Before learning something about 3D laser Scanning, maybe we need to know what is a 3D scan first. 3D scanning is a technology that captures the three-dimensional shape and appearance of physical objects or environments using various scanning methods and sensors.

It creates a digital representation of the scanned object, which can then be used for various purposes, such as reverse engineering, 3D inspection, product development, visualization, and more.

3D scanning is widely used in industries like aerospace, automotive, mold, energy and heavy industry, architecture, healthcare, entertainment, and archaeology, among others.

What is Laser Scanning?

3D laser scanning is a specific type of 3D scanning technology that employs lasers to measure distances and create a highly accurate and detailed 3D representation of objects or spaces.

How Does Laser Scanning Work

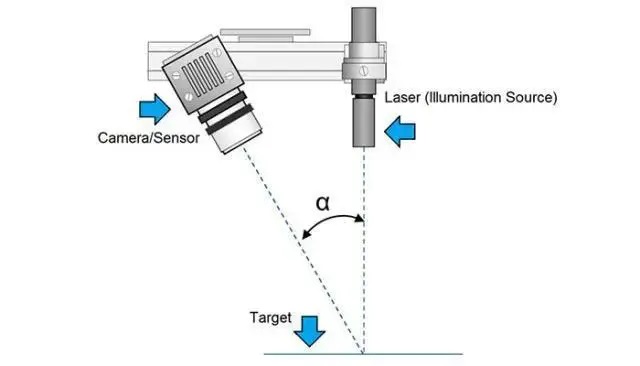

SCANTECH 3D Laser scanners are based on laser triangulation 3D scanning technology, a method for determining the three-dimensional coordinates of points on the surface of an object by measuring angles and distances.

This process is fundamental to creating detailed 3D models of objects or environments, and it’s based on Here’s a step-by-step explanation of how a laser scanner employing laser triangulation typically works:

Laser Emission: The laser scanner emits a laser beam, which is often in the form of a line or a pattern, onto the object or surface to be scanned. This emitted laser light serves as a reference.

Laser Reflection: When the laser beam interacts with the object’s surface, it reflects back towards the scanner.

Sensor/Camera Capture: A sensor or camera in the scanner captures an image of the reflected laser light. In the case of structured light scanners, such as those using laser triangulation, this image typically shows the laser line or pattern as distorted due to the object’s shape.

Analysis: The scanner’s software such as ScanViewer analyzes the distortion of or pattern in the captured image. By measuring how this pattern deviates from its original shape, the software calculates the 3D coordinates (X, Y, Z) of various points on the object’s surface.

Multiple Scans: To create a comprehensive 3D model, the laser scanner typically captures multiple scans from various angles or positions. Each scan contributes data points to build a detailed point cloud, which represents the object’s 3D surface.

Point Cloud Integration: The individual point clouds from each scan are aligned and integrated to create a complete 3D model of the object or environment. This integration process often involves matching common features or reference points between scans to accurately combine the data.

Surface Reconstruction: The point cloud data can be further processed to create a surface mesh or a solid 3D model that accurately represents the object’s shape.

Data Output: The resulting 3D model can be output in various formats, such as STL, OBJ, or point cloud formats, depending on the intended application.

Advantages of Laser Scanning:

High Precision:

Scantech 3D laser scanning provides high levels of accuracy and precision in capturing 3D data, making it suitable for applications that require detailed measurements.

High Speed:

Scantech 3D laser scanners can capture a large amount of data quickly, allowing for rapid data acquisition.

Non-Contact:

Scantech 3D laser scanning is a non-contact method, allowing for the measurement and documentation of objects without physical contact, which is crucial for fragile or sensitive objects.

Detailed 3D Models:

3D laser scanning with triangulation technology produces detailed and comprehensive 3D models that can be used for a wide range of purposes across various industries.

Versatility:

Laser scanning can be used in various industries, including engineering, architecture, construction, archaeology, and more.

Overall, Scantech 3D laser scanning is a powerful tool for capturing and digitizing real-world objects and environments with precision and detail, making it valuable for a wide range of applications.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.