Global 3D scanning hardware and software leader Artec 3D has unveiled its first target-based laser scanner as part of plans to expand further into industrial metrology.

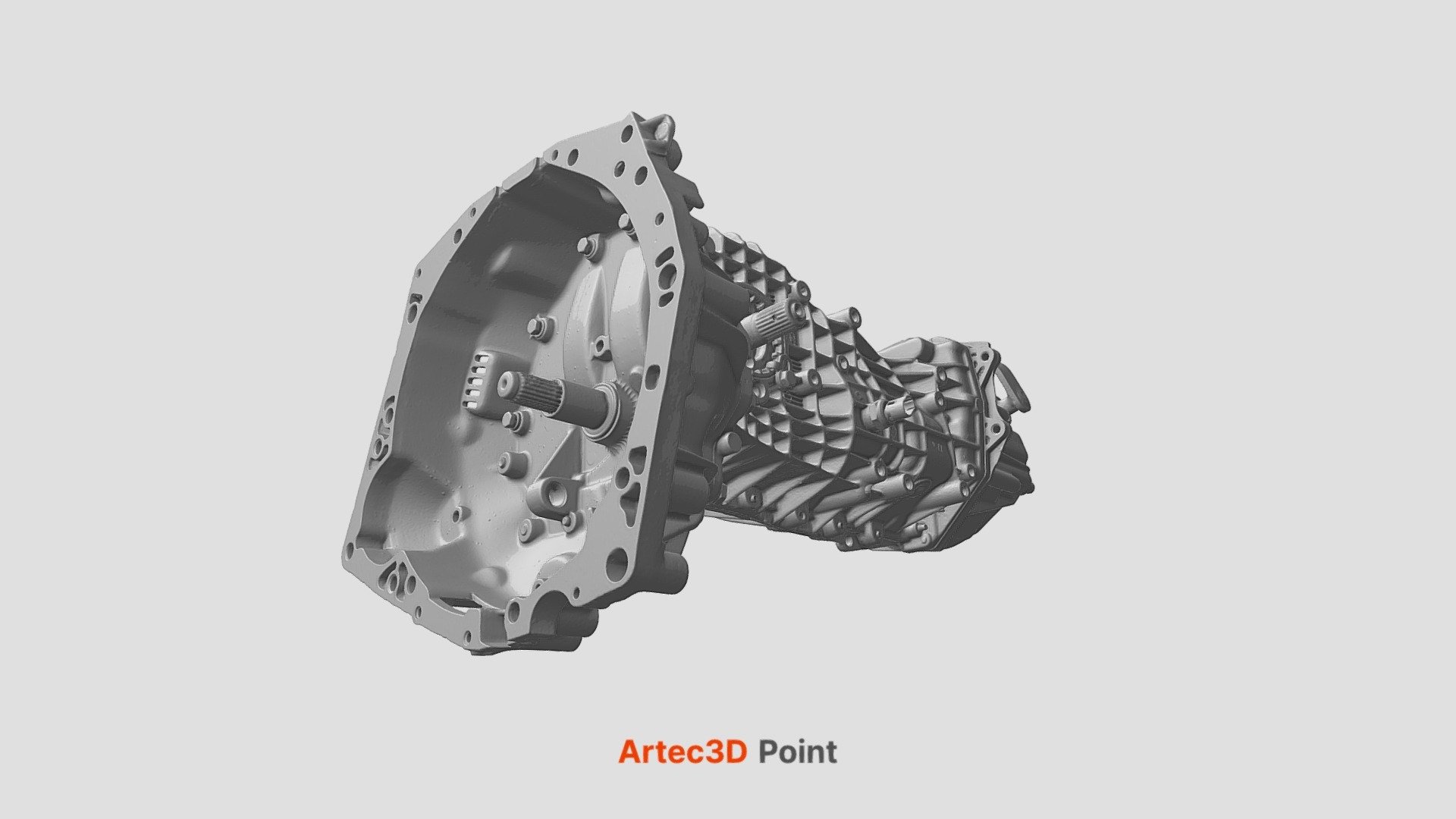

While Artec 3D scanners already offer rapid, accurate, precise data capture to users across industries, the company has now introduced a dedicated metrology solution. Accurate down to mere hundredths of a millimeter, Artec Point consistently captures the high-quality data needed for reverse engineering, quality inspection, and other demanding metrology tasks.

“Our scanners have been making inroads in the field of industrial metrology for years. So it only makes sense to launch a solution that caters precisely to these users’ needs,” said Art Yukhin, CEO and President of Artec 3D. “With metrology-grade accuracy, high repeatability, and long-lasting durability, Artec Point offers a purpose-built industrial solution. We are excited to broaden our offering to customers operating in the metrology space.”

Built for industrial metrology

Verified in an ISO-certified lab against VDI/VDE 2634 & JJF 1951 standards, Artec Point’s outstanding 0.02 mm accuracy and precision put metrology-grade 3D scanning in the palms of users’ hands. The device captures objects of different size, finish, and intricacy, including dark, shiny surfaces and deep holes, at speeds up to 120 FPS or 2.8 million measurements/s.

Thanks to its robust metal casing, Artec Point withstands challenging industrial conditions, while its ergonomic grip and lightweight chassis make it easy to maneuver into tight spaces for measuring difficult-to-access areas.

Standing alongside Artec 3D’s existing metrology offering, which ranges from the desktop Micro II to the LiDAR Ray II, Artec Point broadens Artec 3D scanning’s reach into new applications in sectors such as automotive, aerospace, manufacturing, and heavy industry.

Artec Point: a unique proposition

Artec Point also features full integration with Artec Studio: a powerful, yet easy-to-grasp 3D scanning software. This allows the device to be easily paired with other Artec 3D scanners to develop novel solutions to complex tasks.

Artec Studio is also packed with algorithms that streamline data processing, while Artec Point’s intuitive UI enables operators to achieve repeatable capture results, regardless of skill level.

An essential tool for reverse engineering and quality inspection, Artec Point’s usability and consistency lend it a unique value proposition, currently missing from the metrology space.

“In a crowded metrology market, where many scanners offer similar levels of accuracy, Artec Point distinguishes itself with an unmatched combination of precision, intuitiveness, and software integration,” adds Art Yukhin, CEO and President of Artec 3D. “With the Artec Studio-powered Artec Point, users can easily achieve accurate results, every time – making it a standout choice for applications like reverse engineering and quality inspection.”

Artec Point & Spider II: A joint launch

Alongside Artec Point, Artec 3D has also introduced another handheld 3D scanner: Artec Spider II. Capable of capturing ultra-high-resolution, highly textured scans of small-to-medium objects with steadfast accuracy, the device is perfect for use cases where fine detail is key.

With these launches, the company has further underlined its commitment to 3D scanning excellence, innovation, and addressing the needs across industries with a full range of solutions that meet users’ specific application requirements.