High-accuracy scanning instruments that produce incredibly precise 3D models and guarantee the best input data for your additive manufacturing processes.

3D scanning for additive manufacturing

Benefits

9x

faster than a CMM

Capture up to 35 million points in 1 second, compared to the hours needed by a CMM to capture a few hundred.

0.01 mm

max accuracy

Our 3D scanners are remarkably simple to use while meeting tolerance benchmarks well below 1 mm even without targets – our desktop 3D scanner achieves as high as 10-micron accuracy.

<2h

for training

With Artec solutions, ease of use and convenience are front and center. You’ll be confidently scanning in under 2 hours!

0

contact

With no targets or reference spheres needed, you can capture sensitive, fragile, or unwieldy items without having to handle them.

Applications

Prototyping

Speed up prototyping and quickly actualize design concepts using our 3D scanners to create high-resolution models that you can 3D print and test.

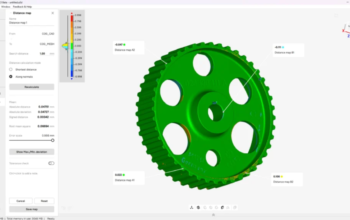

Inspection and quality control

Optimize your QC process by quickly scanning your 3D-printed objects, and use the resultant high-accuracy, high-resolution 3D models to compare printed objects to your original designs.

Reverse engineering

This process has never been easier as you capture existing parts with Artec 3D’s high-resolution scanners and use Artec Studio to seamlessly go from 3D scan data to editable CAD models that you can 3D print.

Custom parts

With 3D scanning and additive manufacturing, custom parts, legacy parts no longer being made, or broken parts that cannot be repaired or replaced have new hope of completing the picture.

Varied materials

Parts can be made in a variety of materials, allowing the creation of parts that are more durable, flexible, or otherwise suitable.

Medical innovation

From prostheses to organs to medical equipment, the medical industry undoubtedly benefits from the varied possibilities that additive manufacturing represents.