3D Scanning Streamlines Measurement Workflows and Increases Efficiency

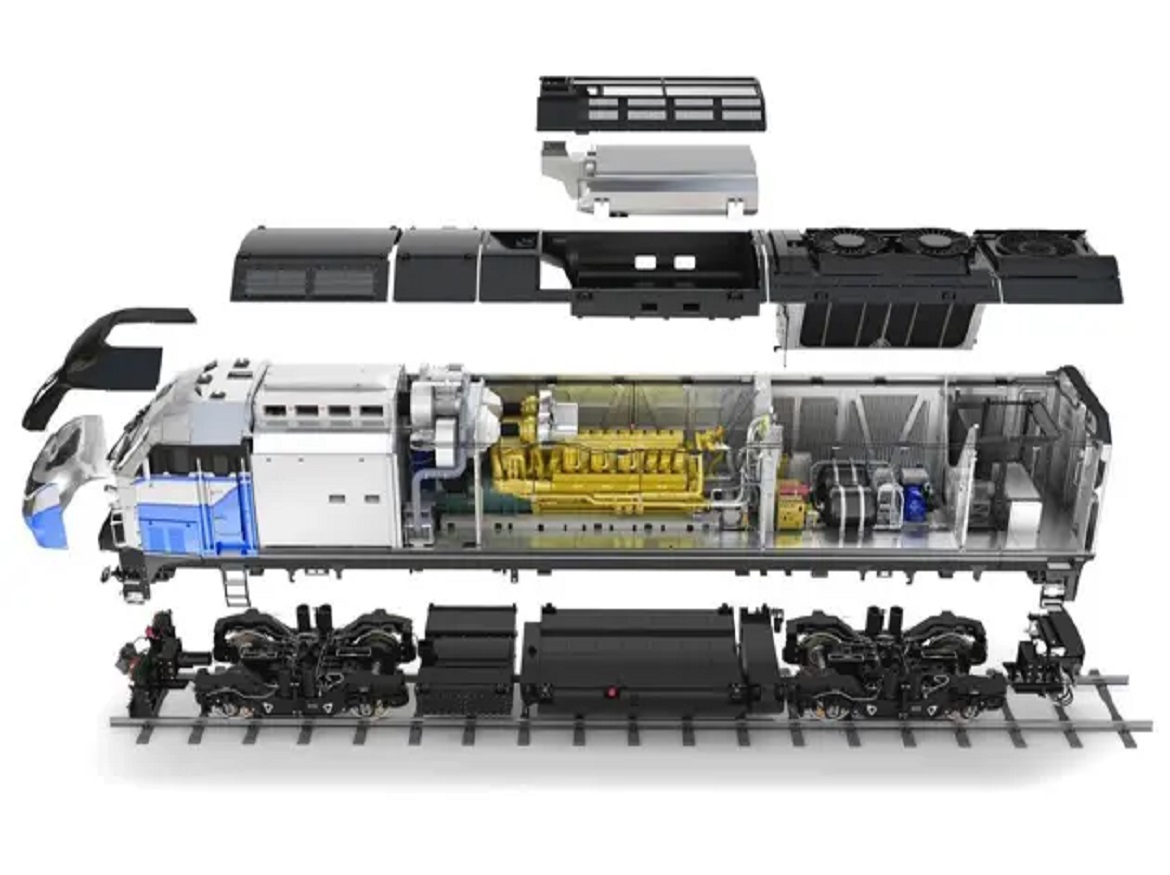

One of the most popular and environmentally beneficial modes of transportation is trains and subways. For international trade and goods, ships and boats are necessary. To prevent malfunctions and guarantee error-free processes, even the smallest parts of these vehicles and vessels, such as clamps and connectors, must adhere to exacting requirements. Manufacturers and engineers want precise and efficient production management as well as cost-effective maintenance and repair to guarantee the high performance of modern transportation vehicles.

To measure the intricate dimensions of parts and even entire train body shells and ship hulls, Scantech offers optical measurement devices such as the handheld 3D scanners KSCAN-Magic and automated 3D measurement systems AM-DESK. Our 3D solutions are non-contact and non-destructive, so they can accurately measure the parts without inflicting any harm to them. The 3D data collected can be used as a resource for maintenance, reverse engineering, product creation, and more.

