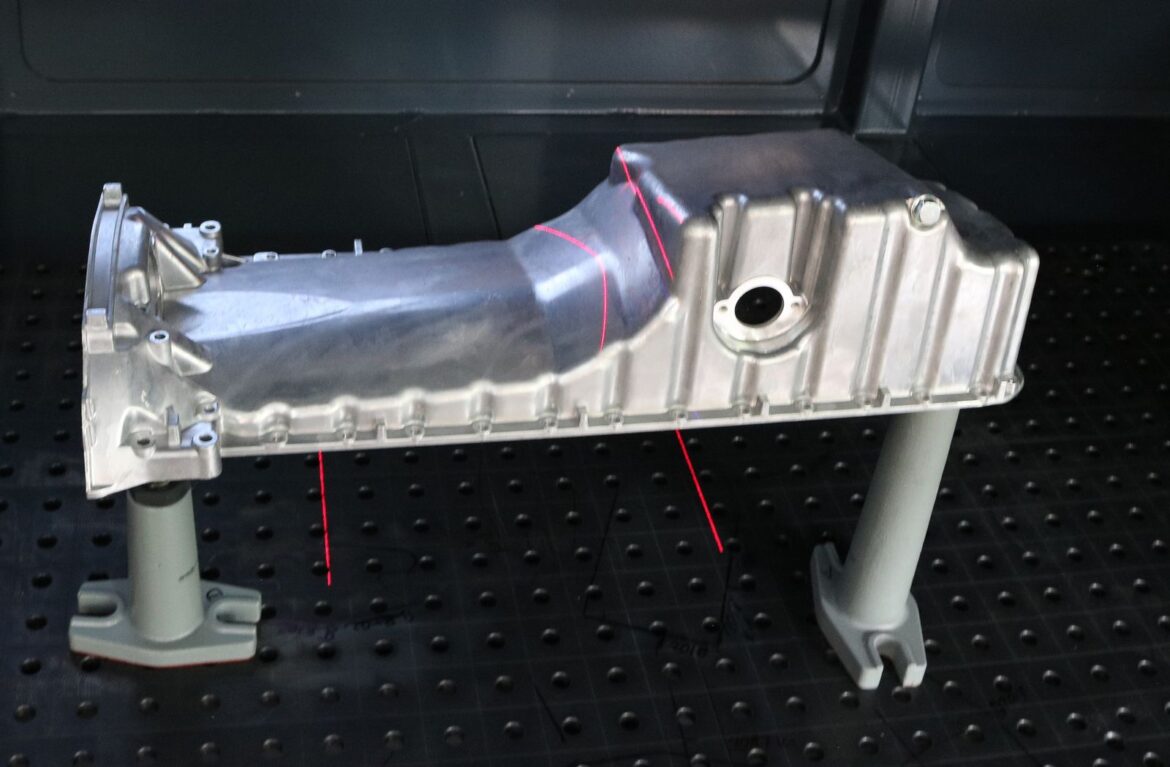

Introduction: Quality assurance in the automotive industry is crucial, with little room for error. Ensuring that large assemblies, such as oil pans and other aluminum or sheet metal components, meet exact specifications is a challenging task. This case study explores how the ZScan® 3D multi-sensor system from senswork addresses these challenges by providing accurate, three-dimensional measurements and comparisons against CAD data.

Challenge: The primary challenge was to perform 3D measurements on large assemblies made of aluminum, such as oil pans, without any shading effects that could compromise accuracy. The automotive industry requires not only the detection of form deviations but also the identification of subtle defects, including air bubbles and blisters, which can affect the integrity of automotive parts.

Solution: The ZScan® 3D multi-sensor system from senswork, utilizing laser triangulation, was implemented to address these needs. This advanced system was selected for its ability to provide high-resolution, three-dimensional measurements of large assemblies. The system operates within the production cycle, allowing for real-time quality control.

Key Tasks:

- 3D Measurement and CAD Comparison: The system was tasked with performing 3D measurements of large aluminum assemblies, ensuring they align precisely with their CAD models.

- Defect Detection: The ZScan® system identified three-dimensional defects, such as air bubbles and blisters, on automotive body-in-white parts.

- Form Deviation Analysis: It also determined any form deviations that could affect the part’s performance or fit.

Benefits: