Proven in the most challenging application environments CAMIO is the CMM software of choice for many of the world’s largest manufacturers. By leveraging the productivity benefits of CAMIO, manufacturers can focus on accelerating lead times and improving product quality while reducing costs. CAMIO’s interoperability across CMM platforms, sensor technology and manufacturing sites, is a unique advantage which guarantees the sustainability of your investment in software and inspection programs.

Market leading innovation software for CMM

LK Metrology is celebrated for its pioneering CMM hardware and software, achieving several industry firsts like the inaugural bridge-style and high accuracy horizontal arm CMMs, alongside the first CMM-specific software. Their technology supports a wide range of industries – from automotive to aerospace and beyond – through every production stage, enhancing quality, efficiency, and cost-effectiveness. CAMIO, their flagship software, offers tailored solutions for both small and large operations, ensuring businesses maintain a competitive edge by leveraging the most advanced metrological technologies.

Highlights

This new version demonstrates a strong development commitment and direction for the platform, with key new functionality and significant advances particularly for automated programming.

- New Clearance Box for collision avoidance

- Enhanced Automatic Sensor Search

- Redesigned Manual Touch window

- Improved visualisation of CAD features

- New CMM Configuration Utility

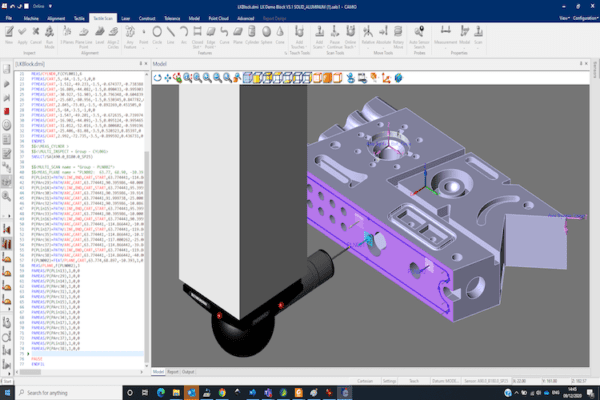

Clearance Box

This new planning aid improves programming efficiency by automatically adding safety moves to ensure the probe path is safe.

When moving between measured features or changing the probe head position, any required probe clearance moves are automatically added to the program to avoid the probe colliding with the workpiece.

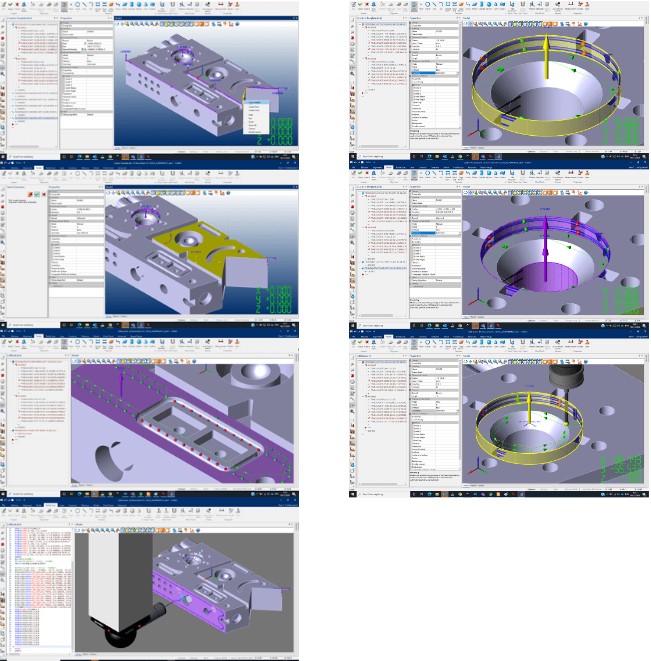

Sensor Search

Auto Sensor Selection works with the new Clearance Box to ensure collision free probe paths when changing probe positions between measurements.

Overall program efficiency is improved automatically, by keeping the total number of probe positions used to measure the part to a minimum.

CAD Visualization

To enhance the user experience, CAD features are now shown as transparent, this allows easy access to the drag-and-drop tools when configuring the measurement strategy.

Manual Measurement

A new design of Manual Measurement window, with large display counters, improves the visibility of touches when measuring features, particularly when operating CAMIO from a distance.

CMM Settings Utility

This new standalone utility enables setting from one CMM installation with CAMIO to be copied to another.

Copying CAMIO settings can provide an important back-up, as well as assisting customers when harmonising CMM settings across multiple installations.

Modules