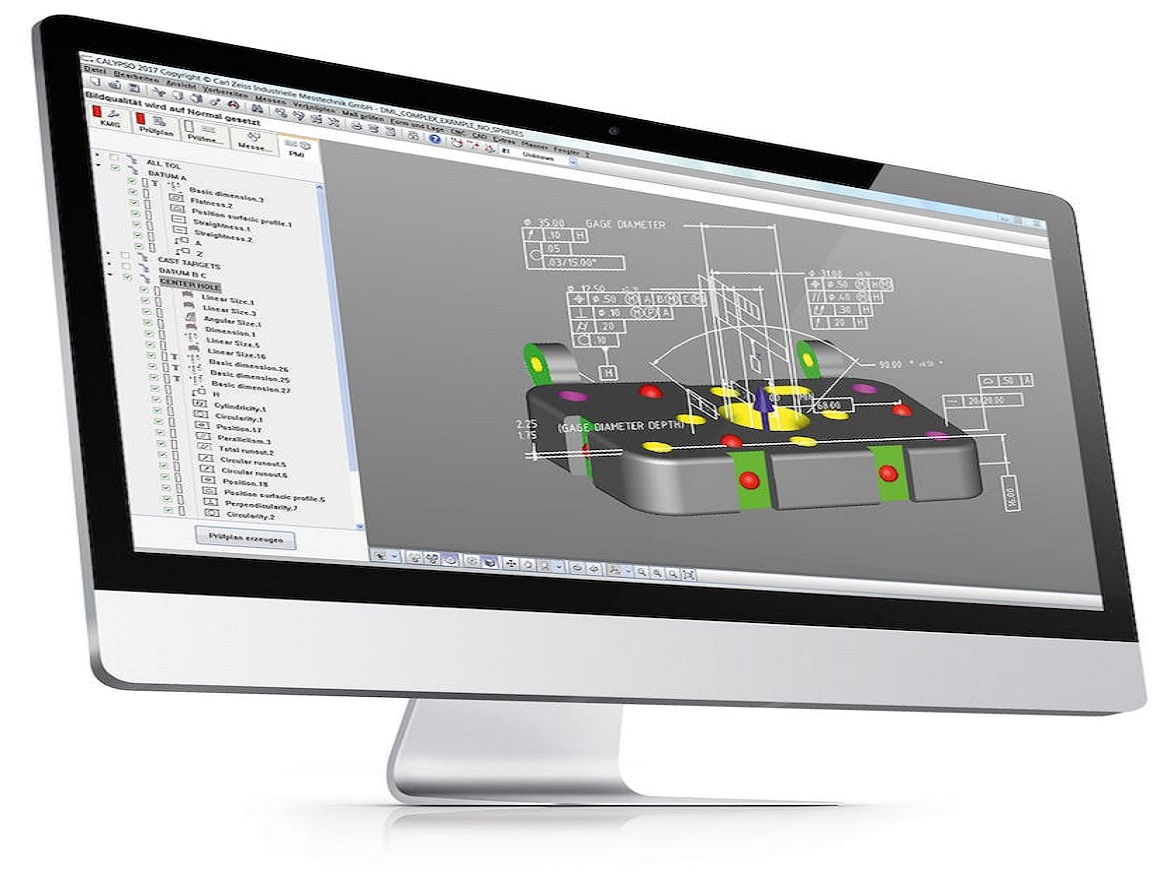

Universal software for dimensional metrology operations

ZEISS CALYPSO

With ZEISS CALYPSO, you’ll measure standard shapes fluently, snappily, and reliably. A single click on the required characteristics is all that’s demanded for programming. In combination with measuring machines and detectors from ZEISS, you admit a high-performance system from a single source. Thanks to a large number of options, ZEISS CALYPSO also offers the right tools for special conditions.

Highlights

- Control of all coordinate measuring machines and detectors from the ZEISS portfolio

- Creation of dimension plans without programming knowledge

- Remote optimization of dimension programs

- Detailed 3D data evaluations and meaningful reports

Technology independence

further inflexibility with lower trouble

In ZEISS CALYPSO, tactile, optic, and multi-sensor match measuring machines as well as roughness detectors from ZEISS can be combined in a dimension plan depending on the asked dimension strategy.

Creation of dimension plans

Simple programming and standardization

With the CAD-grounded metrology software, dimension plans can be created intimately and with just many clicks by using applicable CAD interfaces. The dimensional, form, and position forbearance stored in the CAD model as Product and Manufacturing Information( PMI) are used for this purpose. The ZEISS variable strategy also ensures the community of dimension results.

Automatic generation of trip paths

Ensuring an effective dimension process

The software automatically generates the trip paths between features and contemporaneously optimizes the measuring sequence to reduce operating time. In addition, ZEISS CALYPSO reduces the programming and conservation trouble of dimension plans, as features can be fluently added, deleted, or changed.

Remote dimension plan optimization

ZEISS CALYPSO diary and simulation

With the software options, complete CNC dimension plans can be created and stored on a computer station remote from the machine. In this way, the stoner can pretend the trip paths of the measuring device with ZEISS CALYPSO and perform a collision check in advance. The complete capacity of the dimension device is therefore always retained.

Detailed workpiece evaluation and examination

Analysis of 3D dimension data

druggies can estimate their recorded and digitized 3D data directly with ZEISS CALYPSO. The software supports simple or complex dimension tasks – from mesh processing and CAD import to form and place computations.

Powerful measurement result visualization

ZEISS PiWeb reporting

Professional protocol design is included in ZEISS CALYPSO with ZEISS PiWeb reporting. druggies can profit from protocol templates or produce their own reports and templates to fantasize about dimension results in a meaningful way. With the ZEISS PiWeb reporting plus software option, expansion to statistical functions is possible. In addition, a database for over 1000 data sets is included, and resemblant dimension and evaluation on the match measuring machine is possible as well.

The right tools for special conditions

ZEISS CALYPSO software options

ZEISS offers fresh ZEISS CALYPSO software options for special operations and dimension tasks. You can buy these in addition to the universal ZEISS CALYPSO dimension software to acclimatize the software to your individual dimension conditions.

Examples of ZEISS CALYPSO software options

ZEISS CALYPSO freeform

Software option for measuring, examining, and assaying workpieces with non-standard shapes, and doing 3D face analysis. With the help of CAD models, diversions and dimension results can be displayed graphically on the CAD window.

ZEISS CALYPSO wind

This option can be used to measure and dissect 2D and 3D biographies and to measure multitudinous wind-related characteristics, similar as the following types of angles 2D angles( crossroad on one airplane), 3D angles( crossroad on one cylinder), and stroke angles. Both known and unknown silhouettes can be measured with this option.

ZEISS CALYPSO PCM( Parameter- Enciphered dimension)

This software option significantly decreases the quantum of time demanded to measure corridors in the same part family. PCM is ideal for manufacturers that produce corridors that are analogous in shape, function, and product process, but only differ by many confines.

ZEISS CALYPSO dynamic planning

The software option enables the dynamization of the examination inflexibility. Quality control is therefore optimized for the product. ZEISS CALYPSO dynamic planning generates the sequence of corridors to be audited and adjusts the compass of dimension grounded on rules from MES/ CAQ results or ZEISS PiWeb software.

New norms for further performance and high productivity

Latest ZEISS CALYPSO interpretation

ZEISS CALYPSO has been under nonstop development for 25 times and is thus always at the van of technological progress. These factors are the provocation behind the nonstop enhancement of ZEISS CALYPSO to meet the changing requirements and conditions of druggies.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.