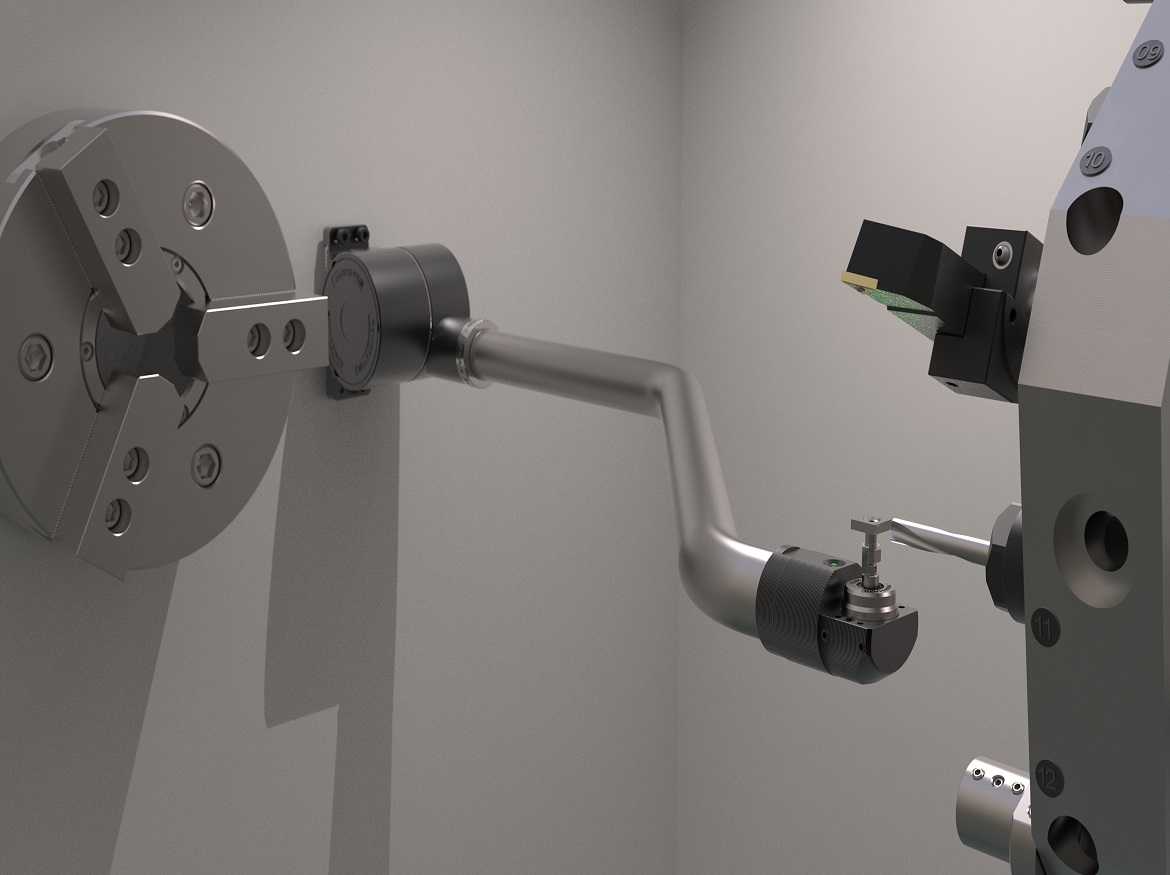

At EMO Hannover 2023, the leading provider of engineering technologies, Renishaw, will display its most recent tool setting arm. The newest member of the company’s series of high-precision tool setting arms, the HPMA-X, was designed to perform in even the most demanding turning applications.

Large CNC lathes can now set tools with high accuracy and identify broken tools thanks to the most recent evolution, which builds on the success of the original high-precision motorized arm (HPMA). This scale of lathe often calls for longer, heavier, and more intricate arm designs, which can be difficult to maneuver smoothly and consistently.

Due to the HPMA-X’s effective and high-performance powertrain, which comprises a digitally controlled brushless motor and high-ratio 3-stage planetary gearhead, such designs are now feasible. This clever mechanism keeps the high torque and strong lift capability while allowing for precise speed control and collision detection.

“Our current HPMA satisfies applications that call for arms up to 555 mm in length. The HPMA-X may be configured in a variety of configurations, up to 1000 mm in length, and is aimed at the expanding market for larger lathes that require arms exceeding 500 mm, according to Steve Petersen, marketing manager for Renishaw’s Machine Tool Products Division. Our experts have worked hard to make sure the probe is introduced into the working environment with outstanding reproducibility on these larger designs, they say.

To maximize the life of the product, it is essential for arms of this size to ensure a smooth transition when the probe is moved into and out of the working area. Smooth motion control is provided by digital control and feedback mechanisms included in the accompanying interface (TSI3-X), which produces predictable acceleration and deceleration characteristics.

Four customer-facing LEDs are also included in the TSI3-X interface for real-time status monitoring. These express any motion or system health issues as well as the status of the input drive instructions, arm confirmation outputs, and drive command status indicators.

“We are seeing an increasing number of manufacturers looking to implement process automation in their factories,” Petersen continues. If you want to stay competitive, you can no longer afford to have machines sit idle while manual tool setting operations are completed. On CNC lathes, the HPMA-X offers automatic tool configuration, and broken tool detection, and can support lights-out manufacture.

Manufacturing is made efficient and sustainable by Renishaw’s precision measurement and process control technologies, such as the HPMA-X. They are able to anticipate, spot, and fix process mistakes before they occur. This contributes to the reduction of scrap and, as a result, the energy, time, and resources lost in generating those scrap components.

Without introducing additional equipment, factory automation boosts total output and machine uptime, which improves operational efficiency. Renishaw probing solutions for CNC machining automation enable enterprises to use their machines more efficiently and run round-the-clock operations.

Physical automation can be achieved thanks to process automation technologies, which boost productivity and, as a result, can use less energy and waste.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.