When customers enquired, Mahr replied: For the purpose of automating recurring measurements, Mahr Engineered Solutions (MES) has created a practical solution. Without an operator, a collaborative robot loads measurement stations in the measuring room or next to the production line, greatly increasing the rate of utilisation of the measuring station and dramatically lowering overall costs.

At Control 2023, Mahr will debut the new development using a MarSurf contour and roughness measuring station. Customers that want to quickly and constantly evaluate large numbers of a recurring workpiece will find this to be especially useful.

Robot automatically removes workpieces

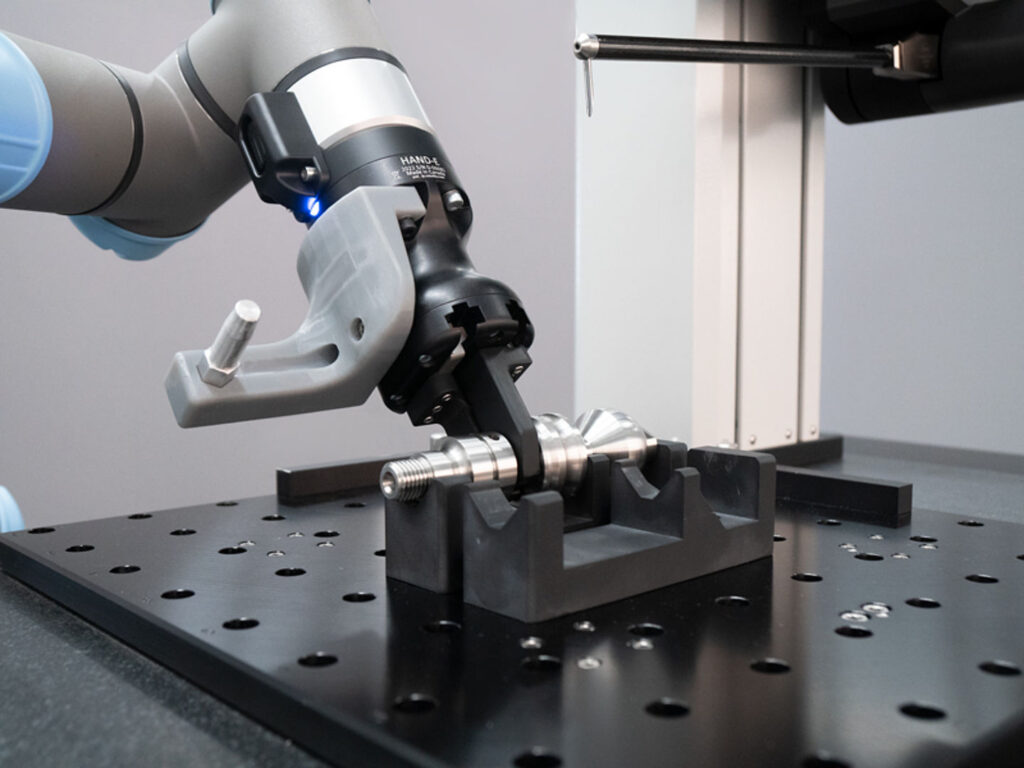

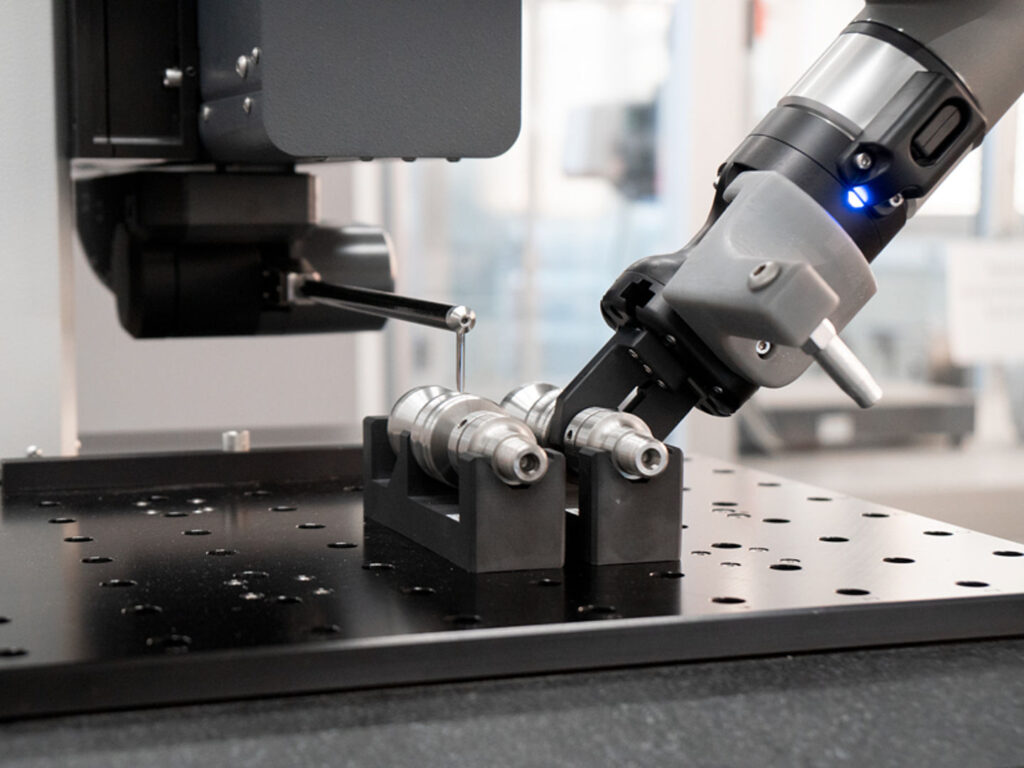

The system consists of a storage unit for workpieces with pull-out magazines housing the measurement-related components. The workpiece storage box houses the MarSurf measuring station, which has a robot arm attached to the side for easy access to the magazines. The gripper, which was 3D printed to fit the component perfectly, is pulled out by the robot and used to remove it. The measurement is then initiated automatically when it is set on the MarSurf device’s workpiece holder. The robot repositions the component into the workpiece storage after a successful measurement.

Solution with numerous benefits

Customers benefit from many advantages with this system:

- It requires only as much space as a standard measuring station

- No personnel are tied up at the measuring station

- An operator is only required to reload the magazines

- The service life of the measuring device is increased, even three-shift operation is possible

- Depending on the application, even simultaneous loading and measuring is possible

- The robot can be reprogrammed very easily and quickly for other workpieces, making it flexible in use

- Overall, throughput thus increases while costs decrease

As of right now, according to Axel Binder, Director Global Engineered Solutions, “we are planning the robot for MarSurf measuring stations.” However, future developments are also possible for all other measuring stations, such as those used for form measurement with our MarForm MMQ series. The system is applicable to all MarSurf measuring stations in this context, not just new ones. This is due to the fact that Mahr devices that have a long history of successful operation can likewise be retrofitted with it. Overall, we thus provide a standardised and affordable method for pallet measurement, according to Binder.

Click on the following link, Metrologically Speaking to read more such news about the Metrology Industry.