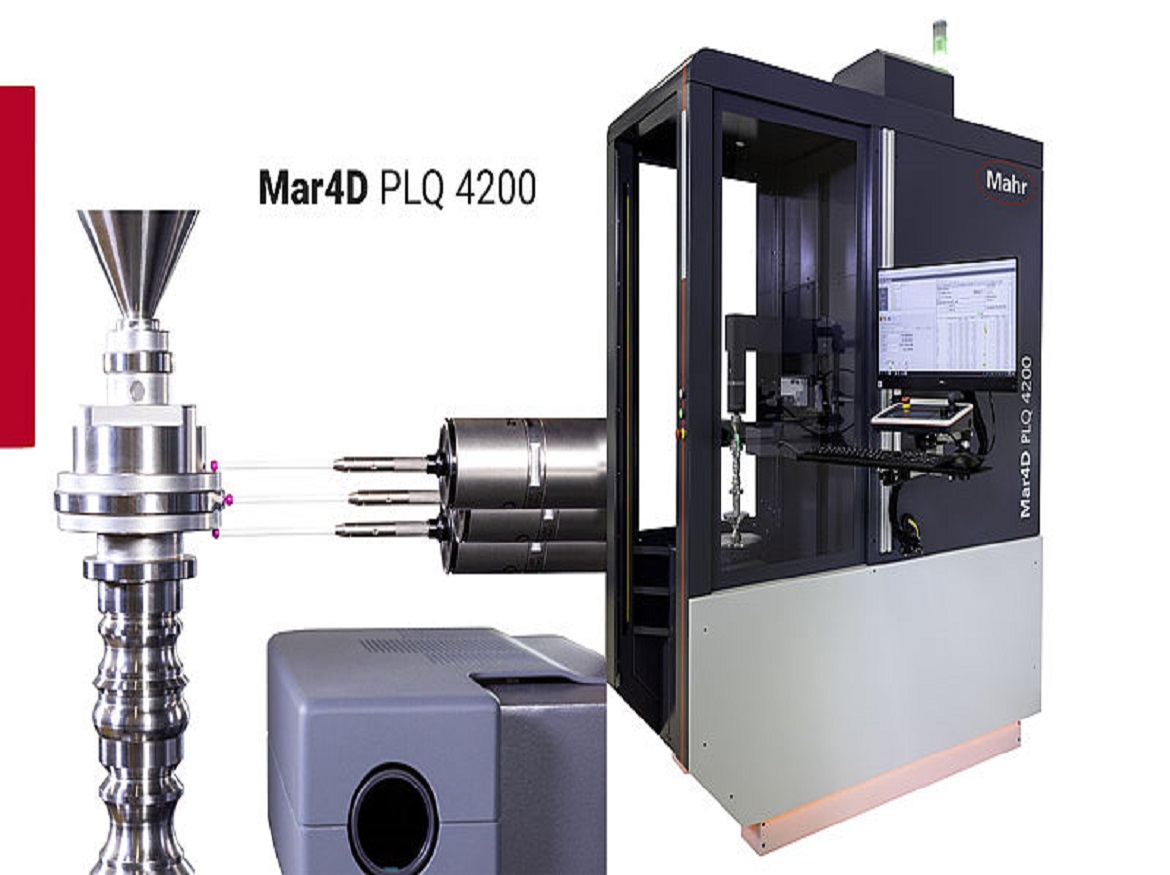

Mar4D PLQ 4200 product line for production and measuring room

The Mar4D PLQ 4200 solves various measuring tasks in a system that is as fast as possible, close to production, and reproducible as possible. The optical and tactile shaft measuring machine and traditional form tester technology are the only ones of their kind in the world. Increase your productivity in the production setting by taking advantage of the excellent features of the equipment and the extreme adaptability of the workpiece size.

Innovative dimensional metrology

Innovative dimensional metrology You can measure your rotationally symmetrical workpieces in production and the measuring room with the machines in the Mar4D PLQ 4200 product line. You will be persuaded by a variety of innovations and benefits:

Speed

- New control architecture and fast measurement technology

- High-resolution matrix camera & proven tactile probes.

Productivity

- Workpieces up to Ø 200 mm, length 1,000 mm, weight 50 kg

- Multisensor technology for a variety of different measuring tasks

Precision

- Integrated environmental controls for temperature and vibration

- Motorized tailstock with clamping force monitoring

Operator-friendliness

- Fast loading thanks to the light grid

- Interior monitoring to protect the machine

The new Mar4D PLQ 4200: Designed for your highest demands

The new PLQ 4200 from Mar4D: The Mar4D PLQ 4200 pursues a completely new concept that combines the best of different production metrology worlds. It is designed for your highest demands. The focus here is on speed, productivity, precision, and ease of use. You will be able to select the machine variant that best meets your specific measuring needs in the future.

Centering and tilting the table for even more measuring options

Centering and tilting table for additional measuring options One machine variant is the Mar4D PLQ 4200-T4, which comes equipped with a custom-designed, fully automatic centering and tilting table that symbolizes speed and precision:

It measures non-manufactured workpieces between centers and aligns them in the shortest amount of time with micrometer accuracy.

Alignment errors can be corrected using this method rather than relying solely on calculations. For instance, it only takes 30 seconds to correct an alignment error of 4 mm to 1 m.

The T7W tactile mold probing system, a three-jaw chuck, and the combination of centering and tilting table make internal measurements possible.

Utilizing the focusing and shifting table, the Mar4D PLQ-T4 can test similar highlights as an exemplary shape analyzer, for instance, hub runout.

For optical estimations, the focusing and shifting table guarantees that the grid camera can catch the edges of the workpiece considerably more precisely than with a simple numerical arrangement.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.