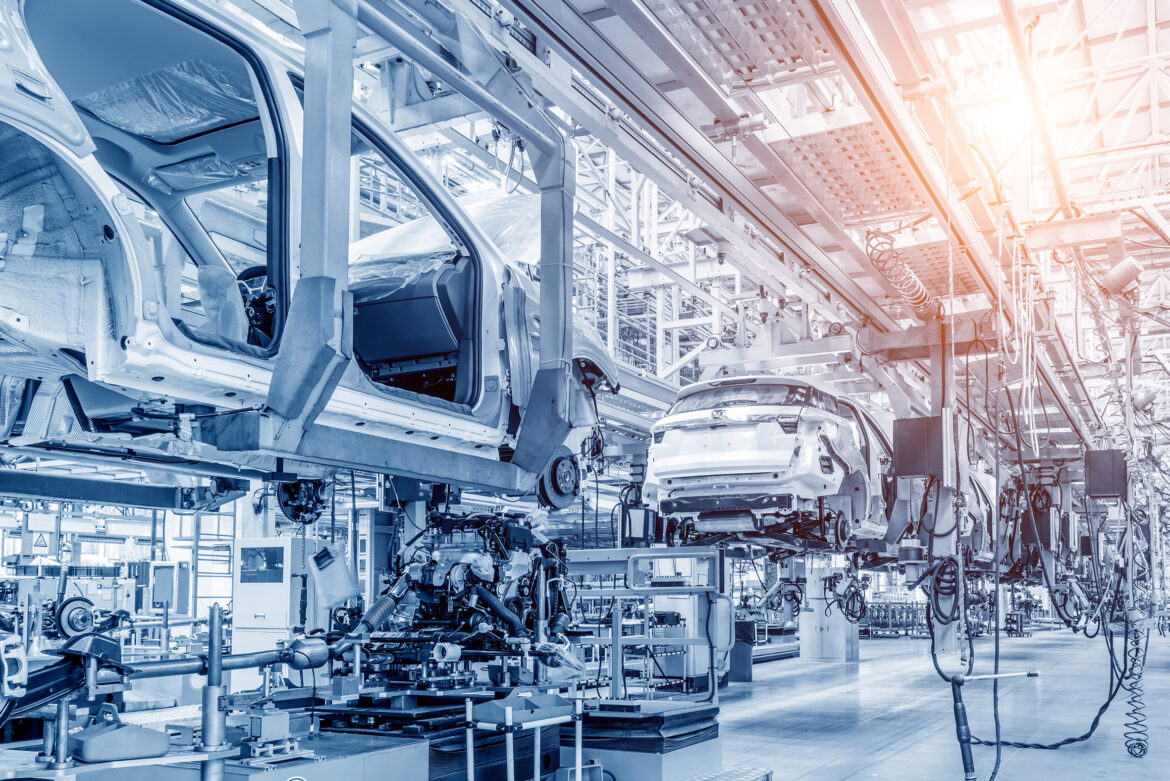

Quality Testing for Automotive Door Assembly Lines Car door buttons are vital in the manufacturing and assembly of vehicles. Despite their small size, these buttons

Category: Case Studies

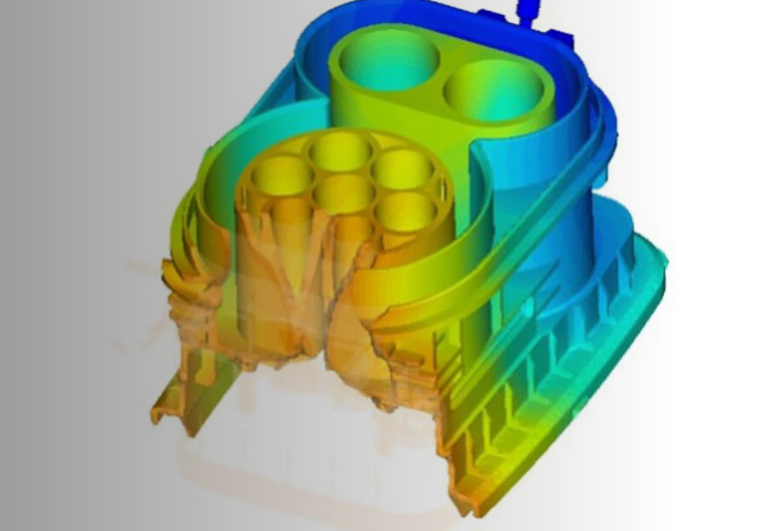

How CT Data Analysis is helping TE Connectivity Reach Their Ultimate Goal of End-to-End Quality Inspection

