To ensure safety on board aircraft, door latches are secured with special covers that prevent unintentional opening after landing. These covers are increasingly being produced

Category: Case Studies

A New Method for Incoming Material Inspection: SHINING 3D Automated Inspection System

Incoming Material Inspection is a critical quality control step in production. By pre-checking raw materials and components, we ensure they fully comply with regulations and

Marine Engineering: 3D Scanning Solution for Ship Turbine Blade Inspection and Product Development

The marine engineering industry plays a crucial role in global transportation and commerce, focusing on the design, development, and production of boats, ships and other marine

Cambridge research team decode ancient collaboration with Artec Space Spider

TheREVERSEACTION project team is on a similar journey: investigating how complex technological systems were sustained in ancient societies without strong political leadership. By integrating archaeological evidence

Automotive Assembly Using Vision Guided Robotics

Detecting and Testing Electric Car Doors In automotive production, various components must be located and tested along the assembly line before finalizing the cars. Electric

The Connection Between Quality Control and Customer Satisfaction

The key to customer satisfaction Precision Quality Control with EDAS. Why Quality Control is key to customer satisfaction Customer satisfaction relies on consistently delivering reliable,

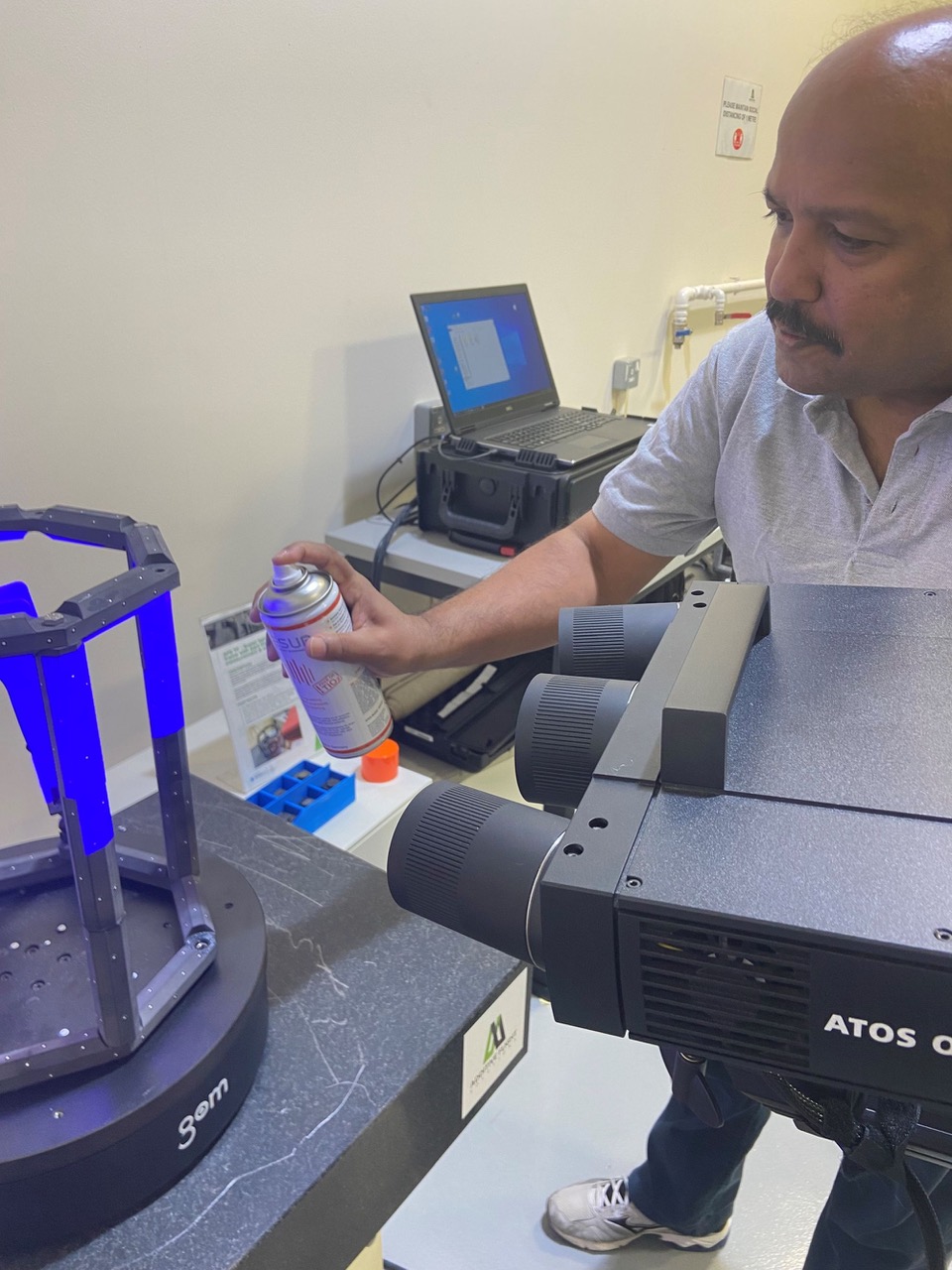

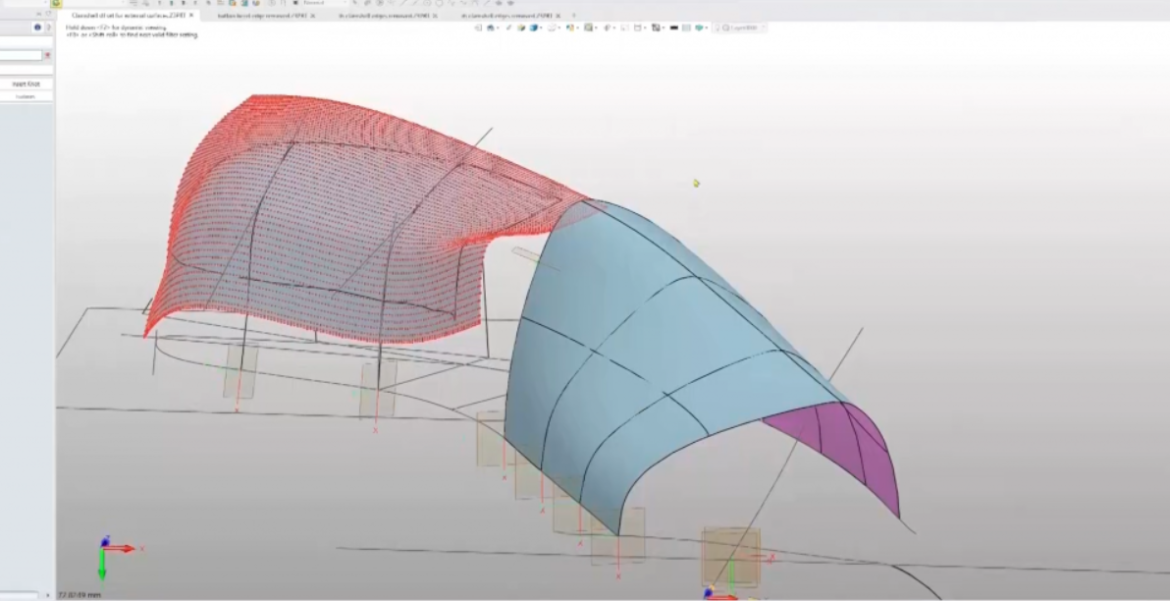

Mastering Scan to CAD: Starting with Tips for Preparing Scans to Complete CAD Models

Scan to CAD workflow is the process of scanning a physical object and inputting the data into CAD software. The benefit of reverse engineering an

