Advanced CMM Programming and Automation Features for Inspection, Reverse Engineering, and Tool Building

At Control, May 9–12, Messe Stuttgart, Germany, Booth 3512, Verisurf Software, Inc. will present advanced CMM programming and automation features included in the soon-to-be-released Verisurf 2024 along with partners IBS Quality GmbH, Blankenhorn GmbH, and Metrology UK Ltd.

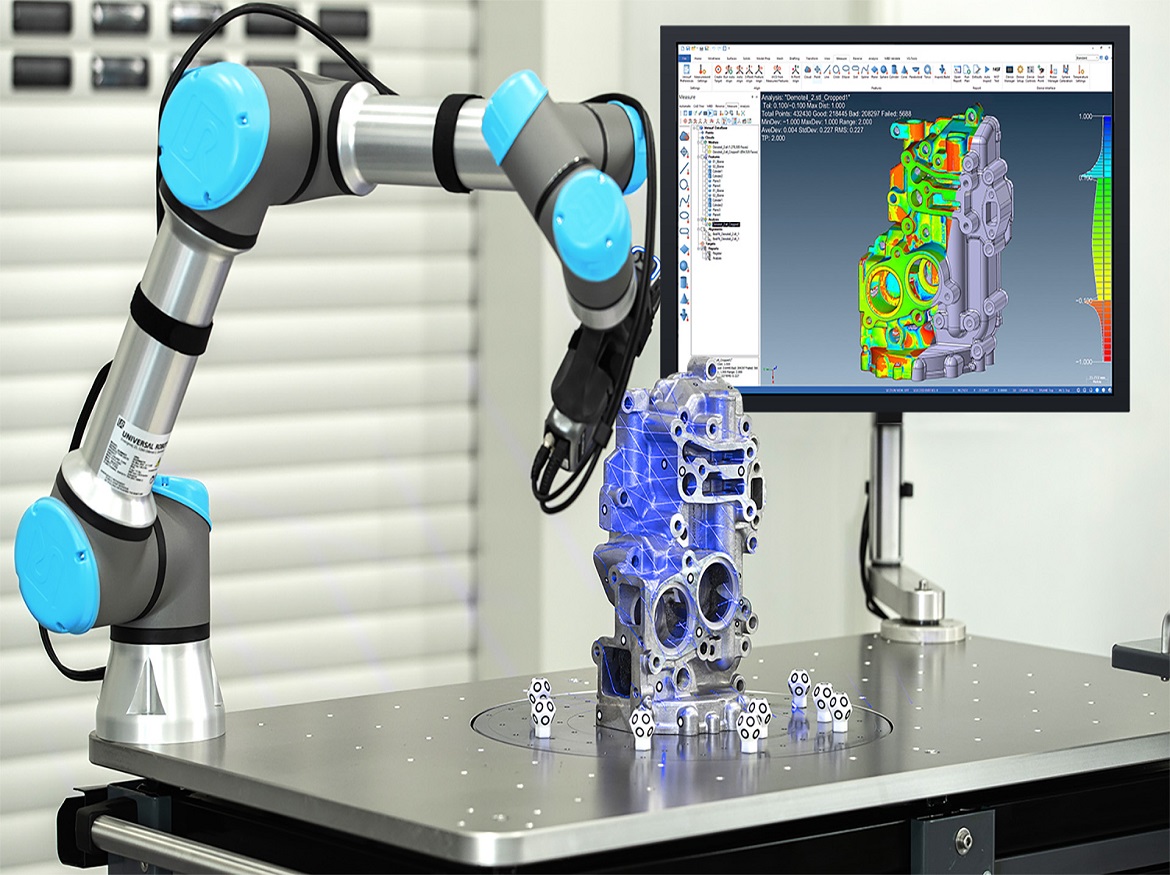

PAM-System, powered by Verisurf, a mobile scanning, measurement, and inspection solution that uses collaborative robots (cobots) to augment repetitive user routines while adding flexibility, dexterity, and accuracy, will be one of many automated measurement and inspection solutions that Verisurf Software will demonstrate at Control.

The most recent version of the well-liked measuring program Verisurf, which is used for automated quality inspection, reporting, scanning, reverse engineering, tool development, and assembly guiding, is version 2024. In the industrial industry, the software is strong, adaptable, and simple to use for measurement applications.

As the only measurement, reverse engineering, and inspection software created on a fully functional 3D CAD/CAM platform with intelligent Model-Based Definition (MBD), Verisurf 2024 builds on the software’s history. This maintains model-based digital continuity while ensuring data integrity and enabling users to carry out metrology processes in a seamless CAD environment. For complete interoperability, Verisurf software works with all CAD file types, and the Verisurf Device Interface (VDI) interacts with and controls all programmable and portable CMMs. By swiftly capturing and processing measurement data for real-world metrology applications with repeatable process control, the software’s modular design enables users to quickly go from reverse engineering to inspection to tool creation across the manufacturing enterprise.

“Verisurf software is always being improved. Every day, we collaborate with customers to find workable solutions to measuring difficulties. Customers receive these improvements all year long as software updates, and we also include them in our yearly version release. According to Nick Merrell, executive vice president of Verisurf Software, Inc., this keeps us in touch with our clients and at the forefront of metrology software development.

Numerous new programming and productivity tools are included in Verisurf 2024 in order to enhance metrology workflows through automation while maintaining repeatable process control. Just three of the things Verisurf 2024 includes are as follows:

New Global Register

Align scan results to nominal reference as soon as possible for automated and manual inspection plans. Between datasets, whether they are cloud to cloud, cloud to mesh, mesh to mesh, or cloud and mesh to CAD, registration is improved.

New Advanced RPS Alignment

The new Automate RPS (Reference Point System) Alignment streamlines the procedure by leveraging points, features, constructs, and surface points to lock in alignment with the CAD model in response to alignment requirements by the automobile sector and others. Advanced control over orientation, rotation, position, weight, and target type is offered by the software.

New Renishaw® REVO Sensor Support

Verisurf is renowned for supporting all Renishaw sensors with a wide range of feature additions. Verisurf 2024 now supports two brand-new REVO sensors.

With an accuracy of.010mm (.0004″), RUP1 (Renishaw Ultrasonic Probe) measures the thickness of ordinary metal parts ranging from 1mm (.039″) to 20mm (.787″).

A range of surfaces, including bores as tiny as 5mm (.196″), are evaluated for surface finish/roughness using the SFP2 (Surface Finish Probe). From the SFP2, Verisurf can gather and report RA, RMS, and unprocessed data.

Verisurf application demonstrations during Control include:

- Robotic 3D scanning and inspection using Verisurf software integrated with the IBS Quality PAM System.

- 5-axis CMM programming, measurement, and quality reporting using Verisurf software with a Coord3 CMM equipped with a Renishaw REVO sensor.

- Automotive body panel scanning and inspection using Verisurf software, and Leica laser tracker with 3D scanner.

- Adaptive scanning and reverse engineering using Verisurf software with a Renishaw EquatorTM automated gauging system.

- 3D scanning for inspection and reverse engineering using Verisurf software with Scantech, and Shining 3D Scanners.

Credits: Verisurf

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.