This inquiry is common on any shop floor, whether you’re replacing an old profile projector or getting your first measurement tool.

I assume you are familiar with profile projectors. There isn’t much to learn about it once you’re familiar with it again.

The urge to stick with what you know might be strong. Less risk, less interruption, and seamless integration are present. Change is difficult to implement in people, learning new software or interfaces may be intimidating, and optical devices can be quite complex, right?

But let’s look a little deeper.

The projector requires some technical metrology knowledge unless you want to use it to measure the repetitive components you were previously measuring. To perform the measurement consistently and accurately, all operators will need some training and expertise.

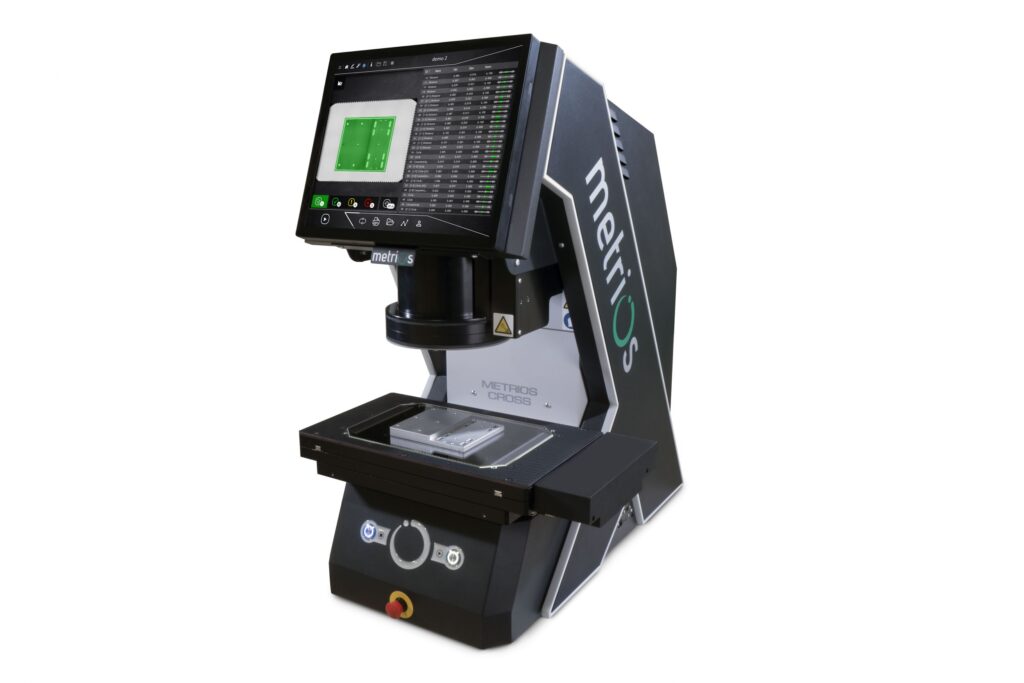

Automatic optical devices can be useful in this situation. It is true that knowledge and experience are necessary for programming the machine. However, once the program is saved, it will be available for all upcoming measures. The metrics that were initially programmed will be available to the other operators with the simple click of a button. In addition to saving a tonne of time, performing the measurements also eliminates the need for staff training and any chance of measurement system misunderstanding.

The projector could seem like the better choice on a small shop floor where the same engineer is measuring distinctive parts with little fluctuation. Optical solutions are the best option when parts change or when numerous operators are using the same machine to take measurements.

How tight are your tolerances, is there decimal, centesimal, or millesimal tolerance?

Both techniques might work if your tolerances are within a few tenths of a millimeter.

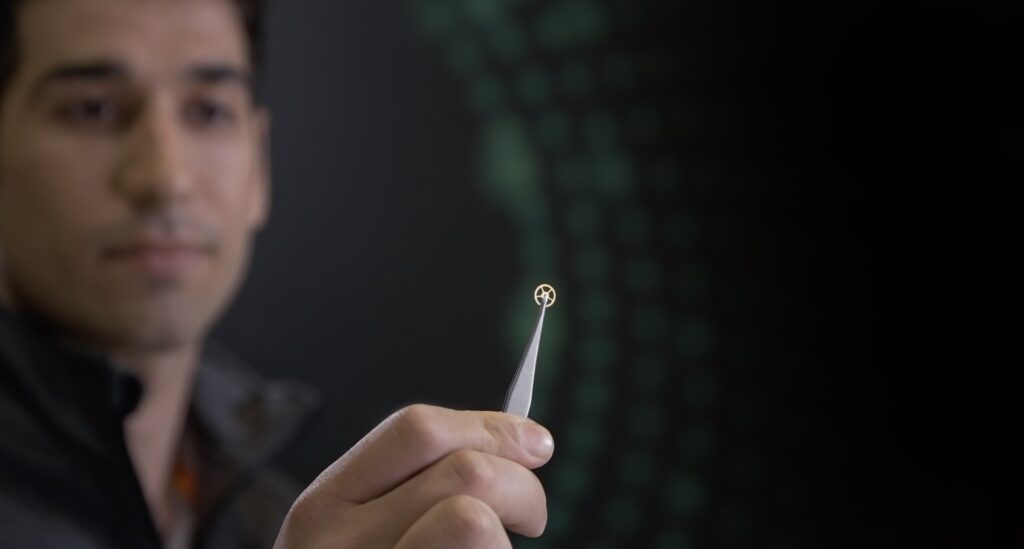

What if your parts have centimeter-level tolerances, though? The profile projector’s limitations will now start to become apparent. Measurement deviations will be clearly detected by various operators. The operator can grow weary, misinterpret the data, or input incorrect numbers. There is no assurance that defective products won’t leave the shop floor when there are so many variables that could go wrong.