Portable 3D laser scanners with extremely fast measurement rates can help to streamline manufacturing, enhance inspection procedures, and save downtime while undergoing maintenance. We are able to assist users in saving priceless time and money because of the high-precision measurement results and portability of 3D scanners.

Product Development

Parent boats can serve as models for the structure, hydrostatics, and strength of new ships and subway systems. When there are no technical blueprints, it takes a lot of time to measure these large-scale vehicles using conventional tools like rulers and tape measures. Portable 3D scanners can efficiently record changes made during design and accurately capture 3D data of parent vessels to enable quick product development.

Quality Control

Large rail vehicles and ships have intricate geometry and strict precision requirements. Due to the limitations brought on by limited skill levels and complicated shop-floor conditions, the vehicle dimensions invariably depart from the nominal values. For effective quality control, it is advantageous to utilize 3D scanning to collect exact and quantifiable data about ships and trains.

MRO

The modern transport sector needs maintenance and repair that is accurate and effective. For these rail cars to remain mobile over the course of their full lifespan and maintain passenger safety, routine, and thorough maintenance is necessary. Scantech offers accurate, reliable, safe, and reliable measurement systems. Engineers can greatly save time for maintenance and repair by using quick measurement tools.

Efficient and NDT Measurement for Trains and Ships

Scantech’s 3D scanners allow manufacturers and engineers to inspect ships and trains that are constructed of varied materials and have distinct features. Subway body shells, ship hulls, and other components can be checked to make sure they are of the highest quality using optical and non-contact 3D laser scanning. Operators and engineers can measure parts regularly and effectively with 3D scanning, and they can compare the 3D model to the original CAD to detect GD&T.

Yacht Design

Scantech can assist in redesigning yachts to follow the most recent design trends with the use of highly accurate 3D scanners. When there is no sketch available, it won’t be a problem because 3D scanning can capture the entire geometry of the yacht. Using specialized 3D software, designers can create 3D models that are ready for additional design. Users may properly measure the ship without accumulating a lot of alignment mistakes thanks to KSCAN-Magic’s built-in photogrammetry and big scanning area as large as 1440 mm * 860 mm. The entire boat must be scanned, which takes roughly an hour.

Ship Component Inspection

Scantech offers 3D quality inspection services to assist manufacturers in maintaining the caliber of substantial ship components like propellers. Users may quickly scan both bright and dark surfaces and receive precise 3D data of workpieces with the optical tracking 3D scanner TrackScan due to its high environment adaptability and target-free 3D scanning technology. To effectively evaluate the quality of components, compare it to the original CAD drawings and provide an intuitive inspection report.

Subway Body Shell Inspection

It is necessary to measure the tube body shell to confirm that all of its dimensions, including the width and length of its doors and windows, adhere to strict specifications. The whole 3D data of the subway hull can be obtained by 3D scanning, along with particular values for important characteristics. The measurement data, for instance, can be used to examine if the mounting holes in the windows and doors comply with the standard and to determine whether they can be effectively mounted. Additionally, the data can be saved and used as a foundation for ongoing maintenance and inspection.

Rail Transport Component Inspection

Manufacturing of pertinent equipment is required for enhanced performance due to the improved technological development of rail transportation. Portable 3D scanners are essential for improving product development and quality control of shipbuilding and rail transportation components. In these sectors, the components, such as structural casting for train chassis, are typically huge with intricately curved surfaces and angles. Measurements can be made on-site using high-precision 3D scanners, eliminating the need for specialized laboratory. Additionally, this technology has a quick measurement rate to do jobs quickly without sacrificing precision.

Quality Control of Railway Prefabricated Bridge Elements

The construction time and quality of railway bridges are directly correlated with railway prefabricated bridge elements, essential components of rail engineering. For the purpose of finding GD&T and deformations, these components must be carefully scrutinized. To develop appropriate criteria for the bridge elements, digital 3D solutions might be used. These substantial workpieces may be promptly and accurately measured using photogrammetry and infrared laser scanning. To demonstrate if these components are qualified, inspection reports are produced.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry