A workflow automation solution from Magics is unveiled, along with a connection with the CO-AM software platform and Materialise Machine Manager.

New features for Magics, the top software for data and build preparation, have been announced by Materialise, a major global provider of software and services solutions for 3D printing. The digital manufacturing process connects every step of the production process, from product design through component and construction planning to printing. Connectivity and traceability are essential to making this possible, which is why the most recent Magics version emphasizes linkages with other software solutions.

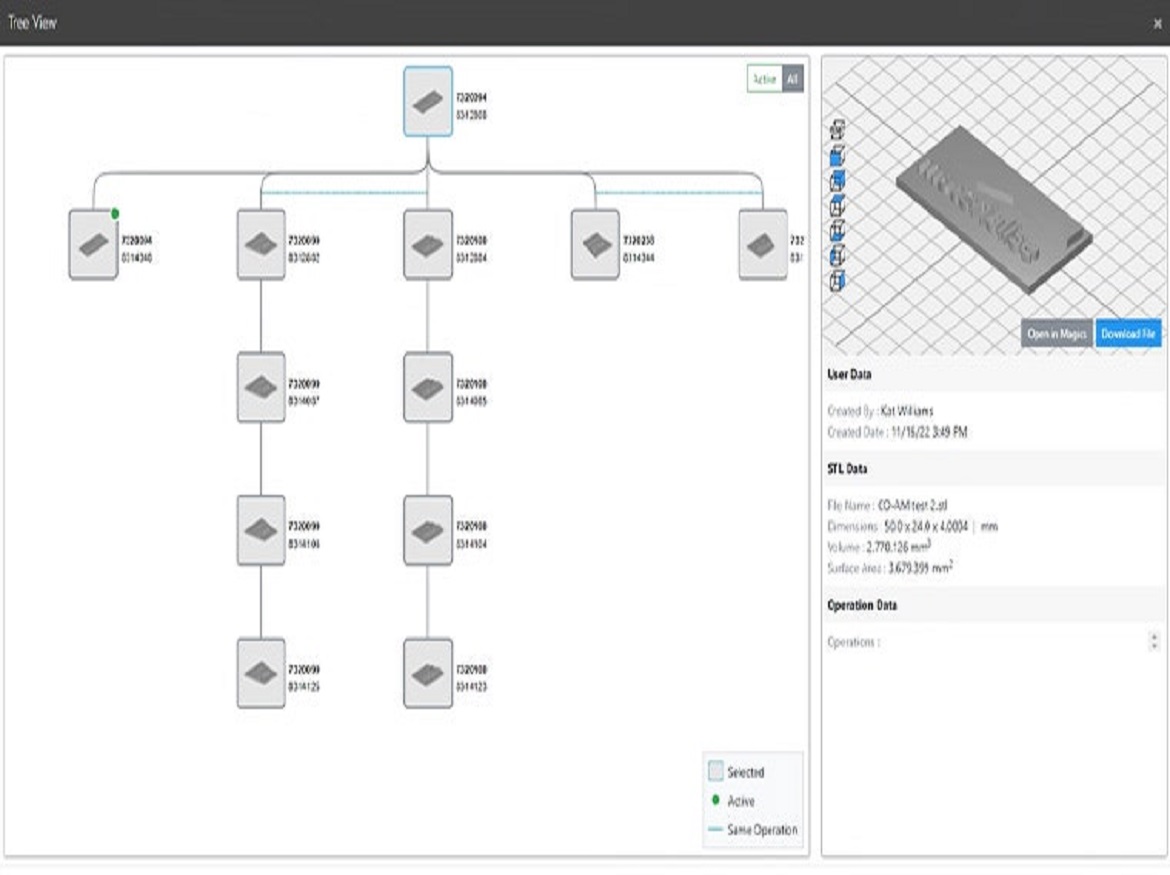

A revision tree created by Magics’ interface with CO-AM offers traceability to the 3D printing process by recording each action made on a part or build, along with the user who carried it out. For tracking part status from start to finish, a connection between data, prebuild software, and production execution systems are essential, but it is frequently absent due to software solution silos.

Egwin Bovyn, Product Line Manager at Materialise, asserts that traceability is essential to any 3D printing process. In addition to being necessary for highly regulated industries like aerospace, it also contributes significantly to quality improvement. Users can gain insight into what went well and poorly by tracking the parameters of previous creations. You receive a thorough log that they can use to tweak their procedures.

This update also adds interaction between Magics and Materialise Machine Manager, allowing users to submit project data and build settings to their Build Processors.

According to Brecht Pellens, Product Manager at Materialise, “By integrating Magics with our Machine Manager, we offer a new cloud-based solution for managing your AM machine park and the connected Build Processors.” Users no longer need to rely on a single workstation for entire build preparation, making file sharing and processing parameters with coworkers easier than before. This is because cloud-based working is intrinsically more collaborative. Additionally, all build files and processing parameters are now maintained on the cloud, further enhancing workflow traceability.

One further notable aspect of the Magics update is the first completed workflow automation script. A Magics feature called Workflow Automation allows users to automate repetitive workflows during the preparation of data and builds using ready-to-use and bespoke scripts that Materialise or the user has created. Smart Labelling, the first ready-to-use script, was created for Protolabs and quickly and automatically labels parts. Throughout the year, more workflow automation scripts will be made accessible. “With our new automated system, it takes one worker maybe five minutes to label twenty pieces. For two individuals, it used to take an hour to two hours. It was not a fun job.

Between May 2 and 4, Materialise will exhibit its CO-AM and Magics technologies at the RAPID+TCT conference in Chicago at booth 4830.

Credits: Materialise

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.