The hardware solution for optimized image quality

The ZEISS scatterControl module significantly enhances the quality of CT scan images and minimizes scatter artifacts. The subsequent data handling and evaluation steps for suitable parts are made easier by these enhancements, making the surface determination and defect analysis even more precise. Even steel inlays, additively manufactured metal parts and aluminum cast parts, as well as other assemblies made of denser materials, work well with the product.

The module is available for the ZEISS METROTOM 1500 225kV G3 as an upgrade or as part of a new system purchase. Now is the time to upgrade your system with ZEISS scatterControl, which will give you better image quality and make data evaluation much simpler.

How you benefit from ZEISS scatterControl

Better image quality, better defect detection

By reducing scattered radiation artifacts, ZEISS scatterControl significantly enhances CT image quality. Defect detection is made easier and there is more contrast between the various components: It is now possible to evaluate portions that were previously nearly impossible to evaluate.

Improved surface determination

Imperfection recognition, yet the general nature of surface assurance benefits from ZEISS scatterControl. For metrology applications on difficult parts, where artifacts distract the surface determination process if they are not corrected, this is a significant advantage.

Fast scanning with VAST mode

VAST and “Stop and Go” scanning modes are supported by ZEISS scatterControl. Cone-beam CT image quality is comparable to that of fan-beam CT with the scatterControl solution, but scanning times are up to 1000 times faster.

Easy to use

One-click is all it takes to use ZEISS scatterControl. The module is fully integrated into the software and seamlessly integrates with other useful METROTOM OS features like VHD (Virtual Horizontal Detector Extension), AMMAR (Advanced Mixed Material Artifact Reduction), and VolumeMerge.

ZEISS scatterControl for better defect analysis

For a variety of parts and industries, the image quality of CT scans is significantly enhanced by ZEISS scatterControl. That makes ZEISS scatterControl the best option for a number of obvious reasons, including the module’s position in relation to the workpiece and effective artifact removal. Below, learn how to use the module for outstanding defect analysis and detection.

Reduced artifacts for improved CT image quality

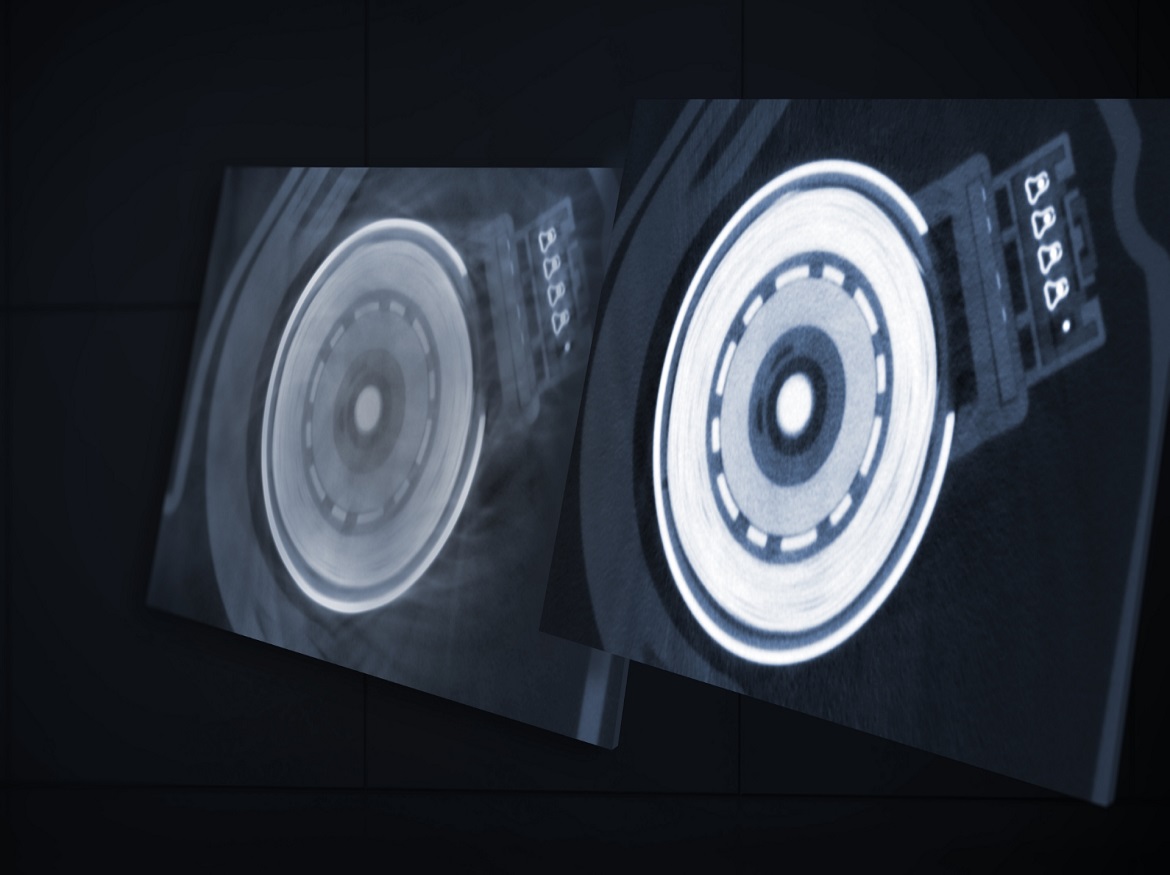

ZEISS scatterControl makes a significant distinction. Compare the X-ray image quality that can be achieved with and without the scatterControl module by utilizing the slider element. The improved image has greater contrast and fewer artifacts, making it much easier to see details.

Superior quality due to module positioning

ZEISS scatterControl accomplishes better quality contrasted than comparative items due with the functioning guideline of the module: It is situated in between the detector and the tube. The module can be positioned in front of smaller objects, such as dense additively manufactured parts, and behind larger objects. It works one way or the other. Additionally, the sophisticated collision prediction software and the in-built physical collision sensor effectively prevent collisions.

Ideal for a range of parts and industries

- Foundry: Massive aluminum or magnesium parts, even with steel inlays

- Automotive: Castings with steel inlays, power electronics

- Additive manufacturing: Dense, metal-printed parts

Improved 3D inspection

Enhancements for the volume of information bring about a lot more straightforward assessment. 3D surfaces are not entirely set in stone and are delivered without diverting antiquities. Most of the time, scattered radiation causes artifacts like 3D pseudo surfaces that make it hard to take accurate measurements.

Reliable evaluations software for X-ray inspection

For injection-molded, medical, additively manufactured, and other components, the ZEISS Automated Defect Detection (ZADD) software consistently detects even the tiniest flaws.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.