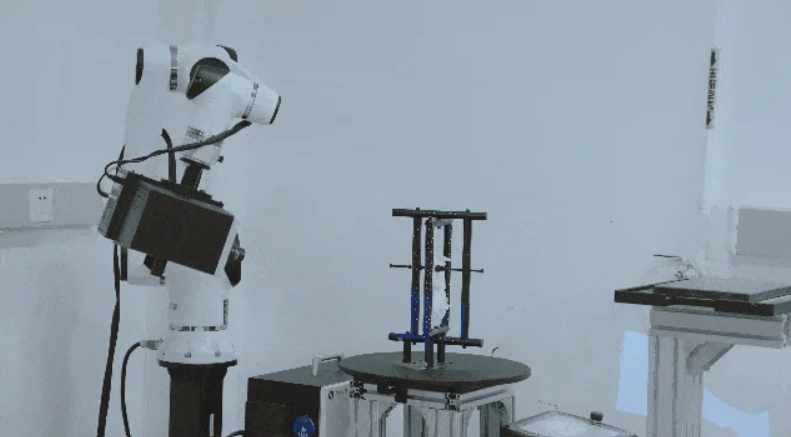

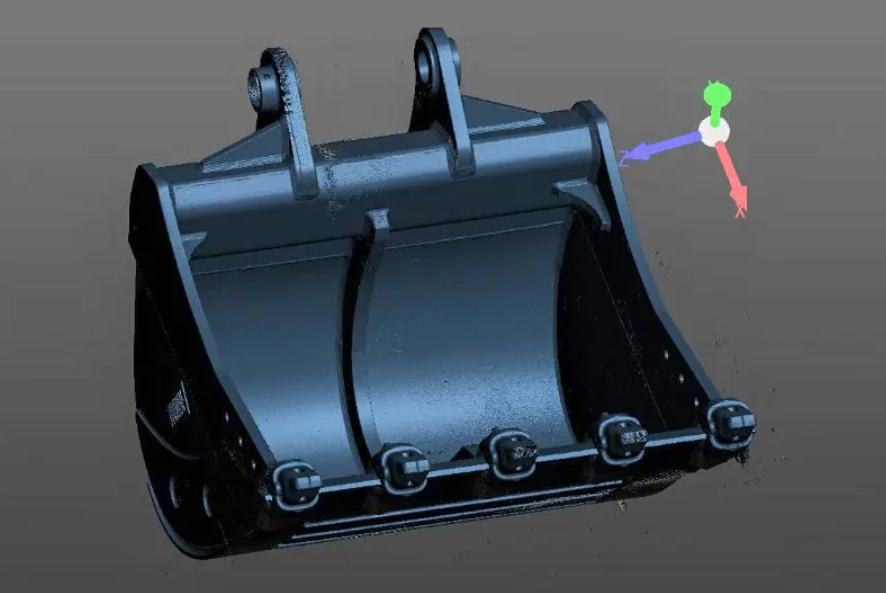

Improve Product Development of Heavy Construction Equipment with Scantech’s 3D Solutions

The heavy construction equipment manufacturing industry originated in the late 1800s and has since undergone significant advancements. Ensuring high-quality manufacturing is crucial, as these machines

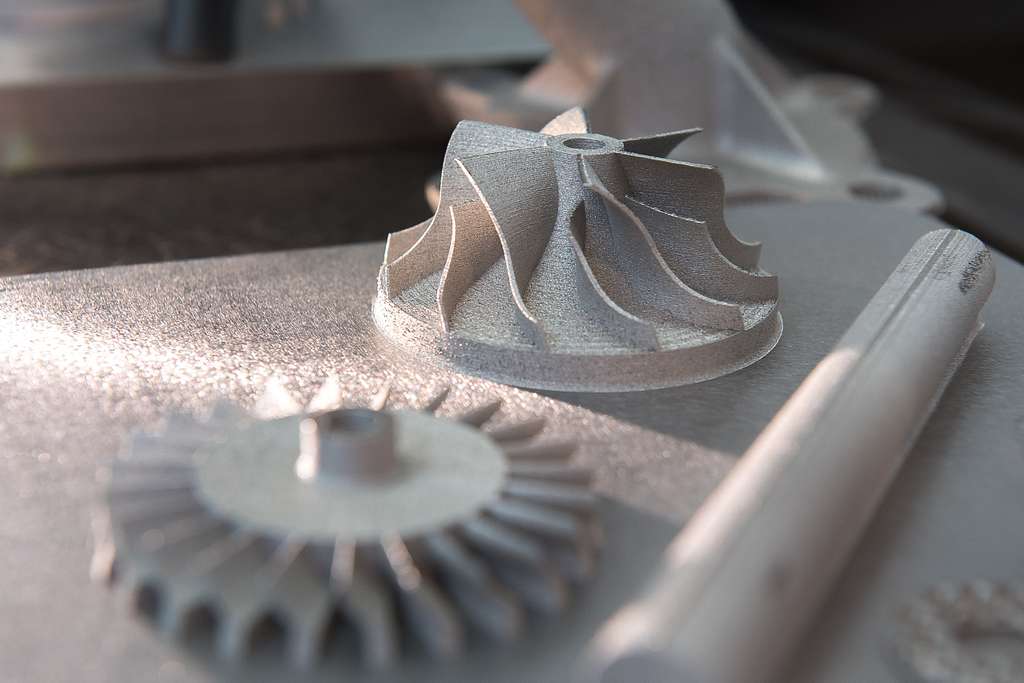

Non-Destructive Testing of Additive Manufacturing Defects in SS316L

AM is increasingly utilized in aerospace applications for producing intricate engine components and critical replacement parts. However, the quality control of AM-produced parts presents unique

Welding Bead Defect Detection Using AR + AI

Cars have multiple complex surfaces and features, leading to variations in welding locations and techniques. The examination of automotive welding quality requires inspection from multiple