Master3DGage Portable CMM and Verisurf Inspection Suite, $24,995 Verisurf Software, Inc. announced value pricing on its popular shop floor inspection solution – $24,995 for a limited

Category: Category

#HandsOnMetrology Platform for Makers and Manufacturers

New Digital Hub for 3D Scanning The new digital platform HandsOnMetrology.com was set up for companies that want to integrate the benefits of optical 3D

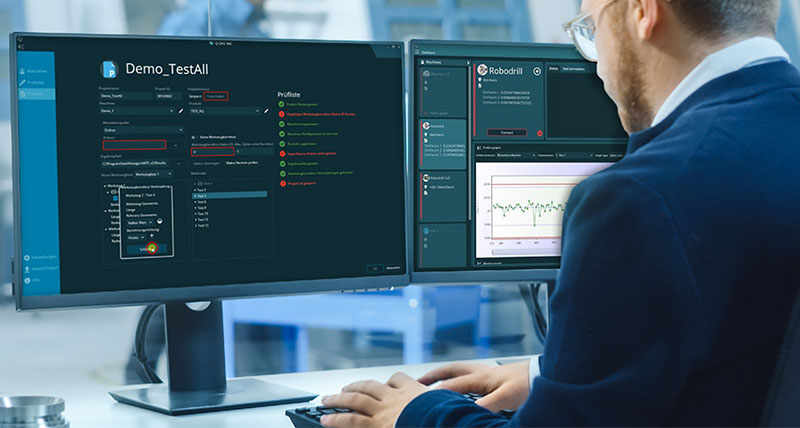

Q-DAS releases Q-DAS IMC version 2

The new version of Q-DAS IMC intelligent machine control software establishes a link between tool data and measured values and enables clear communication between machine

Vertical Focus Probing

Optical Measuring Technique Enables Lateral Probing of Components Up to now, geometries such as boreholes of injection valves in the automotive industry were difficult to

Contest Alert – Product Review!

Review any metrology product and you have a chance to get featured on Metrologically Speaking! Hi fellow metrologists , we are thrilled to share our

V7 CMM Laser Scanner

The V7 CMM Laser Scanner is built using cutting-edge technology that includes the use of the blue laser at a lower price than the competition,

Artec 3D More than Doubles Resolution for Eva and Leo 3D Handheld Scanners with AI-Powered HD Mode

Artec 3D, a world-renowned developer and manufacturer of professional 3D hardware and software, today announces the successful development of a proprietary AI Engine that more

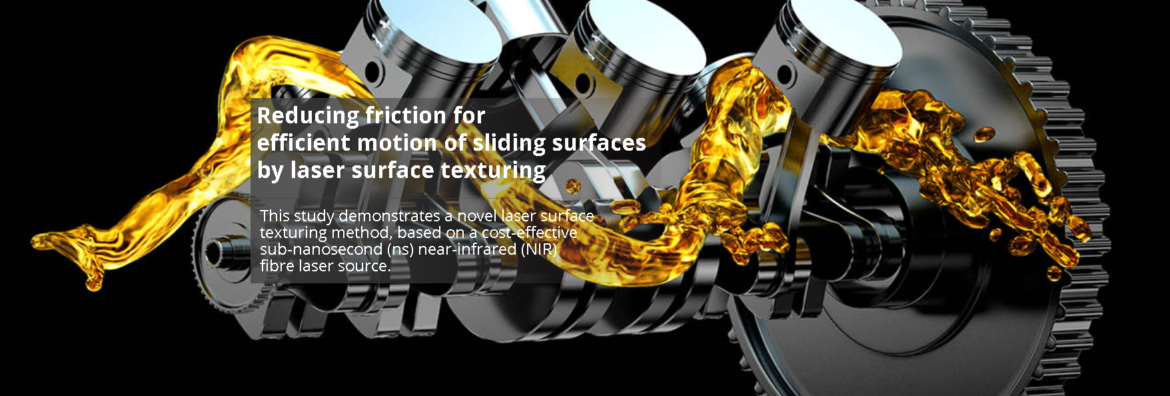

Reducing Friction for Efficient Motion of Sliding Surfaces by Laser Surface Texturing

Energy losses due to friction and wear of sliding surfaces and other tribological contacts account for 23 % of the world’s energy consumption. This figure

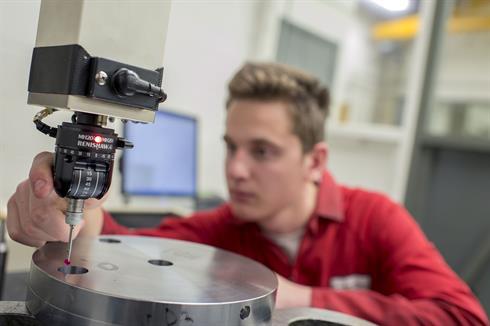

Renishaw probing reduces scrap and saves time at precision subcontractor

The advanced manufacturing division of Intoco (Independent Tool Consultants Ltd) a Gloucestershire, UK, based company, is a showcase for precision subcontract engineering. Five-axis simultaneous machining

Optical Surface Measuring Systems

Fast contour and roughness measurements It’s no longer enough for many workpieces these days to collect dimensional measurements. More and more, it’s necessary to collect