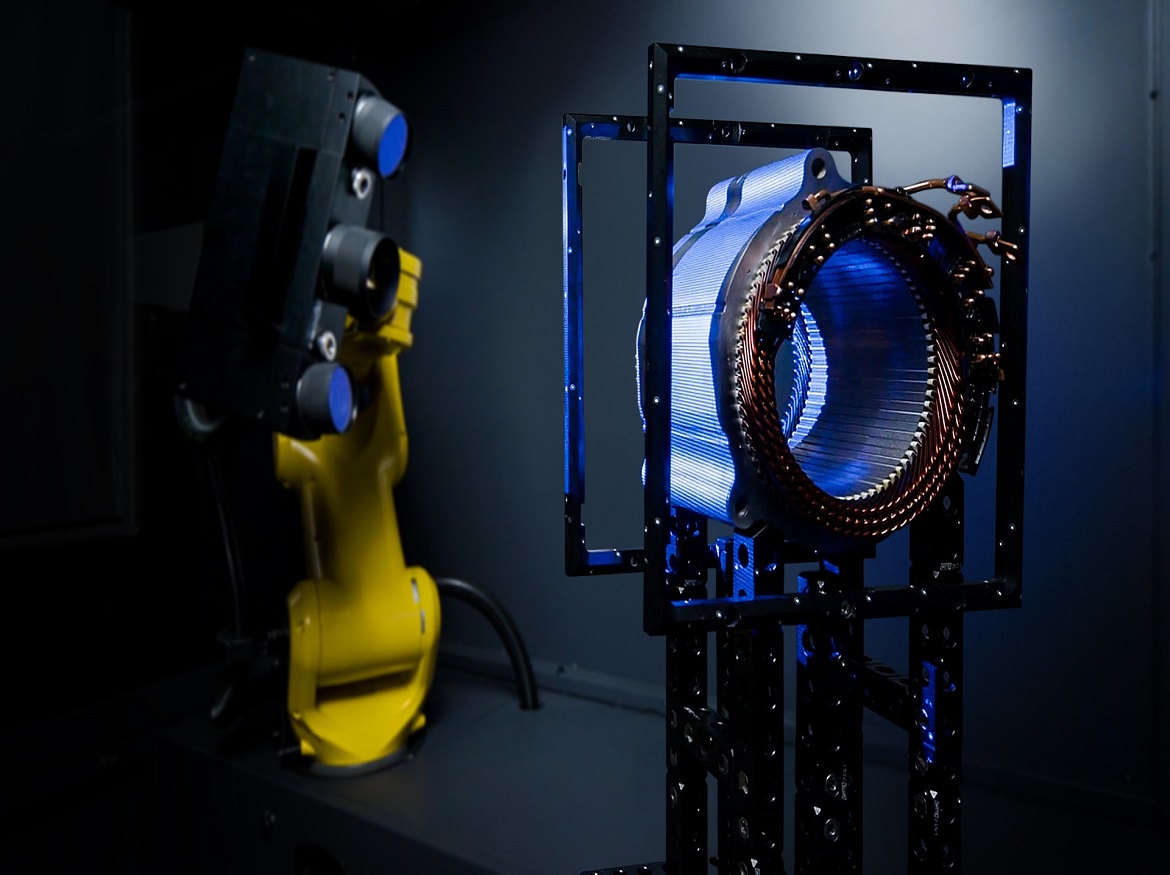

ZEISS ScanBox for eMotors

The highly quick and accurate inspection and digitalization of stators and hairpins is a specialty of the ZEISS ScanBox for eMotors. In a very short period of time, both complete stators with the hairpins and single or numerous hairpins can be totally automatedly inspected. The robust inspection software included in the ZEISS Quality Suite is used to visualize and analyze the 3D measurement data that have been acquired.

Optical 3D Measurement Technology: Fast, Precise, and Reproducible Measuring Results

The automated ZEISS ScanBox for eMotors includes a ZEISS ATOS Q sensor. The ZEISS ATOS Q captures high-quality information in a little amount of time, providing a solid foundation for further evaluation. Even for structures that are touch-sensitive, ATOS Q’s non-contact fringe projection technology enables precise and repeatable acquisition of measurement points.