Manufacturer gains critical insights using Volume Graphics software throughout design, simulation and manufacturing. The all-digital movement is winning over manufacturers seeking more automation, connectivity and

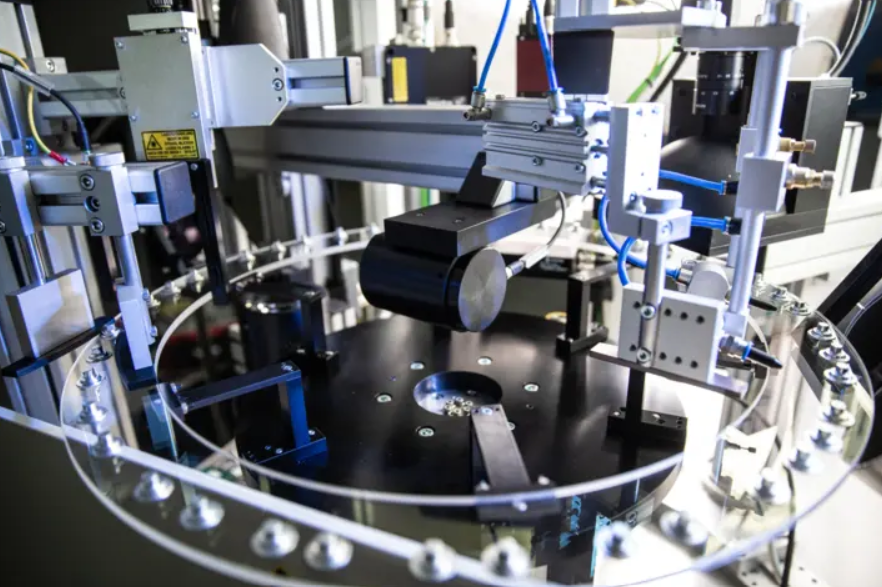

Plogsties: vision systems from Kistler provide optical quality inspection for fasteners

What’s the most efficient way to ensure the quality of millions of mass-produced series parts used in highly demanding, safety-critical applications? Plogsties meets this challenge

