Introduction

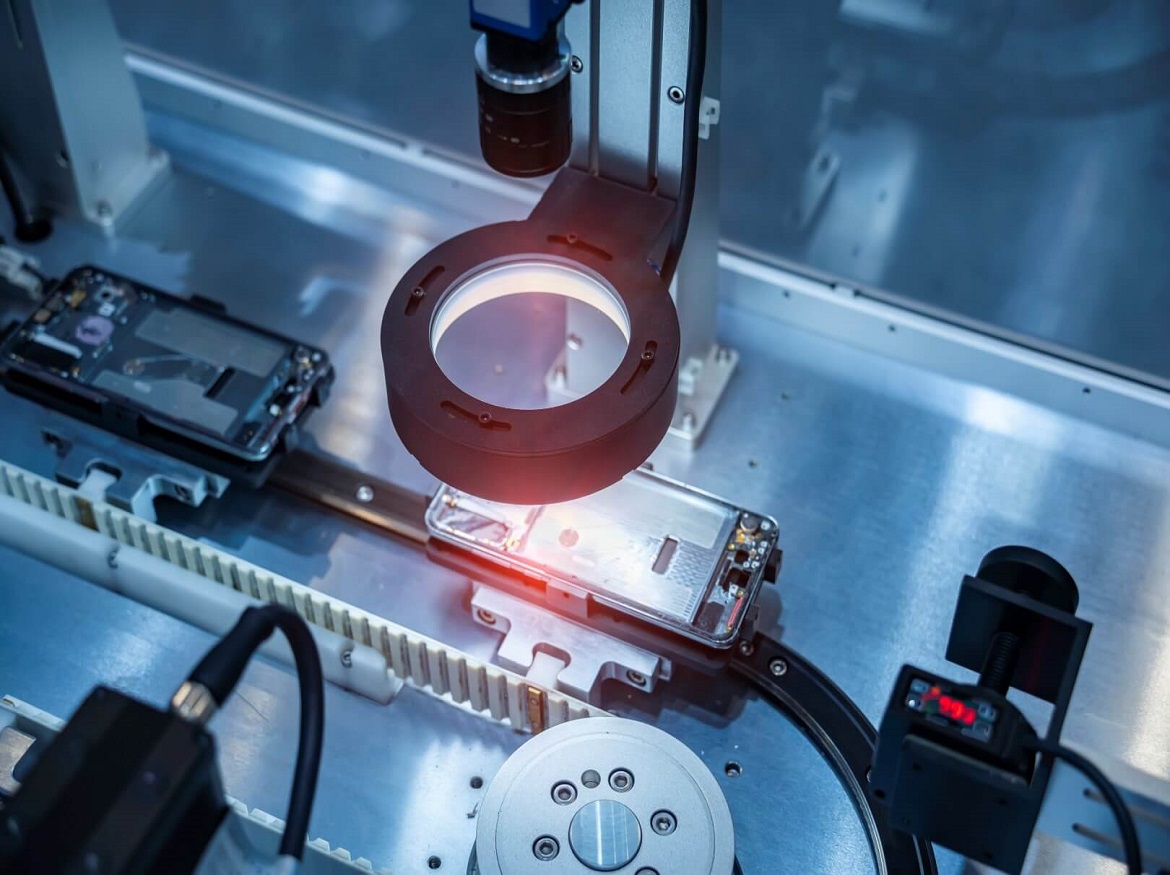

A cutting-edge technique called automated optical inspection (AOI) is revolutionising modern manufacturing. Printed circuit boards, electronics, and medical devices are just a few of the things that the AOI system inspects. Modern image processing algorithms are used to achieve this. The objective of AOI is to identify faults and abnormalities in the production process in order to guarantee that goods meet quality requirements.

A crucial step in the production process that guarantees the dependability and quality of the finished product is visual inspection. Until recently, the only method available was manual human inspection; now, with advancements in technology, automated visual inspection systems have emerged as a more reliable and accurate replacement.

In this article, we’ll compare the automated approach to traditional manual inspection while highlighting the benefits of AOI. We will also provide a brief introduction and talk about the importance of visual inspection in the industrial industry.

Traditional Manual Visual Inspection Systems

As a conventional method of visual inspection to meet the essential standards in production, professional inspectors manually inspected each product to discover flaws and deviations from quality standards for many years. Although manual inspection is still a possibility, there are a number of limitations and drawbacks that could compromise the precision and efficiency of the procedure.

As part of the manual inspection process, a qualified inspector carefully examines each product to search for any faults, anomalies, or deviations from the set quality standards. After using their expertise to identify any issues, the inspector decides whether the product is acceptable. The accuracy and efficiency of hand inspection may be hampered by a number of inherent drawbacks.

