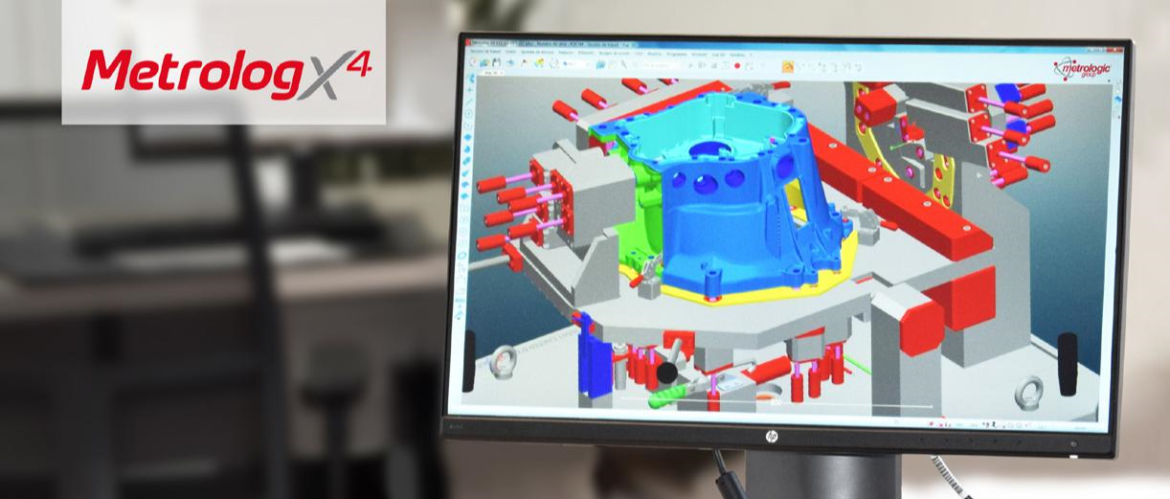

A comprehensive 3D measurement software for the most advanced application Before choosing the 3D inspection software, the company faced several challenges. Performance: First, Opus Solutions

Category: Category

ZEISS Automated Defect Detection

Automated defect detection you can trust The software ZEISS Automated Defect Detection allows detecting and evaluating even the smallest defects in castings reliably, quickly, and

Basler boost with Customized Interface Card in a Line Scan Application

Customers MJV-Sähkö Oy and Lateral Engine Oy Location: Lahti, Finland, and Espoo, Finland Industry: Factory Automation Implementation: 2019-2020 Application MJV-Sähkö Oy delivers machine vision systems

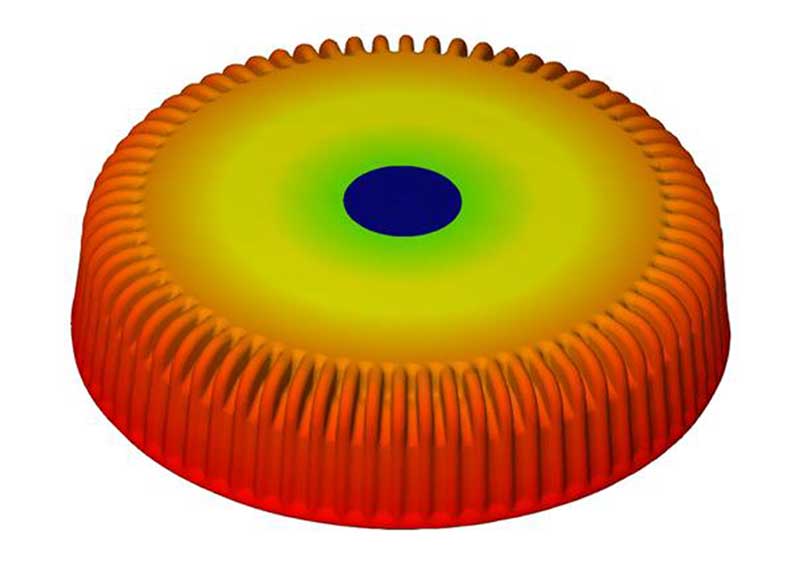

Exact Metrology Performs Bulk Plastic Cap Inspection

Exact Metrology performed a recent inspection on molded caps to showcase the power and capability of multi-part inspections at its Brookfield, Wisconsin office. Computed tomography

MVi5 3D Metrology Center – System Announcement

EDM Intelligent Solutions is proud to announce the release of our new MVi5 3D Metrology Center. The MVi5 combines a rock-solid 5-Axis machine tool motion

Bin Picking Up To 60 Parts Per Minute

Maximum speed thanks to optimum robot path planning and multi-pick function Random bin picking with optical sensors is regarded as the ultimate discipline of automation.

ZEISS Partners With Microsoft

ZIESS partners with Microsoft for better patient care through data-driven healthcare and to enhance quality and efficiency in manufacturing ZEISS Group and Microsoft Corp. announced

Optical 3D Metrology Supports Certification of Airbus A350

To reduce weight and fuel consumption, the aerospace industry increasingly relies on lightweight materials and new material combinations. That’s why the entire fuselage of the

KSCAN 3D Scanner Simplifies Accurate Measurement of Tesla

3D scanning technology has been widely applied in many industrial fields, with the automobile transportation industry a typical example. There is fierce competition between carmakers.

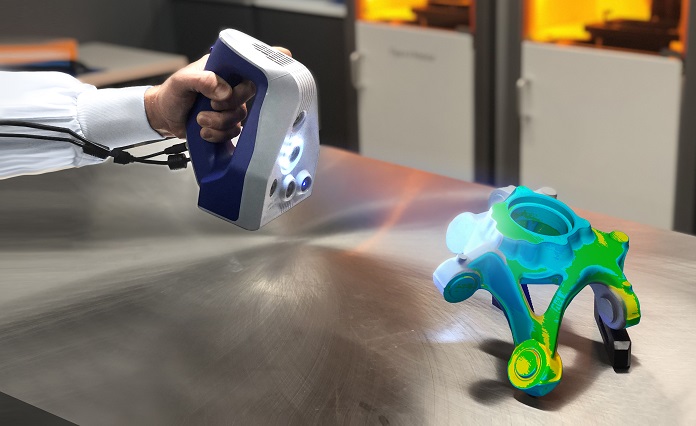

Improved Manufacturing Process with Artec 3D and Geomagic Control X

Scanning and inspective additively-manufactured parts results in reduced costs, minimized iterations, and improved accuracy and quality. As new production technologies evolve new technical challenges arise