The entire 3D measurement process at a glance: Spray, Program, Scan, Evaluate.

The individual steps along the 3D scanning process will be demonstrated live at Formnext by AESUB Scanningspray, ElvenDynamics, IBS and Verisurf in real application. From surface preparation, programming the measurement robot, optical automated measurement and finally evaluation and documentation of the scan results will be presented in a seamless sequence. The interaction of the individual steps makes the complex process a straightforward operation.

The 3D measuring process

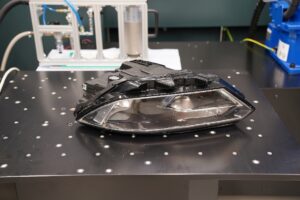

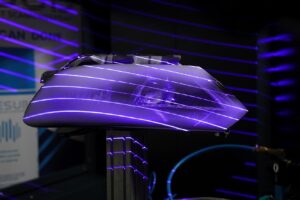

Matting of the components

Most optical scanners have difficulties in capturing glossy or transparent surfaces. Therefore, the parts are first matted with the AESUB scanning spray. The process takes only a few seconds. A thin, white homogeneous coating is applied with allows to optically measure the part. The AESUB spray evaporates completely after application, so that neither the component nor the environment need to be cleaned. AESUB sprays are free of pigments and titanium dioxide, which is hazardous to health.

Programming the robot

The Nexos 4.0 software from ElvenDynamics is used to program the measuring robot for automated measurement. With just a few steps, the measurement environment is simulated. Afterwards, the user can automatically generate optimized measurement routines.

Measurement of the component

The optical measurement is then performed with the automated and mobile 3D measuring system PAM (Portable Automated Measuring) from the IBS Quality. PAM connects hardware and software to form a user-friendly scanning and inspection system.

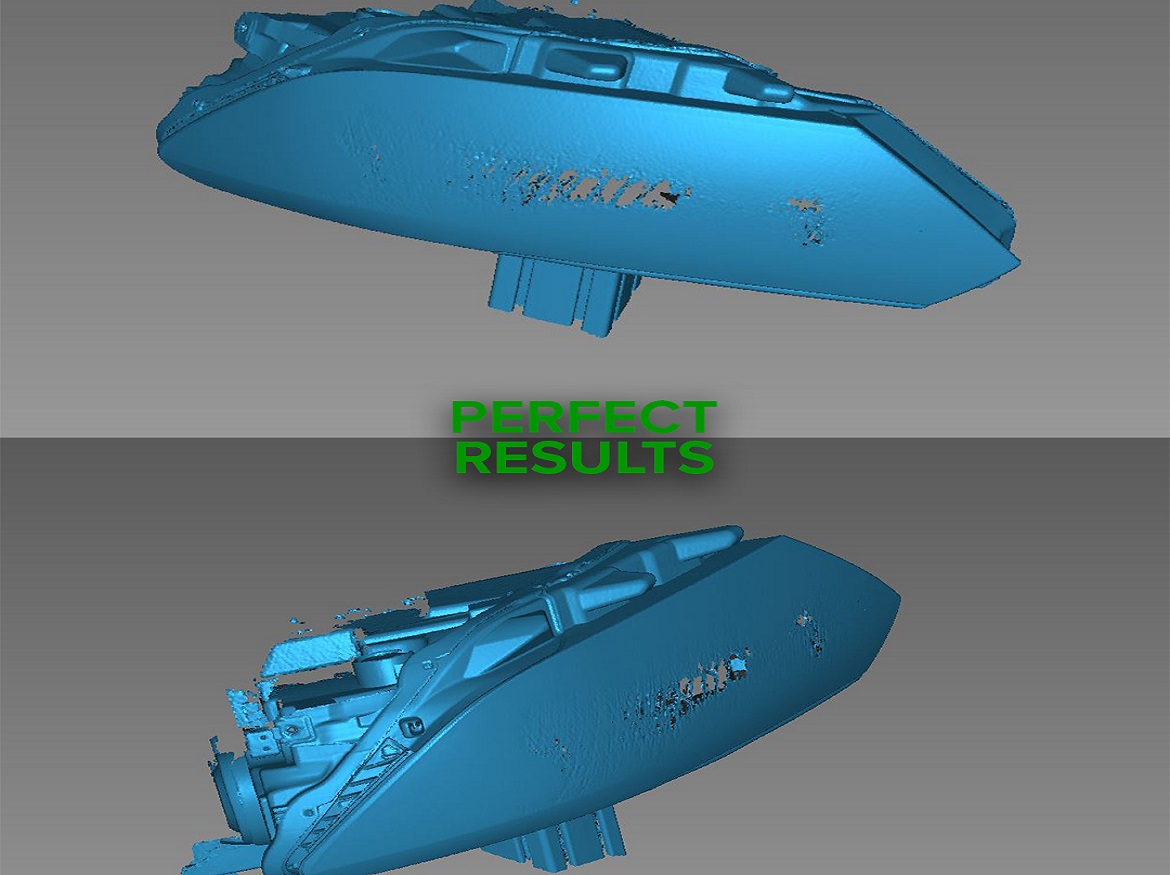

Evaluation of the data

The acquired data is evaluated with the Verisurf software. Verisurf software can be used to solve general as well as application-specific measurement tasks. Verisurf’s unique, CAD-based architecture can read any file format, interoperate with any common, portable CMM (including arms, trackers, and scanning systems) and has the most flexible reporting capabilities available.

“With the live demonstration, we want to show how the individual products merge into an integrated solution and how the measurement process, which is complex in itself, becomes an easy-to-perform application,” explains Prof. Dr. Sebastian Gell, Co-Founder of Scanningspray Vertriebs GmbH.

Formnext Hall 12.1, Booth D40

At Formnext, a live demonstration will show how scanning spray, software and measuring robot merge into an integrated solution and turn complex measuring process into an easy-to-perform application.