Incoming Material Inspection is a critical quality control step in production. By pre-checking raw materials and components, we ensure they fully comply with regulations and standards before entering the assembly line. Strict quality control at this initial stage can effectively prevent assembly failures and product defects caused by poor materials, thereby improving production efficiency and maximizing capacity utilization.

Driven by continuous technological upgrades and accelerated product innovation, companies are experiencing growing shipment volumes. This places higher demands on the incoming inspection department—they must ensure inspection quality while increasing inspection speed to provide early assurance for subsequent production.

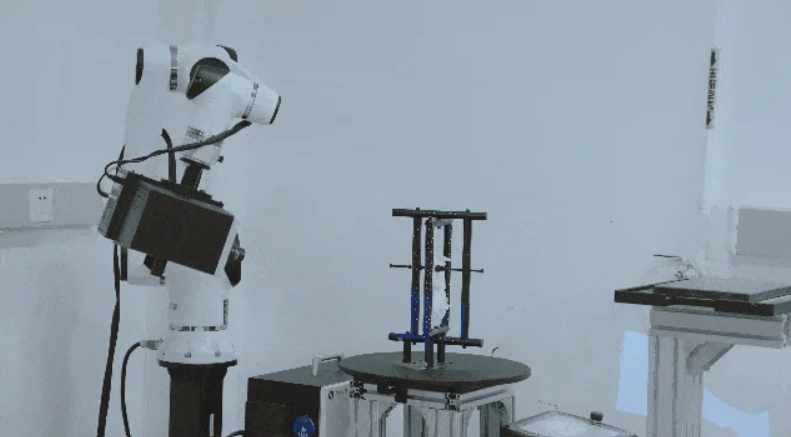

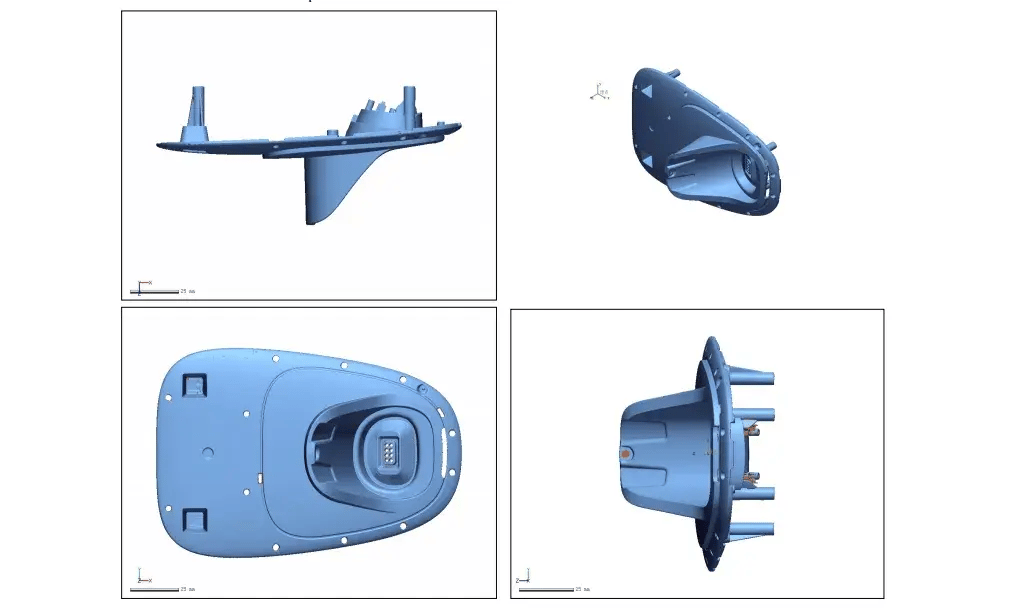

In SHINING 3D’s incoming material inspection room, the company independently develops an automated 3D scanning inspection system. This system is designed to efficiently handle diverse types of parts and large-scale dimension inspection tasks. It integrates a high-accuracy metrology 3D scanner, a collaborative robot, and other hardware. It seamlessly connects with 3D scanning and inspection software to build an automated workflow that covers equipment calibration, high-accuracy 3D scanning, data analysis, and full-size inspection.

