In the age of Manufacturing 4.0 and digital transformation, the manufacturing sector is undergoing a paradigm shift. What started out as a simple trend is now an essential industrial requirement.

One of the most encouraging headways is shut circle producing, helped by the computerized unrest that has made ready for groundbreaking progressions in the assembling business. Shut circle fabricating stands apart as an earth-shattering idea that boosts efficiency and quality via flawlessly incorporating input metrology information by interconnecting designing and assembling together. I would like to discuss the benefits of closed-loop manufacturing in this LinkedIn blog post, highlighting Sandvik’s crucial role in propelling the industry forward with its expertise in digitalization, tooling, and cutting-edge solutions. Sandvik’s brand-new digital manufacturing strategy is uniquely positioned to assist you in your digital transformation journey.

Closed-loop manufacturing: revolutionizing production efficiency

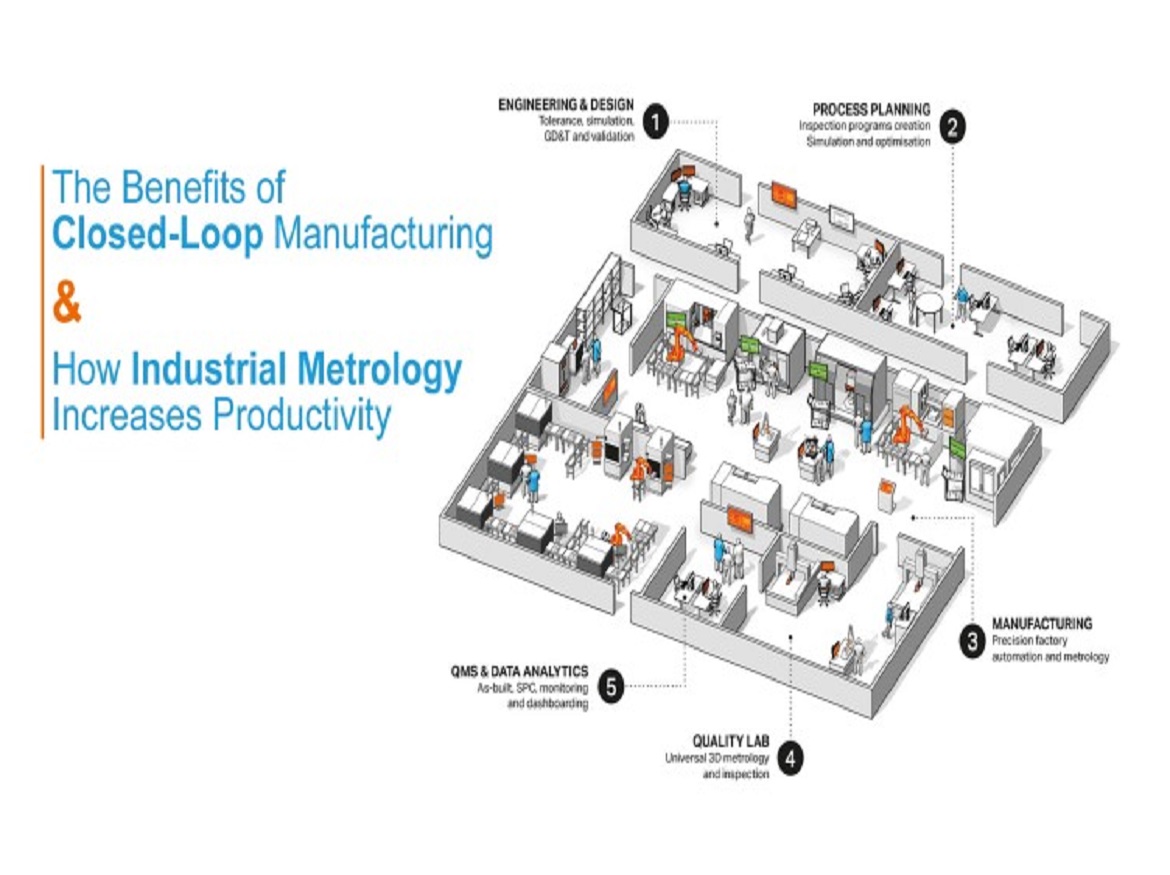

Shut circle fabricating spins around the consistent input circle between the assembling system and metrology information. You can gain invaluable insights that enable you to fine-tune your processes for maximum efficiency by collecting and analyzing real-time data from various stages of production. Your team will be able to quickly identify and resolve issues thanks to this integration of feedback data, resulting in increased productivity and decreased downtime. When properly interconnected, your Industrial Metrology solutions become your production floor’s eyes and ears. After that, it becomes simple to define an automated procedure that can be executed in real-time to boost manufacturing output.

Sandvik’s leadership in closed-loop manufacturing

Sandvik, a market leader in manufacturing, plays a crucial role in making closed-loop manufacturing possible. Sandvik offers comprehensive solutions to help businesses make use of the power of metrology data because it has a thorough comprehension of tool expertise, manufacturing procedures, and digitalization. Sandvik is prepared to assist the manufacturing sector in effectively collecting, analyzing, and utilizing pertinent data feedback through their cutting-edge digital offerings, which include CAM and metrology. Engineers get a lot out of using feedback metrology data, and manufacturers can use this data to quickly identify variations, deviations, and potential quality issues. Therefore, this enables you to go with informed choices, change boundaries, and streamline processes for further developed item quality. Additionally, you can use predictive maintenance strategies to minimize machine downtime and increase productivity by analyzing data trends over time.

Understanding all of this data is all that is required to make it happen: This mostly depends on having relevant data, understanding how to extract meaning from it, connecting all of this information to your digital/manufacturing flow, and possibly automating some of it.