One of the biggest disadvantages of manual examination is the constant chance of human error. While trained inspectors have had substantial training and experience, they are still only human and are more prone to error when there are more products to be examined. Additionally, because different inspectors may employ varying inspection methodologies, manual inspection might result in a variety of results. Consistency is a problem as a result.

Additionally, the manual examination could be expensive, time-consuming, and labour-intensive. Due to the slow inspection speed, it may take a long time to inspect large quantities of goods, which slows down the production process. This could result in increased expenses and worse production quality, which would be quite problematic for enterprises.

Enter Automated Optical Inspection Systems

Automated optical inspection is the process of analysing and verifying the quality of manufactured goods using cutting-edge image techniques. In order to automatically detect faults, anomalies, and deviations from predetermined quality requirements, it makes use of advanced software, high-resolution cameras, and AI algorithms.

A reference image that is already saved in the system is compared to photos of the goods that were taken during manufacture by AOI. In order to identify any differences or anomalies, the system compares each product image to the reference image, which serves as the ideal product. The system delivers a warning when the defective product has been identified, enabling the production process to be modified to address the problem.

We will go through each benefit in more detail later. Some benefits include increased speed and efficiency, increased accuracy and consistency, boosting production quality control, cost-effectiveness, and decreased human error. With its quick and accurate product inspection abilities, AOI helps manufacturers maintain high-quality standards and steer clear of costly faults and rework.

Advantages of Visual Inspection Systems

Increased Production Speed and Efficiency:

Time is money in the modern world when getting a product to market fast is essential and business dynamics are always shifting. Manufacturing companies may handle large numbers of items in a fraction of the time required for human inspection thanks to automated visual inspection capabilities, significantly increasing production speed and efficiency.

Improved Accuracy and Consistency:

Second, with the aid of computer vision and robotics, they can swiftly and accurately identify flaws in manufactured goods. Automated visual inspection systems combine a user-friendly interface, state-of-the-art algorithms, and artificial intelligence to ensure accurate and reliable inspection findings. The use of technology eliminates the possibility of human error, which can lead to inconsistent results and assures that every item is inspected to the same high standard.

Enhanced Production Quality Control:

By automatically detecting faults and deviations from quality requirements, the automated visual inspection also helps to improve product quality control and ensure that only high-quality items are produced. And with better-quality products, recalls, media mishaps, and consumer satisfaction all rise.

Cost-effectiveness:

In manufacturing, operational cost is a crucial factor. With an automated inspection system, several labour costs, training costs, and error costs can be drastically reduced. Automated inspection systems are extremely cost-effective since they require little training and function with fewer errors than manual inspection methods, even if organisations may need an expert to manage and administer them.

Reduction of Human Errors:

Human error is a key source of faults and discrepancies in manual inspection processes. Although it may be hard to completely eliminate human error, automating product inspection reduces this risk and ensures more accurate findings. Additionally, the system might spot and emphasise mistakes early in the production cycle, reducing the need for pricey rework and increasing overall productivity.

Automated optical inspection vs. conventional manual inspection comparison

In conclusion, it is simple to show how AOI is superior to traditional manual inspection by contrasting important factors including process accuracy, consistency, speed, and efficiency.

Compared to hand inspection, AOI devices offer a significant advantage in terms of speed, accuracy, and consistency. AOI systems swiftly and accurately inspect goods while lowering the chance of human error and ensuring predictable results. This leads to quicker inspection times, more accuracy and uniformity, and cheaper costs.

Cost savings and a decrease in human mistakes are two other benefits of AOI systems. By reducing the need for manual inspection labour, AOI systems increase productivity and reduce labour expenses. The chance of human error, which can be expensive in terms of faults, rework, and product recalls, is also eliminated by AOI systems. AOI systems make sense for manufacturers who wish to improve the quality of their output while reducing the likelihood of costly faults because of these financial benefits.

Conclusion

Visual analytics of photos and videos used in the production process has many benefits for the manufacturing industry, including increased productivity, accuracy, and consistency, improved production quality control, cost-effectiveness, and a reduction in human error. These benefits make AOI a useful tool for producers looking to uphold high-quality standards, reduce costs, and avoid costly errors and rework.

The importance of automation in visual inspections has increased in the industrial industry as consumer demand for high-quality products and effective production techniques grows. AOI systems help manufacturers satisfy these requirements by providing quick, accurate, and consistent inspection results, reducing the likelihood of human mistakes, and improving product quality control.

In conclusion, enterprises looking to increase production standards cut costs, and raise product quality will find computerised visual inspection systems invaluable. AOI can help you, whether you run a large industrial company or a small business, achieve your goals and stay one step ahead of the competition.

Credits: Vanti

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.