Full Surface Digitization

For full-surface, automated scanning of single or numerous hairpins as well as full stators, the ZEISS ScanBox for eMotors was created. No prior surface preparation is required.

Digital Geometrical Twin

The software uses 3D coordinates that are dispersed over a large area to create a complete geometrical digital twin. In comparison to the CAD model, this makes it possible to rapidly and accurately identify deviations and flaws in component geometries.

Easy Operation

Through a user-friendly software interface called the Kiosk Interface, you can configure and manage ZEISS ScanBox for eMotors. Press the start button after inserting the component and choosing the measuring program.

All-in-One Software for the Entire Workflow

The inspection software included in the ZEISS Quality Suite is used to operate the ZEISS ScanBox for eMotors, including data collecting, inspection, and reporting. Simple and sophisticated inspection duties, ranging from individual measurements to monitoring in series production, can be included in the measurement workflow. The user-friendly user interface, the kiosk interface, and the virtual measurement room (VMR) are used to carry out measurement and inspection sequences. Tolerances for shape, angle, and location as well as bending points, radii, and leg lengths are frequently analyzed for hairpin quality control.

Virtual Measuring Room

The inspection software included in the ZEISS Quality Suite is used to operate the ZEISS ScanBox for eMotors, including data collecting, inspection, and reporting. Simple and sophisticated inspection duties, ranging from individual measurements to monitoring in series production, can be included in the measurement workflow. The user-friendly user interface, the kiosk interface, and the virtual measurement room (VMR) are used to carry out measurement and inspection sequences. Tolerances for shape, angle, and location as well as bending points, radii, and leg lengths are frequently analyzed for hairpin quality control.

Inspection of Stators and Hairpins

The nominal data from the CAD model can be compared to the actual data once the digital geometric twin has been produced. The two data sets are aligned with one another for this purpose, for as by using the inner cylinder of a sheet metal package, a face, a notch, or a connecting hole. Different quality parameters can be checked by comparing surfaces. The focus of the hairpin inspection is on characteristics like deformations at the hairpin ends or the bending and folding process, whereas the inspection of a stator includes checking for cracks, deformations of the winding cage or the connection points, deflections, displacements, and the roundness of the inner cylinder.

Trend Analysis

Automatic trend analysis makes it possible to spot deviations from the ideal model early on. Continuous measurements enable the prompt detection of changes in earlier manufacturing phases. This allows for the derivation of necessary changes that may then be applied to earlier production phases.

Digital Assembly

In an electric motor, the stator and the rotor must be perfectly aligned. Digital assembly can be used to simulate and check this in advance. It seeks to assess how accurately the components fit together.

Technical Information

Dimensions: 1600 × 1200 × 2100 mm

Power supply: Standard, 100 – 240 V (1-phase, 16 A)

Max. part size: Ø 500 mm

Max. part weight: 100 kg

Entry: Sliding door with safety lock

Opening width: 685 mm

Floor mounting or fixing: Not required, mobile

Loading concept: Manual, crane

Sensor compatibility: ATOS Q for eMotors

Unique Interaction of Optical 3D and Tactile Measurement Technology

When doing a metrological inspection of electric motors, ZEISS PRISMO is the perfect addition to the ZEISS ScanBox for eMotors. This coordinates measuring equipment is ideal for measuring very small tolerances and offers accurate measurement information even for challenging-to-access features.

ZEISS eMobility Solutions

Software and technical implementation are all provided by the same source: The best method for assuring process reliability in the manufacturing and assembly of stators and hairpins for electric motors is the integration of optical 3D metrology with high-precision tactile technologies.

Automation with ZEISS Integration Series

Throughout the whole measuring process, ZEISS feeding and loading systems optimize the flow of parts and operation times. This holds true for the integration of tactile metrology and optical 3D metrology in the measuring room as well as near or on the manufacturing line.

One Point of Contact for Your eMobility Project

Trust ZEISS for your unique project, and speak with our New Energy Vehicles specialists. Put your faith in our extensive experience implementing national and international projects, as well as our expertise in industrial measurement technology. Your neighborhood partner is available for you, from planning to servicing.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.