Gocator® 3d Laser Point Profilers

In the international road and railway business, Greenwood Engineering, based in Denmark, is the top provider of specialized measuring equipment for exceptional situations assessments. Their extensive product line includes everything from small, portable MiniProf units for tracking and analyzing the cross-sectional profile of train wheels, rails, and brakes to the truck-sized Traffic Speed Deflectometer (TSD) for measuring bearing capacity at the network and project levels on roads while traveling at the speed of normal traffic.

The Application

It is difficult for all road and highway agencies to assess pavement conditions. The reason for this is that the subject of the assessment is an essential component of infrastructure, and quality and dependability are directly tied to the general welfare, comfort, and productivity of society.

The Challenge

Traditional stop-and-go sample techniques, such as the “Dipstick” and “Rod and Level” procedures, are accurate yet time-consuming and labor-intensive. Throughout a session, data points are manually gathered and processed to get the necessary results. Although these techniques have been tried and true to create reliable and useful data, they do so at the expense of productivity and safety because they necessitate the sluggish and even motionless physical presence of people near moving vehicles.

The Solution

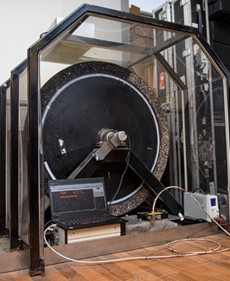

Greenwood Engineering started an internal inquiry to look at the accuracy, noise, and stability of the platform in order to assess the effectiveness and practicality of the LMI3D Gocator 1300 series of Laser Point (Displacement) Sensors in a traffic speed road profiling scenario.

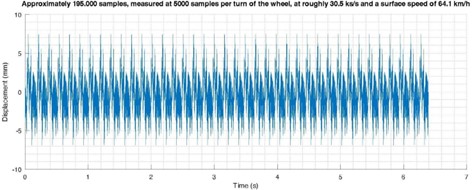

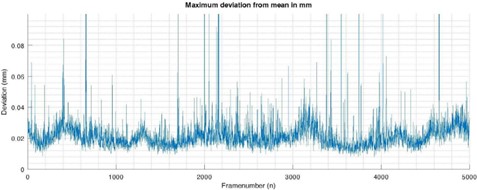

The LMI3D Gocator 1350 and 1365 point profilers were put to the test using a specially designed test stand that accurately simulates real-world road profiling circumstances. A circular asphalt wheel’s displacement data was gathered over several consecutive rotations at highway speeds and analyzed after the fact Information regarding the system noise floor is revealed by wrapping all the data onto itself as a function of wheel position.

The Result

Operators examined the data generated by the LMI3D Gocator Laser Point Profilers in the Greenwood Engineering test stand and found that the deviation under the tested conditions was approximately 23.4 m, and the RMS noise was approximately 47.4 mRMS. The sample distance was 584 m at a surface speed of 64.1 km/h.

These test results led Greenwood Engineering to the conclusion that the LMI3D Gocator 1300 Series significantly outperforms conventional techniques in terms of sampling rate and precision. The high level of safety, productivity, and dependability that Gocator’s high-precision surface displacement data offers Greenwood Engineering Profilers and Profilographs’ operators enables them to deliver highly accurate road surface profiles that can be extracted continuously at traffic speed.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.