Toshiba Hydro Power (Hangzhou) Co., Ltd. (THPC), a joint venture between Toshiba of Japan and Power Construction Corporation of China, is looking for a new technology called “3D scanning” to make sure the hydropower equipment it makes is of high quality and to offer cutting-edge products to customers all over the world.

The company, which has been in the hydropower industry for a long time, is committed to creating cutting-edge products and technologies, particularly for the design, development, and production of hydropower equipment.

Hydropower is a clean, renewable energy source that can benefit society and the environment in a number of ways. It has the potential to lessen reliance on fossil fuels and increase energy security. As a result, increasing the quality of hydropower equipment can assist in maximizing this renewable energy source’s benefits.

The large-scale equipment that is utilized in the hydropower industry necessitates significant investments and high maintenance costs, despite the industry’s rapid expansion. In order to cut costs and increase productivity, manufacturers of hydropower equipment must improve product reliability from design to manufacturing.

We heard from Toshiba Hydro Power (Hangzhou) Co., Ltd.’s Mr. Sato about how they worked with Scantech to use 3D scanning to improve inspection.

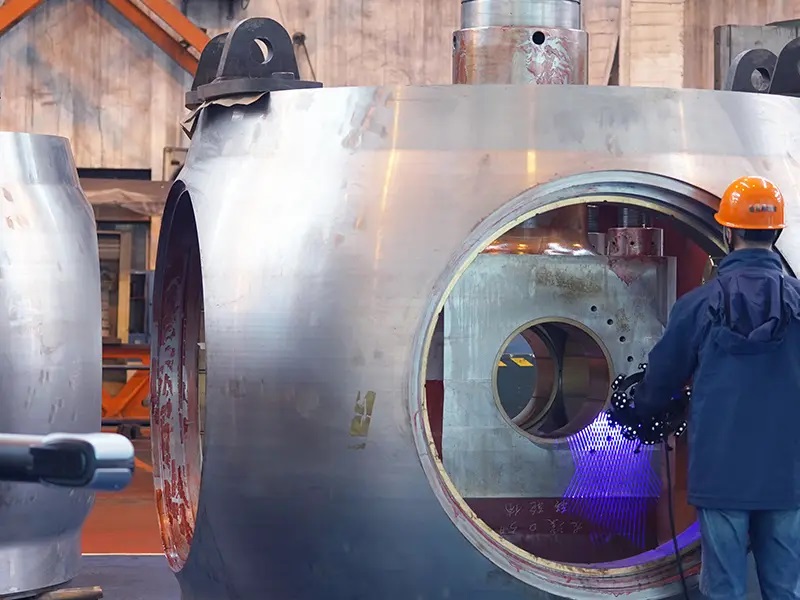

Hydropower equipment is made up of large, intricate parts that are affected by a variety of things when it is made and used. Vibration, humidity, temperature, acid and alkali corrosion, among other things, are some of these factors. Great parts can guarantee the exhibition and life expectancy of the hardware, as well as the productive and stable activity of the hydropower unit. Along these lines, the hydropower gear producers can advance their advantages.

This story’s manufacturer wants to create more advanced equipment to increase capacity, speed, and effectiveness.

How a 3D Scanner Helps to Inspect Hydropower Equipment

Some of the drawbacks of traditional measurement methods include their slow efficiency, high staffing requirements, and lengthy duration. In addition, these approaches are unable to provide comprehensive measurement data for subsequent analysis or intuitive reports. These methods are unable to provide comprehensive guidance for subsequent maintenance and repair due to the lack of data. This is because without complete measurement data, operators and engineers cannot predict or evaluate the equipment’s operating conditions.

For manufacturers of hydropower equipment, high-tech 3D scanning offers more varied options for product design, production, and even maintenance. Scantech’s cutting-edge optical 3D laser scanner, TrackScan-Sharp, enables operators to carry out NDT testing on equipment to guarantee its quality. High quality contributes to reducing losses, increasing efficiency, and extending the service life of hydropower systems.

Regarding the use of the TrackScan-Sharp, Mr. Sato stated, “The TrackScan-Sharp can swiftly gather 3D data of parts using optical tracking, and no targets are needed. Its 6-m tracking distance is impressive. When compared to standard optical tracking systems, it is very effective. Operators don’t need to move the tracker around frequently to scan the entire part because to its wide working volume.

It is portable and lightweight, making site setup simple. In factories, the working environment is frequently unpleasant. The minimal footprint of TrackScan-Sharp and its high degree of environmental adaptability make it ideal. It can be applied on the spot to complete tasks.

TrackScan-Sharp can meet our needs for quality control and help us deliver high-quality products faster to our customers.”

Advantages of Optical 3D Scanning System

Free and wide-range measurements

The optical tracking system provides high-resolution and wide-range measurements using a 25-MP industrial camera and a 49-m3 tracking volume. Without often moving the tracker, it may collect data over great distances and in a wide range. The big hydraulic turbine blades, runner of the pumped storage unit, generator wire rods, and other large parts are perfect for measuring thanks to this.

High-precision measurements for various scenarios

With 0.049-mm volumetric accuracy for 10.4 m3 small-range tracking, 0.067-mm volumetric accuracy for 28.6 m3 medium-range tracking, and 0.089-mm volumetric accuracy for 49 m3 large-range tracking, the system combines cutting-edge hardware and a reliable algorithm to deliver high-precision measurements for different tracking ranges. It is simple to record the minute features of various medium and big hydropower equipment components.

Advanced and efficient 3D scanning

Without any targets, TrackScan-Sharp can scan the entire component, saving time on sticking and removing them. Additionally, it enables the simultaneous scanning of several parts, improving measurement efficiency.

Real-time inspection reports

Powerful 3D software that can record, analyze, and save data in real-time is available with TrackScan-Sharp. Hydropower equipment can be scanned, and point clouds can be processed to create color maps. The 3D data can also be kept in the database for later archiving. To produce high-quality goods, TrackScan-Sharp provides a detailed assessment of the part conditions.

In the field of energy engineering, Scantech’s 3D scanners and 3D solutions are frequently used for inspections of hydraulic turbine guiding vanes, turbine castings, oil and gas pipelines, wind power flanges, etc. It supports the digital transformation and modernization of numerous large-scale energy organizations.

Click on the following link Metrologically Speaking to read more such case study about the Metrology Industry.