The article has been originally written by George Schuetz. It is being reproduced here.

Air gaging has always proven to be an excellent choice for fast, easy-to-use and reliable, high performance dimensional gaging.

Air gaging has always proven to be an excellent choice for fast, easy-to-use and reliable, high performance dimensional gaging. But did you ever think it could be used to check those Styrofoam end caps that secure your new gaming system in its shipping container? Well, it can, and it does it very well.

Styrofoam, or expanded polystyrene (EPS), is a basic term for styrene polymers that can be expanded into a multitude of different products. EPS has been available for more than 50 years and proven in numerous packaging applications. It is ideal for packaging and shipping applications because of its strength, light weight, cushioning characteristics, dimensional stability, and the fact that it is thermal and moisture-resistant.

EPS is supplied to molders in the form of polystyrene beads that are loaded with a blowing agent, usually pentane, and other agents that give the beads the ability to expand and be molded into low-density foam products. In the end, EPS is 90% air – which accounts for its light weight. By varying the mixture of chemicals and the heating process, the foam characteristics can be changed to vary the density and create the best mix for the specific packaging requirement.

So what does this have to do with air gaging? Because the density can be varied to change the characteristics of the material, the end product then has to be checked to make sure it will perform under load. You have probably noticed differences in some of the Styrofoam products that came with your Blu-ray player or new computer: some are rock hard, while others may be a little “crumbly” and break apart easily. What is at work here is the bonding agent in the foam. Regardless of the desired density, if the bonding agent has been used successfully, the beads will all be held very tightly together. If not, they will tend to break apart – not only in your hand, but during the transport of your precious new toy. Bonding removes air between the beads and seals the matrix.

This is where the air gaging comes in. The less air between the beads, the stronger the bond. The more air, the weaker the bond. And if there is air between the beads, there is also a path for air to flow through. By applying pressurized air to the Styrofoam, we can monitor the flow of air through the material. It’s like using air to measure little bitty holes, but in this case we are measuring a lot of itty-bitty holes. Just as we used the air gage as a flow meter for small holes, we can do the same for this material.

In the application, an open-air probe is pushed into the Styrofoam part. A stop collar on the end of the probe limits the probe travel into the part and also acts to seal off any air escaping from the hole. If the bonding of the beads is good, there will be virtually no place for the air to go, which presents high back pressure to the air gage. If the bonding is not so good, there will be gaps between the beads allowing the air to flow through, resulting in less back pressure.

Just as with previous flow gage examples, we need a set of reference standards to set up the low end of acceptability. The gage is then set up with these standards to create the limits. Now it’s pretty easy for the operator to use: he brings a part to the gage, sticks in the air probe and observes the scale. Limit lights can also be used to set the acceptable limits.

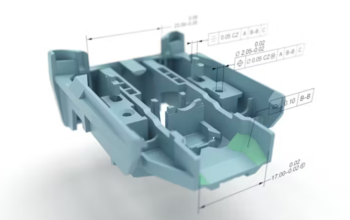

Another characteristic of EPS is how well it flows through the mold and matches up to the molding surface. If the flow is correct, it will follow exactly the surface of the mold. If the mold has a flat surface, the part will be flat. Should the flow not be correct, the beads will not completely form the surface and the end result would be a slightly bumpy surface that could easily break off and get into the shipment. Again, air gaging can be used to check this by manufacturing an open-air jet probe with a large flat surface, which is laid on the surface of the part. If the surface is smooth, the probe will seal nicely with the part. If the process was not quite right, gaps will exist, allowing air to escape. Both cases represent changes in back pressure that the gage can measure and display