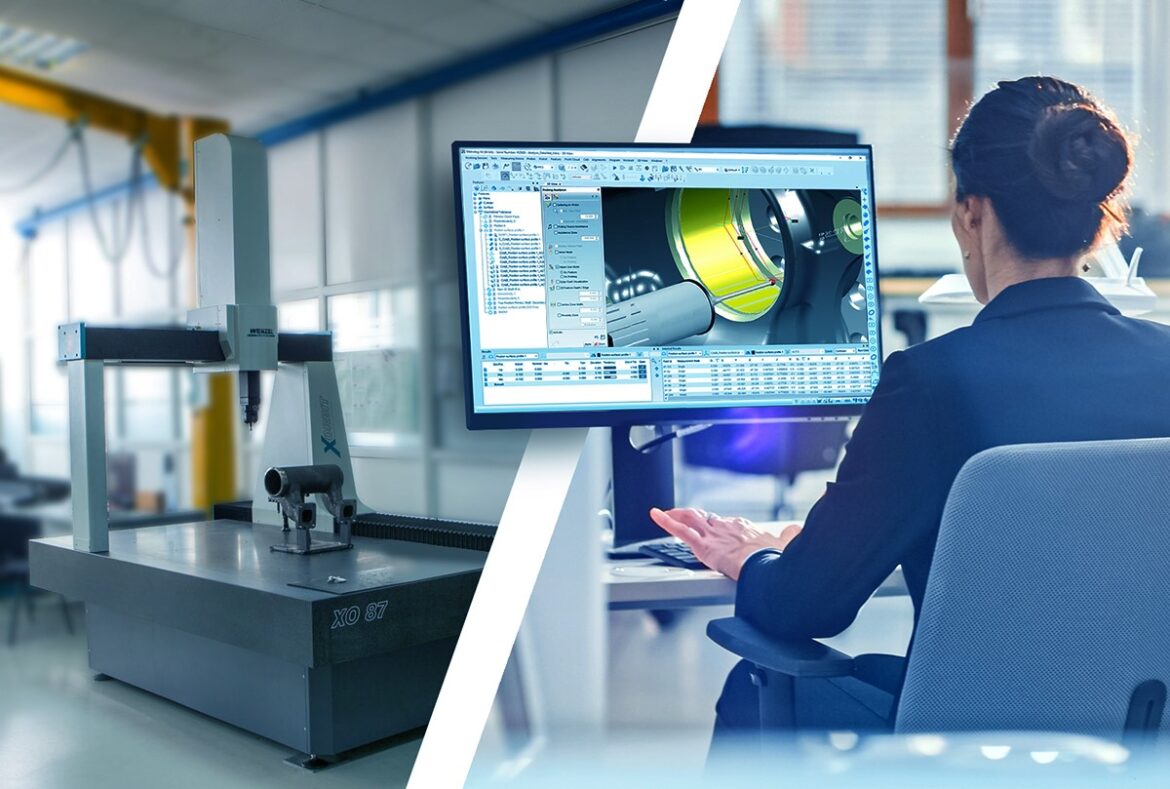

Moving into Industry 4.0 with Off-line Programming Powerful and intuitive, Metrologic Group’s Silma X4 software is an off-line programming tool that allows industrial companies to

Category: MS Blog

How to reuse your targets while improving your scanner!

The below article has been originally written and posted by FRANCOIS LECLERC, and has been re-produced here. Sounds too good to be true, right? And

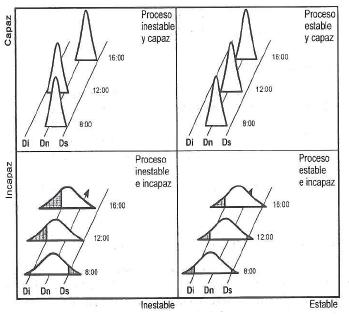

METROLOGY, Key in Quality Control.

The adoption of preventive planning and continuous improvement methods responds to the objective of wanting to create robust products and processes, saving inspections during and

Top 5 Human Errors in Manufacturing

Provide support for error-prone inspection tasks Written by Jonathan Hou, President at Pleora Technologies. For products in the consumer, parts, food & beverage, and print &

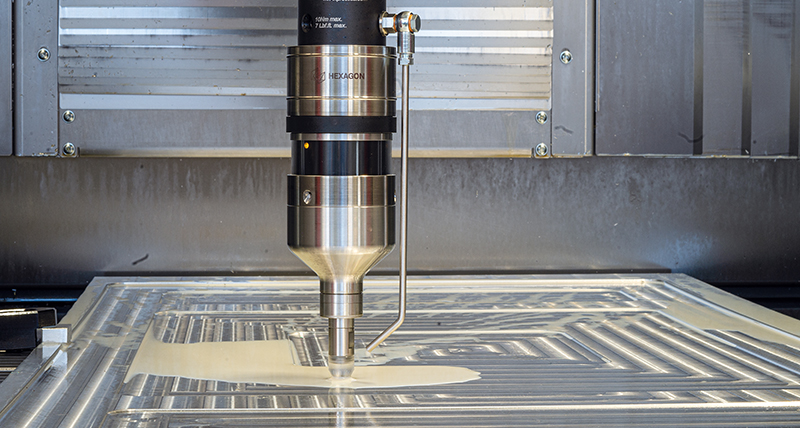

Wall thickness measurement on machine tools now available for wet applications

Hexagon’s Manufacturing Intelligence division has enhanced its ground-breaking ultrasonic probe for automated wall thickness measurement on machine tools with the launch of two new versions

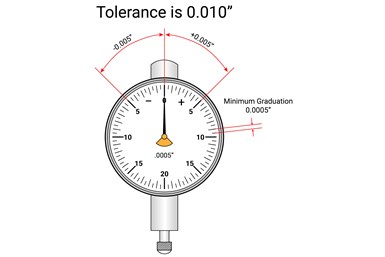

How to Choose the Right Dial Indicator

The article has been originally written by :- GEORGE SCHUETZ Director of Precision Gages, Mahr Inc. Digital alternatives are replacing dial indicators – but dial indicators can

How do I Calculate TUR?

This article is originally written by Henry Zumbrun, President, Morehouse Instrument Company. This article was published as a blog at https://mhforce.com/how-to-calculate-tur/ on Dec. 13, 2021.

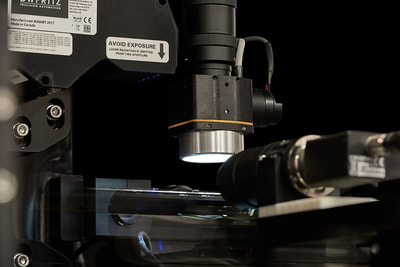

3 Key Benefits of an Automated Non-Contact Metrology System

In the precise world of high volume manufacturing (HVM), microns and milliseconds matter when inspecting medical staples, fitness trackers and smartphones to meet either government

Consumer Goods Inspection and Hybrid AI

Quality inspection of consumer goods ensures products meet specifications, brand criteria for appearance, and mandatory standards for packaging, labeling, and instructions. With increasing consumer demand

The future of metrology

The below article has been directly reproduced as it is for our audience. The below link corresponds to the original article :- “https://www.npl.co.uk/foresighting/metrology” Accurate measurement