Automated metrology systems are developing as a game-changer in the industry as demand for precision production keeps growing. These technologies are rapidly changing from a luxury to a requirement for manufacturers wanting to increase production and efficiency due to their capacity to expedite inspection processes and remove bottlenecks.

How to Reimagine Metrology with Automation?

How can you get around the production bottleneck caused by metrology? through advancing metrology, utilizing several sensors, clever engineering software, and current technology to simultaneously collect millions of data points. Technology data mining is essential for manufacturers to gain a competitive edge.

Your value chain becomes more accurate than with conventional manual methods thanks to faster data mining, which also frees up the productivity bottleneck in metrology.

Why Modernizing Metrology is Crucial for Improving Your Business Results?

Digital technologies are undergoing a significant revolution in the manufacturing sector, and as a result, more and more manufacturers will be miles ahead of their rivals. Automation and streamlined processes become more prevalent as production processes are modernized:

- Cost savings

- Improved efficiency, and

- Higher quality products

Modernizing metrology can help producers gain a competitive edge, which can have revolutionary effects. Metrology is typically seen as a productivity and output constraint for many manufacturing operations. The incorporation of a modernized industrial chain is essential to reaping the full benefits of digitalization and automation.

But how can manufacturers improve their value chain by integrating modernization into their existing software?

To speed up the process of ensuring quality and completing orders, automate quality management and seamlessly integrate a contemporary production process. This will save time and money and enable scalable output.

It’s crucial to realize that obtaining accurate measurements in metrology can now be a time-consuming process that frequently requires manual operation and many pieces of equipment, taking up to 25 minutes or even hours.

Manufacturers will be able to expeditiously verify quality and complete orders by automating quality control and seamlessly integrating it into the larger manufacturing process. saving money and time while allowing for scaling of production.

A digital approach to metrology enables in-process interaction and modification of the production process, encouraging ongoing advancements and increased consistency in the creation of high-quality products.

The Importance of Data in Metrology – Data Is King

Significant improvements have been made as a result of the digitalization of production processes, including improved traceability of manufactured parts.

Therefore, it is crucial that any method for automating metrology be able to ensure the same degree of accuracy and dependability as present techniques. Speed cannot come at the expense of accuracy.

Additionally, obtaining comprehensive, high-quality metrology data enables manufacturers to quickly and easily produce intelligent Statistical Process Control (SPC) data sets for analysis and production process adaption, as well as digital twins of measured parts.

Even after a part has been shipped out, manufacturers can still extract or compute more information, increasing efficiency and flexibility throughout the entire manufacturing chain. These advantages are only feasible with a new method of metrology that makes use of automated measurements that collect more data. This is made feasible by a new method of metrology that uses automated measurements to collect more data.