Advantages of SHINING 3D’s Automated Inspection System

Automated Scanning

By mounting a high-accuracy metrology 3D scanner on a collaborative robot, the system can automatically follow a preset scanning path to obtain full-size 3D data of components with just one programming setup. Automated operation reduces human intervention, ensuring consistency and repeatability in dimension inspection while significantly shortening inspection time and facilitating subsequent production.

High Versatility

The high-accuracy metrology 3D scanner is highly versatile. It can meet various dimension inspection needs, ensuring accurate measurement from basic parts to complex structures. Companies don’t need to customize dedicated inspection fixtures and tools for each part or product line.

Accuracy Assurance

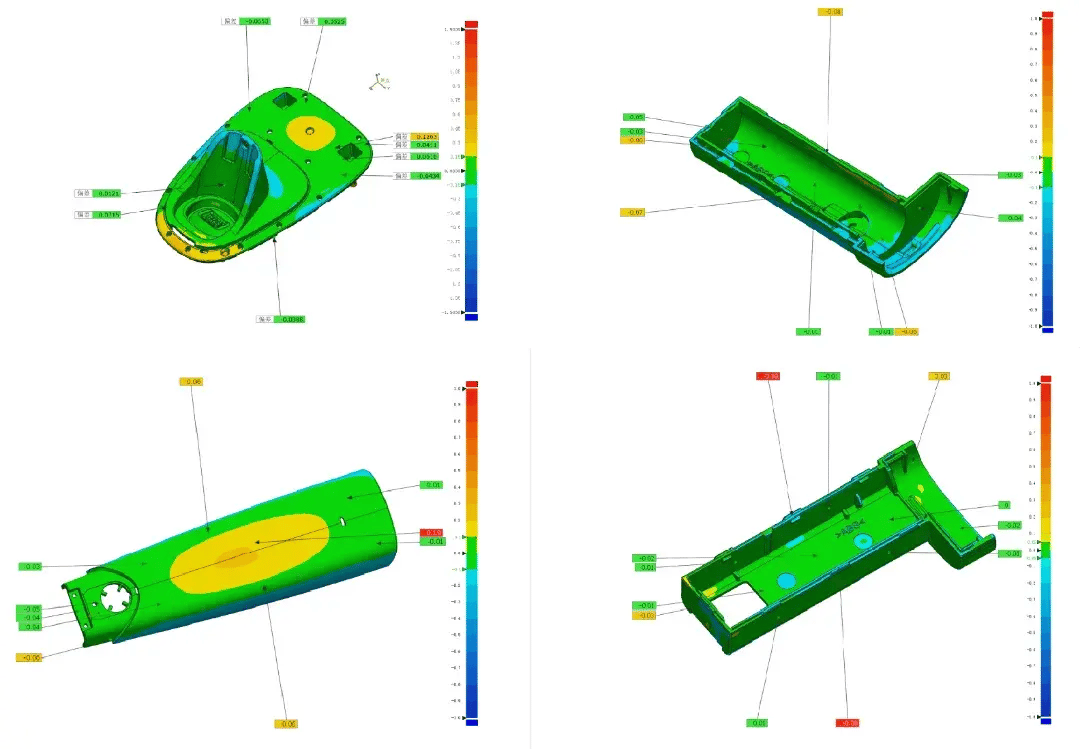

SHINING 3D’s OptimScan 5M Plus provides core technical support for this automated inspection system. OptimScan 5M Plus has an accuracy of 0.005 mm and a point distance of 0.04 mm. It can easily capture complete data of complex details like tiny holes and deep grooves.

Data Traceability

The high-accuracy data obtained through 3D scanning lays the foundation for building a fully digital inspection system. Throughout the entire production chain—from mold design and mass production of parts to finished product inspection—the data from 3D scanning can be seamlessly imported into the company’s quality management information system. This achieves traceable quality records.

Conclusion

SHINING 3D’s automated inspection system offers a powerful solution for modern manufacturers facing increasing inspection challenges. By combining high-accuracy scanning, automation, and data traceability, this system not only ensures that incoming materials meet the highest standards but also significantly improves production efficiency. As manufacturing continues to evolve, adopting advanced technologies like this will be crucial for maintaining quality and staying competitive in a rapidly changing industry.