The paradigm change towards flexible manufacturing is already taking place at Mapvision. We will serve as the smart factories’ eyes. Mapvision has had a clear

Category: MS Blog

3D Scanning an Electric Car is Part of R&D

This post will describe how Top3dShop scanned an electric vehicle for EVTech utilizing a RangeVision PRO 3D scanner. The project’s goal was to update the

The Efficiency of 3D Scanning in Reverse Engineering

It may come as a surprise to people living in the digital age to find that there are many things in the world without a

Metrology Goes Inline

Fully integrated metrological solutions are being used in the lines of an increasing number of body shops. They seek to boost the throughput of measured

Metrology Matters: Find Your Ideal System

The ideal metrology system for your application is something you want whether you’re replacing or buying equipment for the first time. Which inspection system will

Precision Meets Efficiency with KITOV CAD2SCAN

KITOV CAD2SCAN is a highly innovative technology that is changing the way companies approach reverse engineering and quality control. This technology is a game-changer in

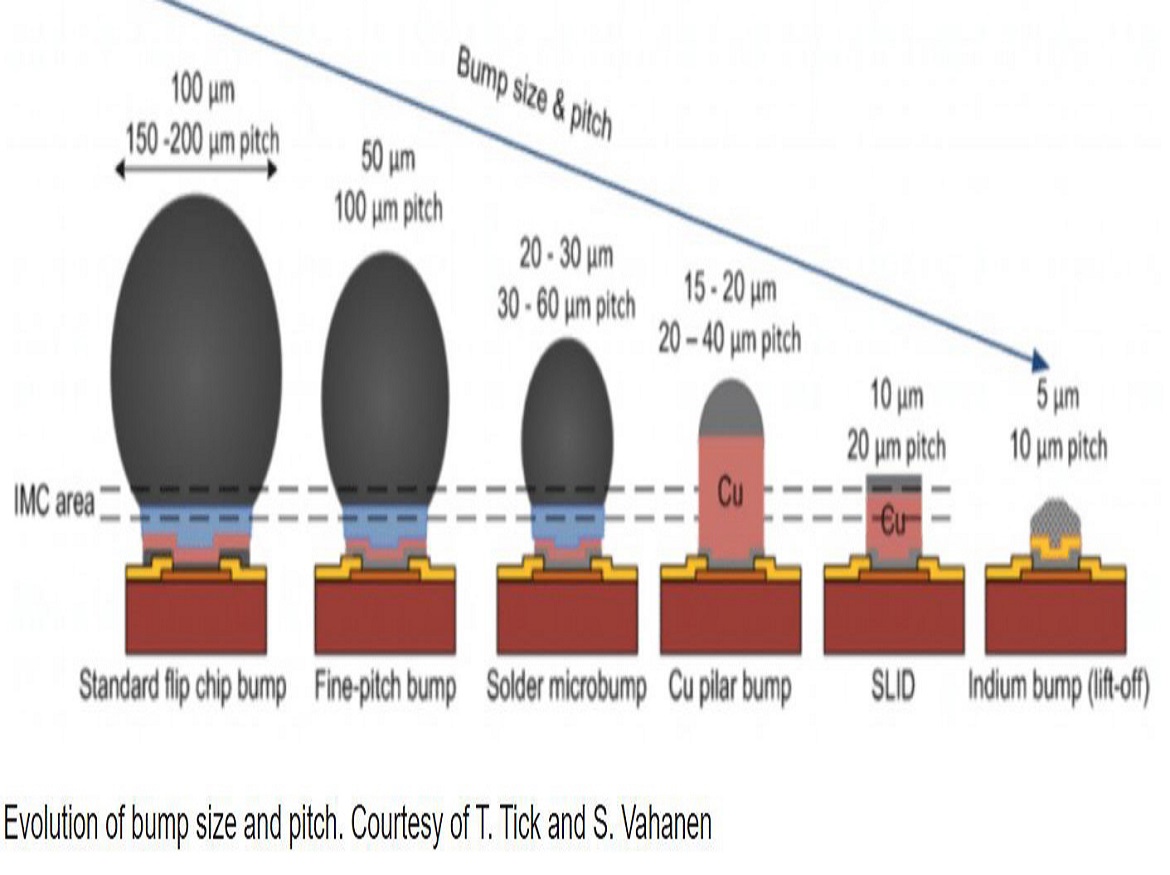

Improve Yield with 3D Inspection by Measuring Bump Height Uniformity

Read the latest technical article published in Chip Scale Review. The capacity to process hundreds or thousands of dies simultaneously and the small container size

Unleashing the Power of 3D Scanning with ATOS ScanBox

Continuous quality control is made feasible thanks to ATOS ScanBox. Automatic optical 3D measuring devices streamline your operations, spot errors early, and maintain your competitiveness.

Use of 3D Scanning in Car Tuning

In today’s world, 3D technologies are frequently applied in the automotive sector. In addition to being employed in automotive design, 3D scanners are also used

Visualizing the Progression of the 3D-Scanning Sector

The global market for 3D scanning was estimated to be worth 7.4 billion USD in 2021. From 2022 to 2028, it is anticipated to increase