Specifically for transmitted light and multi-sensor measuring devices, Witte has recently developed a combination measurement system that promises to significantly boost flexibility, speed, and convenience in daily use.

The exceptionally user-friendly spring mechanism for holding and securing measurement-related components lies at the heart of the invention. Without the use of any tools, centering cones can adjust to different diameters and even hollow objects like pipes. Optional versions enable the integration with additional components, such as a rotating and staked-out ALUFIX hand chuck. Even heavier workpieces are kept securely in place by the spring force, which is adjustable from 26 to 36 newtons.

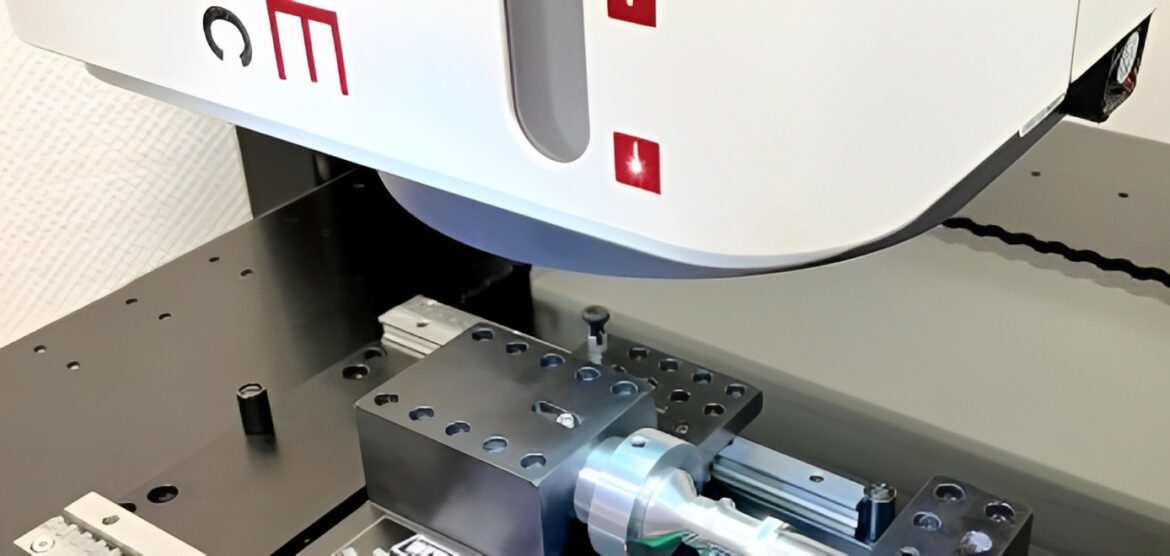

The new 160 mm combination measuring fixture’s adjustable range allows objects with component lengths as long as 145 mm to be accommodated. The slide, which can be moved and secured by locking bolts via pawl rails and linear guides, is used to modify the workpiece length very conveniently.

The combination measuring fixture, which is a part of Witte’s modular clamping system ALUFIX, includes system holes that are compatible with the ALUFIX size AF16. The building of the corresponding measuring table is also made possible by a particular connection hole pattern.

ALUFIX-realized devices and measurement settings are consistently reproducible. Almost all of the basic components put in fixtures can be used endlessly and repeatedly over an extended period of time thanks to the modular system’s consistent implementation.

Credits: Witte Barskamp

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.