Rigid parts, among the many trim parts made by Vi-Technik, have stricter requirements for dimensional accuracy than soft parts and necessitate a tailored method of inspection. This demand can be satisfied by the Kreon Ace measurement arm.

Plastic injection parts made on-site can have geometric flaws such as voids and distortions that occur during cooling and are likely to prevent them from meeting geometric requirements. Since it makes the defects evident to the human eye, the Ace measuring arm is especially helpful during the fine-tuning phases. The Ace measuring arm makes sure that the machine configuration is ideal and that the components series is prepared to be made under ideal circumstances. The injection is a complicated procedure.

To ensure that there are no errors and that the quality is being upheld, inspections are also done while the product is being produced. Reports are produced by PolyWorks Inspector for internal use. In order to continuously enhance the production processes, data is used statistically. Throughout the development process, clients are also kept in the loop with the reports.

It is occasionally possible to build support for the parts that are most vulnerable to distortion from the weight. To isolate any manufacturing flaws, the part is just put on the support without any restrictions. This procedure guarantees repeatable, high-quality inspections.

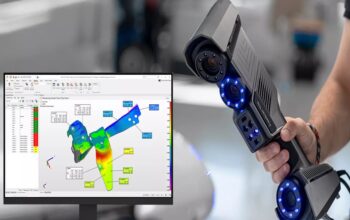

Particularly, the Skyline Open 3D scanner-equipped Ace measuring arm is used to inspect the parts. This scanner provides precise acquisition that is catered to the requirements of the plastic parts and a good scanning speed. With the aid of a colored map, the operator quickly scans the entire part and compares it to the PolyWorks CAD model. Only a few minutes are needed for such a thorough part inspection.

Click on the following link, Metrologically Speaking to read more such news about the Metrology Industry.