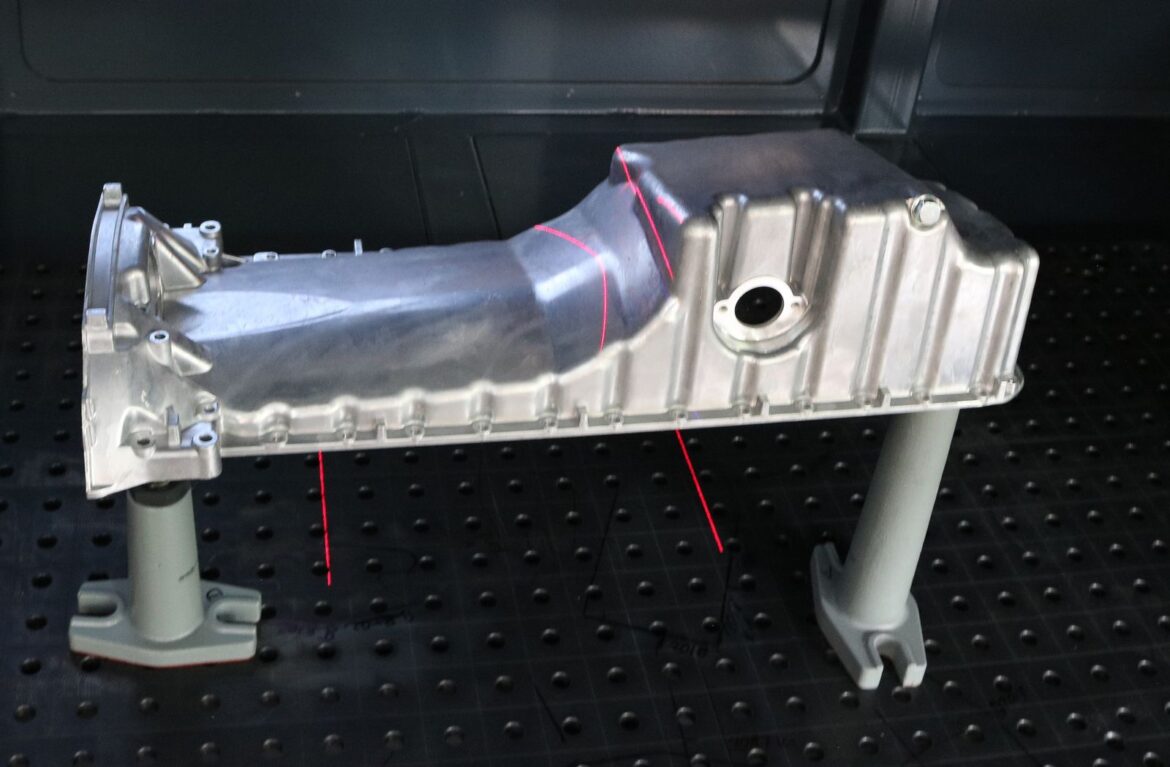

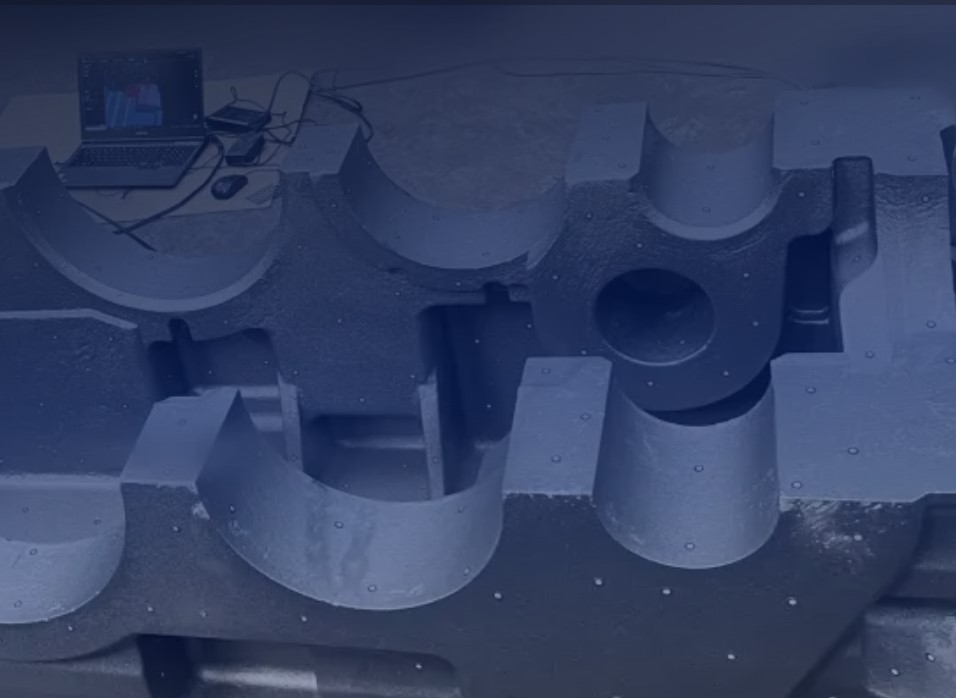

Aluminum Die-Casting Scanning Without Shading

Introduction: Quality assurance in the automotive industry is crucial, with little room for error. Ensuring that large assemblies, such as oil pans and other aluminum or

Complete 3D Scanning Solutions For Education Powered By Verisurf

Scantech iReal M3 Color Scanner powered by Verisurf Software Advanced manufacturing industry demand for trained Verisurf metrologists and job opportunities for people with

Pioneering Precision: The Collaboration Behind Landmark Projects in Metrology

In the world of metrology, precision is paramount. From constructing massive structures like the Las Vegas Sphere to ensuring the pinpoint accuracy required in advanced