In comparison, an optical measurement device will do away with subjectivity while simultaneously providing more accurate measurements.

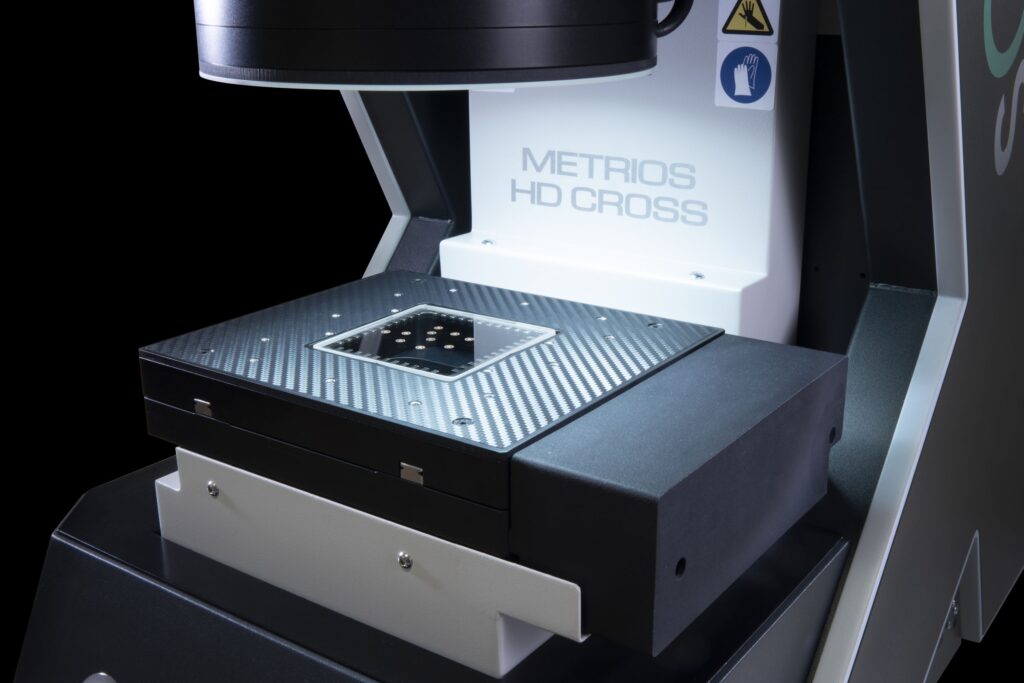

The idea that optical solutions cannot be installed on the work floor is a widely held one.

This has always been true historically. Optical equipment has improved over the past five years to survive challenging shopfloor conditions without sacrificing accuracy.

The automatic optical measurement machine is more expensive than the projector!

An excellent projector will be less expensive than an optical substitute. The ROI on optical solutions is significantly better than traditional methods due to less scrap, higher throughput, and enhanced capabilities, but your company’s reputation is valuable.

Here we are returning to step 1

The projector will take 10 minutes to measure one part, much like any optical measurement device. The optical measurement machine, however, will convert the 10 minutes to 10 seconds after the program is stored if there is a large batch of the same part.

Let’s think about one more thing: the profile projector is used for the initial batch inspection following the start of a new project or to confirm the accuracy of machines on the shop floor following re-calibration.

In this instance, the projector requires 30 minutes to complete the inspection as opposed to a piece of automatic optical equipment, which just needs 30 seconds. Production stops for the duration of that period.

What do you think a still production line would cost per hour?

Automated optical machines provide real-time data, allowing you to intervene and prevent costly production errors if parts are out of tolerance right away. Not only does this significantly reduce lead times, but it also ensures that you aren’t losing money on trash components and that you always provide what you promise to your clients.

Ever heard of industry 4.0?

Last but not least, the optical measurement machine collates digital data.

They can be linked to statistics software and the manufacturing execution system (MES), and they create excellent and thorough reports.

The optical measurement device can automatically correct the tools on your machines when it is fully integrated.

To conclude

Let’s wrap up by noting that a projector is still a suitable tool for tiny activities with consistent measurement by the same person, low frequencies, and flexible tolerance.

In high-volume settings, where customers demand traceability, where CNC machines are used, where batches are constantly changed, and where the work is concentrated on small and medium production series, optical measurement equipment excels.

Is there a solution everyone can agree with?

In my opinion. When addressing precise consumer requirements, there is no space for error in today’s industry. Time and precision are crucial; in order to attract new business and keep hold of current clients, you must constantly supply exact parts and exhibit complete capabilities, which can only be done through optical measurement.

If you want to know more, download the guide “Traditional systems and optical machines compared”.

Click on the following link Metrologically Speaking to read more such blogs on Metrology.