Middlefield, CT – Zygo Corporation has announced the introduction of its latest generation of ZeGage™ 3D optical profiling instruments providing precise and rapid non-contact measurement

Category: Category

BAE Systems to recruit record number of apprentices and graduates

BAE Systems is hiring more than 1,250 new apprentices and graduates into its early careers programmes in 2021. More than 850 apprenticeships and 400 graduate

Improving Quality Inspections for Electronics with AI

This article is written by Vesa Tormanen, VP of Product Management and Engineering, Neurala. Manufacturers face immense pressure to deliver high-quality products. Even the smallest

ZEISS’ Fiscal Report Card 2019-20

Fiscal Report shows revenue reaches 6.3 billion euros (-2% vs. prior year) – EBIT at 922 million euros (-141 million euros vs. prior year) Stability

SPIP – Analytical Software for Microscopy

Note, SPIP™ has been replaced by MountainsSPIP®, which is marketed by the parent company Digital Surf SPIP™ or Scanning Probe Image Processor – is an advanced software package for processing and

THE RULER OF THUMB

This article is written by George Schuetz, Mahr Federal Inc. and reproduced from https://www.mahr.de/en-us/Services/Production-metrology/Know-how/Gaging-Tips/Basics-of-Measurement-Gaging-Tips/?ContentID=110464 Many questions have to do with various “rules of thumb” that

O&G production components from Renishaw

For companies operating in the oil and gas equipment-manufacturing sector, recordkeeping and traceability are vital. As part of its company-wide quality protocol, FMC Technologies in

Neurala Launches Industry-First AI Explainability Technology for Industrial and Manufacturing Applications

New technology improves quality control in manufacturing by identifying inconsistencies and anomalies in vision inspection datasets. Boston, MA – December 15, 2020 – Vision AI software

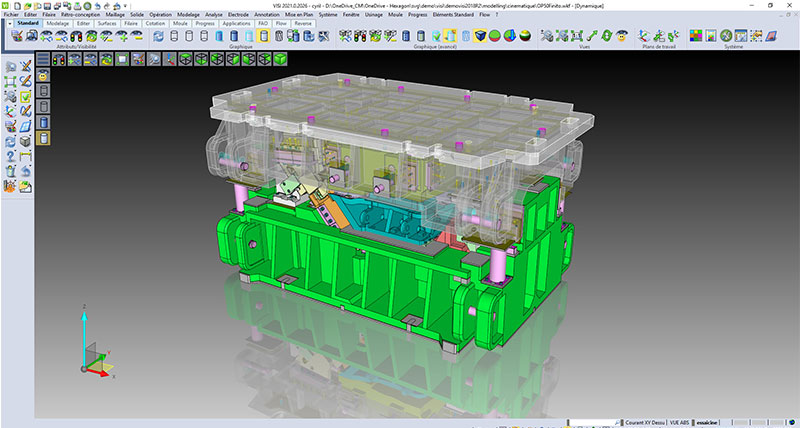

Hexagon to acquire MECADAT AG, master reseller of VISI CAD CAM software in Germany

Acquisition strengthens local support for Manufacturing Intelligence division’s production software portfolio in the region. Hexagon’s Manufacturing Intelligence division today announced the signing of an agreement

LARGE-SCALE 3D MEASUREMENT SYSTEM FOR PARTS UP TO 6500MM

The PolyScan XH is designed to measure part up to 6500mm, combining 2380 scanning units. It’s a versatile measurement system, well suited for automotive sheet