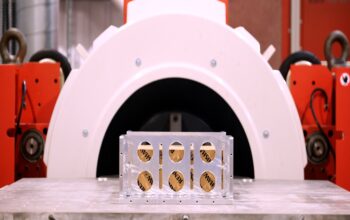

The two main components of the MES measuring station are, firstly, four MarSurf M 310 roughness measuring devices, which are actually mobile and combined in a special design as a stationary unit. They each have a double-skidded probe system. This means they meet the roughness standard applicable to sheet metal in accordance with DIN EN 10049:2014-03 and can measure the required roughness of Ra 0.25 µm.

Secondly, the measuring station is equipped with a collaborative robot including workpiece storage, the so-called MahrFeeder. This automatically removes the sheet metal samples from the magazine, scans the applied QR code for identification and documentation and positions them in the measuring device. The samples are then measured from both sides and either approved or rejected depending on the result.

The advantages of this solution for the customer are manifold:

- By measuring only a very small sample, the customer can make a reliable quality statement for the entire coil.

- No personnel is required for measuring. An operator is only required to reload the samples into the workpiece storage.

- The service life of the measuring station is increased and even three-shift operation is possible.

- Overall, this increases throughput while reducing costs.