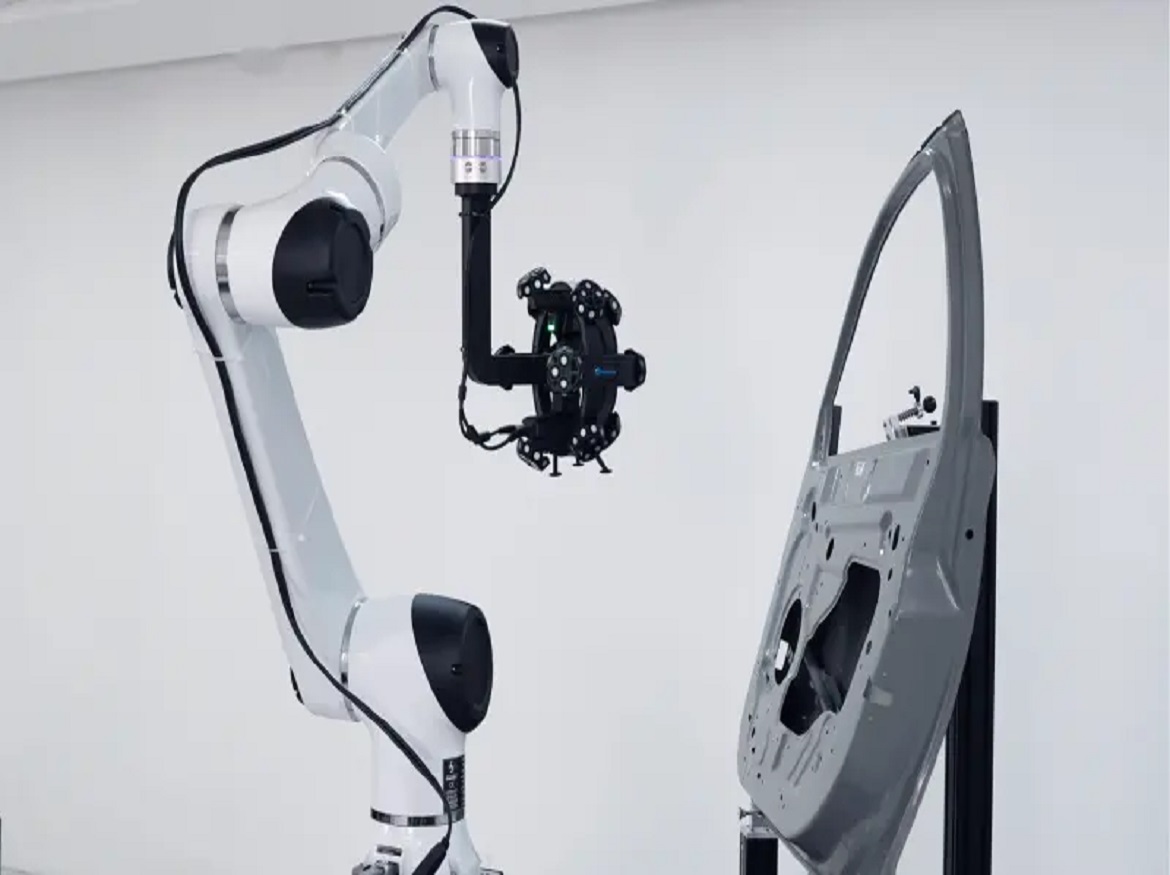

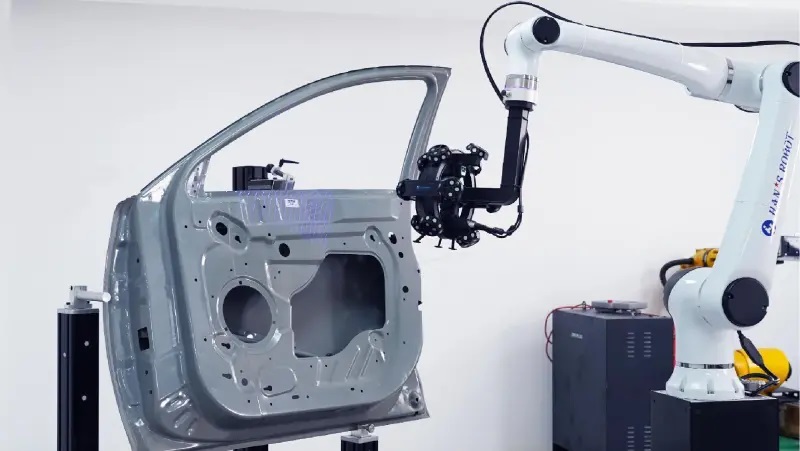

The newest optical automated 3D measurement system AM-CELL C200 for medium-sized parts is introduced by Scantech, a global 3D measurement firm that specializes in the development, production, and sales of 3D scanners. This system advances automated measurements.

