Why simulation is so important for building your quality inspection?

Better throughput

First, when metrologists program offline inspection tasks on complete simulated twins of their actual environment and equipment, the CMM or the robot are free to continue measuring and monitoring.

Improved efficiency

Second, when inspection programs have been simulated and virtually tested, they are error and collision-free once applied to the manufacturing process.

Faster programming & results interpretation

Third, an offline simulation program like Silma X4 or Silma X4 i-Robot can work directly with native or neutral CAD files and automatically interpret GD&T.

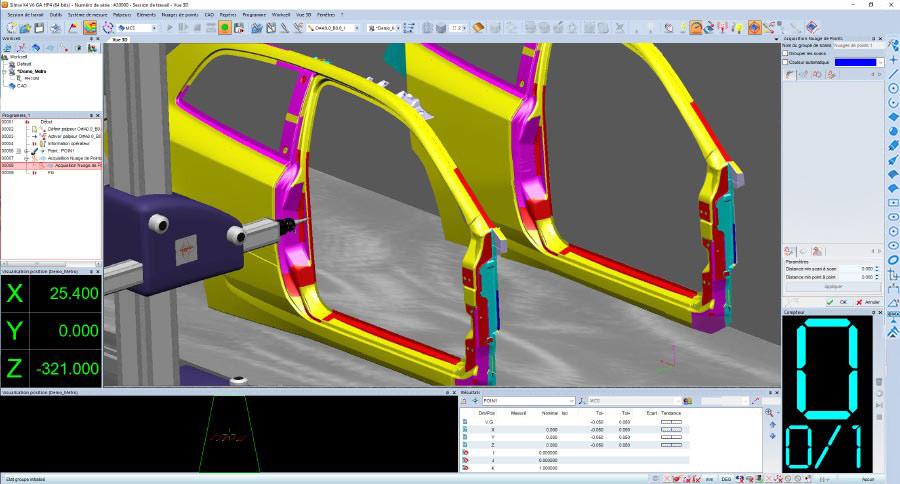

Silma is a powerful and compelling offline programming 3D inspection software dedicated for part programming and full offline simulation.

Unparalleled Virtual Programming Software

Silma is the advanced offline programming 3D inspection software dedicated for part programming and full offline simulation. This complete offline solution provides the integration of all real-world components into the virtual world.

Silma consumes digital data from engineering allowing inspection programs to be created and validated even before the first part appears on the manufacturing line.

Currently, two versions of the software are available, both offering significant advantages:

- Silma X4 dedicated for CMM offline programming and 3D measurement simulation

- Silma X4 i-Robot, designed for measuring robots directly on, or just beside the production line.

Using Silma, you can:

- Program all of your CMM using one software, independent of machine size, brand or configuration,

- Simulate the measurement workflow and detect collisions using a virtual CMM environment that exactly represents your CMM, parts and fixtures,

- Prepare your inspection reports without using your online software,

- Perform post inspection analysis including report generation, best-fit analysis and additional GD&T evaluations.

On the other side, Silma X4 i-Robot, allows you to fully line up both measuring and robotic equipment by programing accurately and without the risk of collisions, prior to the production cycles. It paves the way for automated inspection.

Offline programming solutions that pay off

Silma is used to simulate existing measurement programs, as well as creating new ones using the CAD file. All without machine downtime. No additional know-how is required; reality merges with virtual reality to create the impression of sitting in front of a machine and enables drive further intelligent action back into the physical world. Silma sets the standard for all other software to aspire to.

1/ Definition phase

Silma X4 is a time saver as it takes over the cost-intensive work cell and virtual environment definition: scanning, self-centering, rotary tables, tool changers can all be realized offline. Besides this, commonly available robots or CMMs, detailed probe heads, probes, styli and accessories from the extensive CMM library are right at your fingertips. We support all commonly available brands: Wenzel, Zeiss, Leitz, Mitutoyo, Hexagon, API, Creaform, Faro, Kreon, Leica, Mora, Nikon, Renishaw and so many more… Still having a doubt? Then check with us!

2/ Reduced part programming capacity

The virtual measuring machine is even more convenient and quick to operate thanks to smart algorithm that lies within the Inspection Path Planning (IPP) module. Instead of programming a whole measurement routine- only a click-away – Silma computes the best measurement trajectory, with:

- Automatic head orientation

- Automatic obstacle avoidance

- Optimized path, with minimum crossing points – smart and fast,

independent of type of probe, be it touch or optical.

3/ Offline programming

Not only can you create and simulate part programs with Silma, but also it entirely validates and troubleshoots them using advanced probing and measurement routines. Based on a programmer-orientated and user-friendly interface, part program proofing is fast and easy.

4/ Part program validation

Having doubts about part program validation? Do not worry anymore; program consistency is validated thanks to a genuine 3D inspection and analysis engine. In addition to collision detection, automatic obstacle avoidance gives you the overview, and possibility to optimize your entire probing path.

5/ Part program execution

You can send the program to the machine virtually, error- and collision-free!

Support manufacturing with simulation and digital twins and witness improved understanding of potential bottlenecks, enhanced quality control and measurement automation.

For more information, please visit https://www.metrologicgroup.com/digital-twin-simulation/