Do you know the exact measurements for a huge boat? How does measuring a boat using 3D scanning help? How can you optimize the creation of your products?

Manufacturers must continuously upgrade their products to satisfy shifting demand if they want to succeed in this fiercely competitive market. It is also crucial to make use of technology and data to improve workflows and product development processes.

3D Scanning for Product Development

In order to create cutting-edge products, shipbuilders must maximize their product development. However, it is also difficult, time-consuming, and expensive, particularly when working with sophisticated items that have exacting features and high requirements for quality.

Here, 3D scanning can be useful. Using lasers, 3D laser scanning is a method that creates digital models of real-world things by capturing their geometry. It can be used for many different jobs during the product development process, such as design and prototyping.

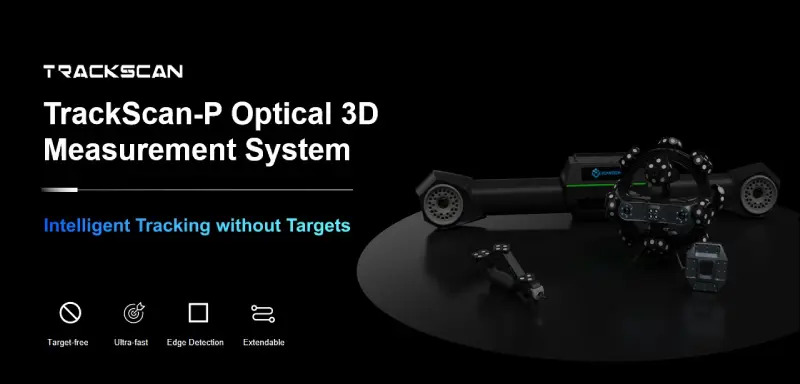

Large ships and boats can be scanned with Scantech’s 3D scanners, such as the professional and composite KSCAN-Magic and optical tracking TrackScan-P models.

Scan a Boat with KSCAN to Enhance Product Development

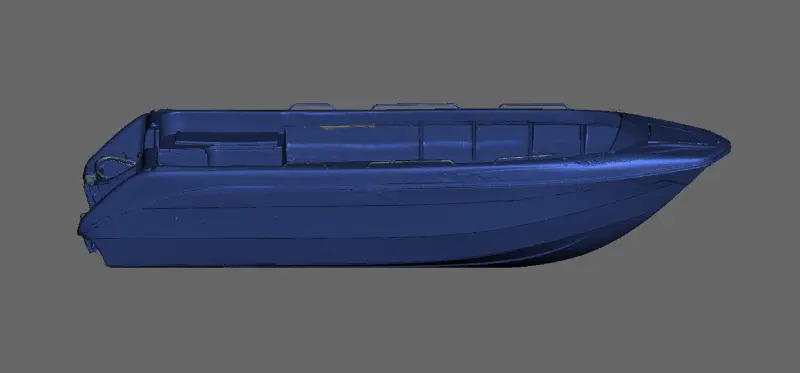

A company called Healthport provides customers with complete solutions for any major business problem they may be facing, including ideation, strategy development, and execution. The customer wanted to reverse engineer the boat using the CAD files.

The boat was about 12 meters long, 5 meters wide, and 2 meters high. The yacht was intricately shaped, with many difficult-to-reach curves. On the outside, it had lacquered and reflective surfaces.

Great Master, a Scantech reseller, employed the expert 3D scanner KSCAN-Magic to collect the yacht’s 3D data. The many scanning modes it offered satisfied the clients’ individual needs. Overall precision was assured by the integrated photogrammetry in KSCAN Magic.

The data was efficiently and swiftly captured with the aid of its large-area scanning mode (infrared laser). Its deep-hole scanning mode (single blue laser) did well in capturing details when scanning the dead corners or difficult-to-reach locations. The reflective metal pieces were quickly scanned using the fast scanning mode (blue laser crosses) without the use of powder.

Benefits of 3D Scanning

The client obtained a full scan of the inner and outer sides of the yacht.

Efficient Measurement

The yacht was huge, thus using conventional measurement methods to get its data took a lot of time. The KSCAN scanner completed the measurement quickly and successfully performed 3D scanning.

On-site Measurement

In the past, users had to prepare the measurement area and move the boat with the use of large machinery.

However, Scantech’s KSCAN-Magic performed on-site measurements due to its reliable algorithm and portability. The yacht’s top and bottom were both taken captive.

Precise Measurement for Narrow Spaces

It was difficult to 3D scan the enormous boat’s tight compartments due to the poor visibility and accessibility. The KSCAN-Magic has a small size and a slanted viewing angle. It made it possible to measure 3D data accurately and without losing any information while working in confined locations.

Built-in Photogrammetry

Over a given distance, the scanning errors on a large-scale object tend to get worse. By using broad scanning regions and multi-angle positioning to more precisely align the scans, photogrammetry can help eliminate these mistakes.

The advantage of KSCAN-Magic’s combination of photogrammetry and laser scanning technology is that it can maintain consistent accuracy even for huge portions.

Scan a Boat with TrackScan to Facilitate Product Development

Since 1985, Rodosto Marin has been a licensed service provider in the sales of rowboats, motorized boats, and yachts, non-motorized sailboats used for recreational and athletic activities, and other maritime vehicles & accessories.

Due to the high cost of research and development, new products are exceedingly expensive to produce. By using 3D scanning, Scantech’s distributor Polygon Engineering helped the company accelerate the creation of a large boat.

The engineer constructed new boats in accordance with the CAD models he made from existing boats using 3D laser scanners to speed up product development. Designers may be able to more accurately record the 3D data of their initial ideas with 3D scanning and investigate several design alternatives.

3D Scanning Boats

The boats are 460 cm and 520 cm long, and 190 cm and 210 cm wide, respectively.

A boat is difficult to scan because of its size and shape. When the user has a deadline to meet, the work is significantly more difficult. In this instance, the business wanted a thorough mapping of the boat to create a new product.

The engineer swiftly obtained STL data for the wide and bulky components of the boats using Scantech’s TrackScan-P optical 3D system, and for the tight places inside the boats, he used a small SIMSCAN 3D scanner.

Benefits of Optical Tracking 3D Measurement

The engineer was able to perform dynamic, ultra-high accuracy 3D measurements without markers thanks to Scantech’s TrackScan-P. It was simple to carry out flexible contact measurements and give high-precision 3D data when connected with a portable CMM T-Probe.

Scantech’s experienced 3D laser scanners and the user’s knowledge allowed for an effective scan of the yacht. In under 1.5 hours, they scanned two different boat types. (Thanks to Scantech, costs can be cut by up to 90%)

For product development initiatives, scanning data and the solid model were both utilized. The new 580 models, it was intended to strengthen the chassis structure and functionality of the boat. By removing the need for manual measurements and trial-and-error, high-precision 3D scanning conserved time and resources.

Summary

Product development can gain from 3D scanning in a number of ways. Complex forms can be created and altered, the design process can be sped up, prices and risks can be reduced, and quality and customer satisfaction can be raised.

Therefore, by offering unique and high-quality items, producers can acquire a competitive advantage in the market.

Credits: 3D Scantech

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.