Working towards a more efficient and sustainable manufacturing world

This collaboration with Sandvik’s mechanical arrangements, a specialist in assembling processes for over 160 years, conveys a bunch of basic arrangements you can expand upon to give constant improvement and streamline your shop floor.

“… closed-loop manufacturing is a game-changer for the manufacturing industry. You cannot ignore it any longer.”

Closed-loop manufacturing is a game-changer for the manufacturing sector because it uses feedback metrology data. You can’t continue to ignore it. In this transformative journey, Sandvik’s dedication to innovation and expertise in connecting manufacturing and digitalization solutions are crucial. By embracing shut circle assembling and utilizing Sandvik’s answers in CAM, Modern Metrology, Computerization, and Designing/SPC, you can undoubtedly open new degrees of efficiency and quality.

They want you to learn more about their Industrial Metrology solutions by going to the Sandvik Manufacturing Solutions website. There, you can read a more in-depth article about how the interconnected solutions can also help you along this path:

Choose the company you are most interested in learning more about if you want to learn more about Sandvik Industrial Metrology Solutions and its businesses. It is most likely currently coordinated with your machines and furthermore completely viable along with your current computerized stream:

- To find the world-driving and the most flexible 3D Modern Metrology programming: LinkedIn profile or the Metrologic Group’s website.

- To learn more on GD&T Recreation, stack-up examination, and furthermore measurable, SPC, and dashboarding: LinkedIn profile or the Dimensional Control Systems website.

- To learn more about robotization and full in-line and at-line Computerized noncontact super-quick with the Up and coming Age of Estimating Machines and mechanized frameworks: DWFritz Automation’s website or LinkedIn page.

- You can also check out the Sandvik Manufacturing Solutions LinkedIn page to learn more about our digital suite of tools that are geared toward CAM and ready for the shop floor.

Finally, they provide you with an invitation to look around the Sandvik Manufacturing Solutions website. It will give you an extra profundity into our assembling and computerized reconciliations where large information can be saddled and quickly dissected with a dash of man-made intelligence drawing you nearer to “shrewd assembling”. This is what you get every day in every workshop from Sandvik’s digital solutions and expertise in industrial manufacturing. Not only are we still quite far along this journey, but we are also a reputable industrial player who has utilized this strategy and our tools for a considerable amount of time.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.