Real-life Example: Reimagining Metrology

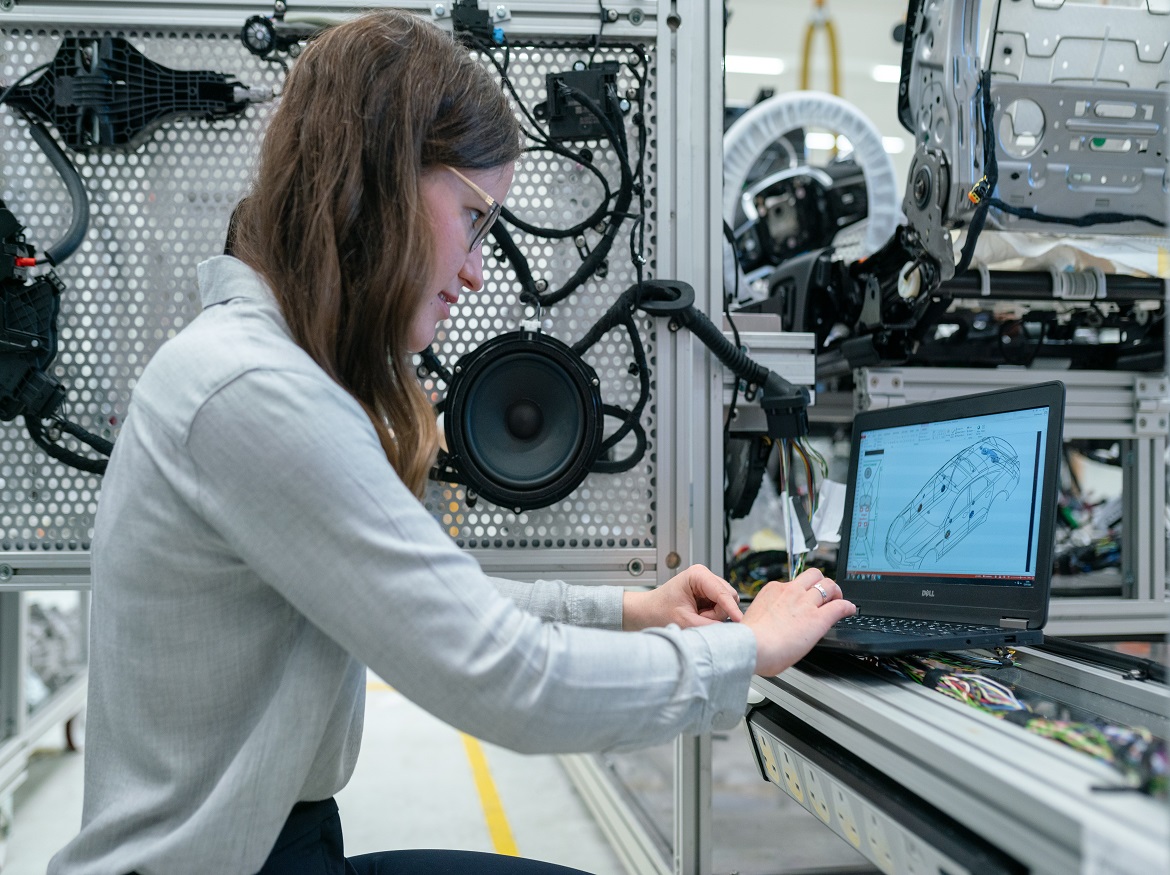

Utilizing many sensors and clever engineering software to simultaneously collect millions of data points is modernizing metrology. Traditional manual methods cannot compare to how much faster and more precise this is.

The underlying idea of Sandvik’s own metrology solution is this. The Metrolog X4 software from the Metrologic Group can be used in conjunction with the ZeroTouch high-speed non-contact inspection platform from DWFritz to give a highly effective and complete metrology solution that generates accurate results and useful data in a market-proven package. DWFritz and Metrologic are both part of the Sandvik Group of companies.

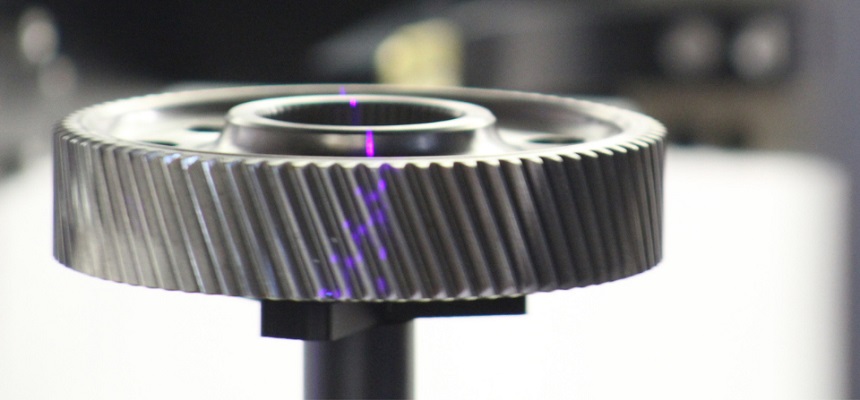

The system’s non-contact feature, which many rigid probes find challenging to measure flexible parts, avoids any problems, and the automation enables a completely dependable and unattended process. Using SPC tools and Quality Data Management (QDM) from DCS, production improvements may be given live with all this data available.

One Sandvik client, a producer of electric vehicles, was able to cut the time needed for essential part measurements and inspection from more than 30 minutes to just under 10 seconds.

Recently, a maker of electric vehicles asked for our assistance in taking precise measurements of a 150-hairpin stator. Its old metrology procedure took 45 minutes and wasn’t efficient enough for manufacturing. Our method decreased analytical times to under 30 seconds and inspection durations to under 12 seconds. This led to a 90x reduction in the time needed for an entire metrology operation.

The use of an automated system with many sensors that measure the full surface of a part in one pass rather than point-by-point with a human tool results in these considerable time savings. The numerous sensors provide a high-density micron-level point cloud that makes it possible to quickly evaluate 100% of the features on every item. The manufacturer greatly increased throughput and advanced production without compromising precision by moving to an automated system. The method enables thorough examination and analysis, but more quickly.

How To Create New Value with Digital Metrology?

The advantages of automation and digitalization go beyond simply improving metrology’s established methods. It can make it easier to adopt new working methods in which measurements are taken more closely after the machining operation. Additionally, manufacturers are able to adapt and change their processes in real time, improving product quality and minimizing waste, thanks to the ability to gather, analyze, and act on the enormous volumes of data generated during the measuring process.

Data is a precious commodity in the current digital era, and digital metrology gives manufacturers the chance to future-proof their products and acquire a competitive edge. Through continuous data flow, it helps close the loop and decrease “islands” on the shop floor.

Because so much data is produced, it is possible to create a digital twin of each component that is measured, enabling real-time part validation. Increased traceability and comprehensive data, such as full SPC analysis and process monitoring with QDM solutions, enable manufacturers to instantly improve the effectiveness and performance of their goods. Digital metrology also promotes design improvements in the future, providing clients with more long-term value and quicker delivery.

Today is The Future of Metrology – Digitalization and Automation

Digitalization and automation are clearly accelerating forces in the manufacturing sector, as are becoming more and more clear. Critical measurements don’t have to be a bottleneck for development any more thanks to the development of automated metrology. In reality, metrology and quality management can operate as your “eyes and ears” on the factory floor and as a business enabler in the value chain.

Automated quality management enabled by AI advancements may help manufacturers “close the loop” even more and elevate production and product quality as technologies evolve. However, for the time being, manufacturers can benefit and have opportunities thanks to 100% measurements, real-time modifications, and intuitive development.

Credits: Manufacturing Solutions Sandvik

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.