Our engineers and designers work diligently to create this standardized product AM-CELL C200 with a modular design and simple operations, which is user-friendly for both engineers and operators, in an effort to lower the barrier of automated measurement.

Introduction of AM-CELL C200

For manufacturers to take corrective action and ensure the quality of manufacturing, it is crucial to quickly discover, assess, and eradicate quality issues. Applications for the AM-CELL C200 in manufacturing work well.

It can be quickly assembled and transported thanks to its modular construction, and it can be installed in two days. To prevent safety hazards, the cell is built with an active safety system and servo-mechanists with force feedback.

It is the perfect solution for use on the shop floor, in CMM rooms, and in educational settings because it can be powered by readily available mains energy and is secure enough to operate right alongside the operators.

It can speed up the production, inspection, and repair processes with accurate measuring data and understandable GD&T variances. It provides a fully automated measuring solution for life-cycle quality control, allowing businesses the opportunity to advance their operations through increased automation and smarter manufacturing.

Features of AM-CELL C200

Lightweight Standardized Product

A standardized 3D solution for measuring parts for product development and inspection, the AM-CELL C200 weighs only 30% as much as its predecessor. Its components can be easily combined to create the final system in under two days by a single operator.

The bar for professional operations is lowered by this plug-and-play system, which allows labor-free automated measurement and manual robot education for efficient path planning.

Modular Design and Flexible Layouts

The C200 may be deployed in L-shaped, I-shaped, T-shaped, and independent layouts to fit in a variety of working environments thanks to its modular functional design and modest footprint. To enable versatile measurements, a variety of external devices can be attached to its standard ports.

Several positioners can be used along with its cobot so that workers can change the part on one positioner while the others are in use. As a result, producers can drastically improve measurement efficiency by minimizing downtime.

Innovation to Keep You Safe

An active safety system is built into the system. To prevent safety problems, its robot and turntables are outfitted with servo-mechanists with force feedback.

As it has 10-grade collision detection, a physical fencer is not necessary. Consequently, the safety of both human operators and measurement equipment can coexist in the same space.

Intelligent 3D Optical Measurement

The C200 can automatically measure parts without sticking targets and is compatible with Scantech’s TrackScan-P series optical tracking 3D systems. Users may measure hundreds of parts effectively and steadily with predictable results thanks to its improved stability.

Automatic edge inspection is possible with the C200, and accurate findings are guaranteed by its sophisticated grey value measurement. Using the website, users can get precise 3D data about closed features like holes, slots, and rectangles of stamped parts and machined parts.

- Accuracy of up to 0.025 mm

- Measurement rate of up to 2,600,000 MPs

Information-driven Quality Control

The C200 can be used with numerous MES systems and automated quality control programs used in industrial manufacturing.

Users can invoke templates, calculate data, produce inspection reports, and evaluate statistics with the push of a button to acquire insights that can improve production efficiency and guarantee accurate quality control.

- For R&D: The C200 has a measurement rate that is 5 times faster than typical CMM, which is necessary to speed up research and development, shorten ramp-up times, and shorten the time it takes for new goods to reach the market.

- For Manufacturing: It offers batch inspection trend analysis as well as single-part and multiple-part inspection. Users may track the development of batches in this way, foresee the trend of defective goods, lower the rejection rate, and guarantee to manufacture stability.

Vast Applications Deliver New Experiences

- Maximum Object Size: D=Ф1500mm

- Object Payload: 200KG (medium-sized parts)

- Power Supply: Mains electricity

Shop Floor: Regardless of changes in temperature or lighting, measurements can be taken directly on the shop floor using the measuring cell. It can accurately measure items in challenging shop floor circumstances.

CMM Room: The system can operate steadily and safely without the need for any specific configurations. Depending on the needs of the users, physical fencing is optional.

Educational Settings: Teachers and even students with little programming experience can quickly learn how to use the measuring cell securely with the help of a variety of programming techniques.

It demonstrates our dedication to integrating industry, universities, and research in order to cultivate a talent cultivation ecosystem.

Click on the following link Metrologically Speaking to read more such news on Metrology.