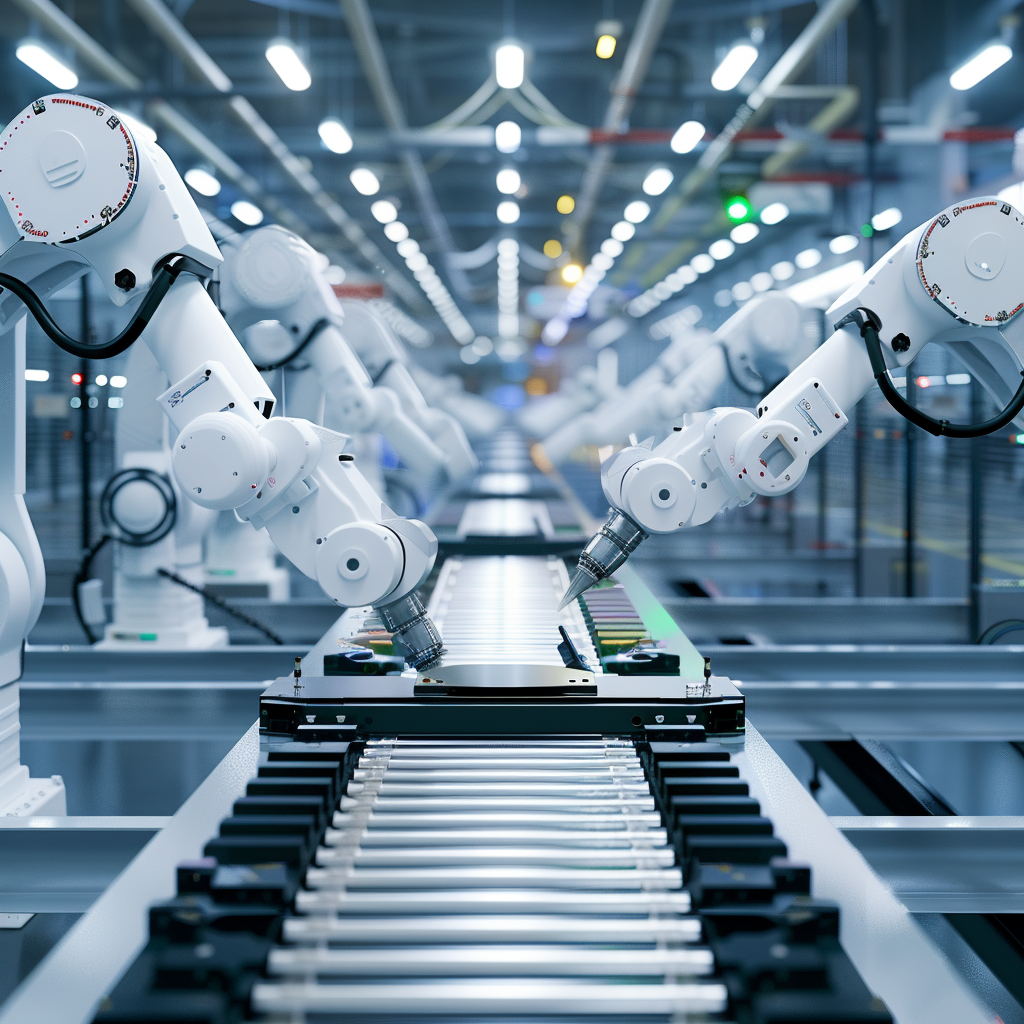

The Role of Quality Control in Supply Chain Management

In the world of manufacturing, quality control isn’t just a box to tick—it’s the silent engine powering product consistency, reliability, and compliance. By catching defects

3D Scanning Boosts Reduction Gearbox Housing Inspection Efficiency by 30-Fold

Using the FreeScan UE 3D scanner has significantly increased the efficiency of large reduction gearbox housing inspections, achieving a 30-fold improvement. This case study explores

Customizing pipe repairs with Artec Leo to keep oil & gas refineries running

Challenge: Accurately measuring complex, damaged piping and equipment in hot, cramped refinery conditions so that custom repair solutions can be designed, manufactured, and installed to carry

Endeavor Air expands dentCHECK use to enhance the quality and efficiency of dent-mapping workflows.

“dentCHECK was the right device to expand our capabilities and advance Endeavor Air’s efforts of integrating more technology in our hangars,” said Bob Olson, Director of Quality