When considering the makeup of national economies, especially those that comprise the G20 —a cohort that includes the European Union, Australia, and 18 additional member states — it’s easy to envision giant service sectors and a hyper dependence on information technology systems.

And while true to an extent, such generalizations fail to appreciate the value of older, more industrial sectors, like mining, for instance, that are just as vital to a country’s economic output. In Australia, for instance, it is the nation’s powerhouse GDP driver and in just the last few months the sector has vaulted to pole position at 10% of the country’s entire economic output, the largest single piece of the nation’s $1.3 trillion economy.

In fact, mining and energy exports alone are on pace for a record $310 billion this financial year and iron ore, the largest commodity within the mining sector, saw its price rise in June to a record $230 per metric ton. This is despite a slowdown in coal exports due to the pandemic as well as long term changes in energy consumption as the world shifts away from fossil fuels.

Thanks in part to the strength of this one sector (a sector which directly employs 261,900 and 1.2 million in indirect jobs total) the Australian economy only contracted 0.2% in 2020. As one might expect, keeping an industry as vital as this in top working order is of paramount concern. After all, the mining industry can’t thrive if its cone crushers, drill bits and transport crawlers don’t measure up. Thus, ensuring the continued viability of mining industry equipment, while reducing/eliminating downtime and improving operational performance, costs and safety, cutting costs, is the responsibility of companies, such as, like Bradken®, a century-old global manufacturer and supplier of differentiated consumable and capital products to the mining, transport, general industrial and contract manufacturing markets.

Digging Deep, With Precision

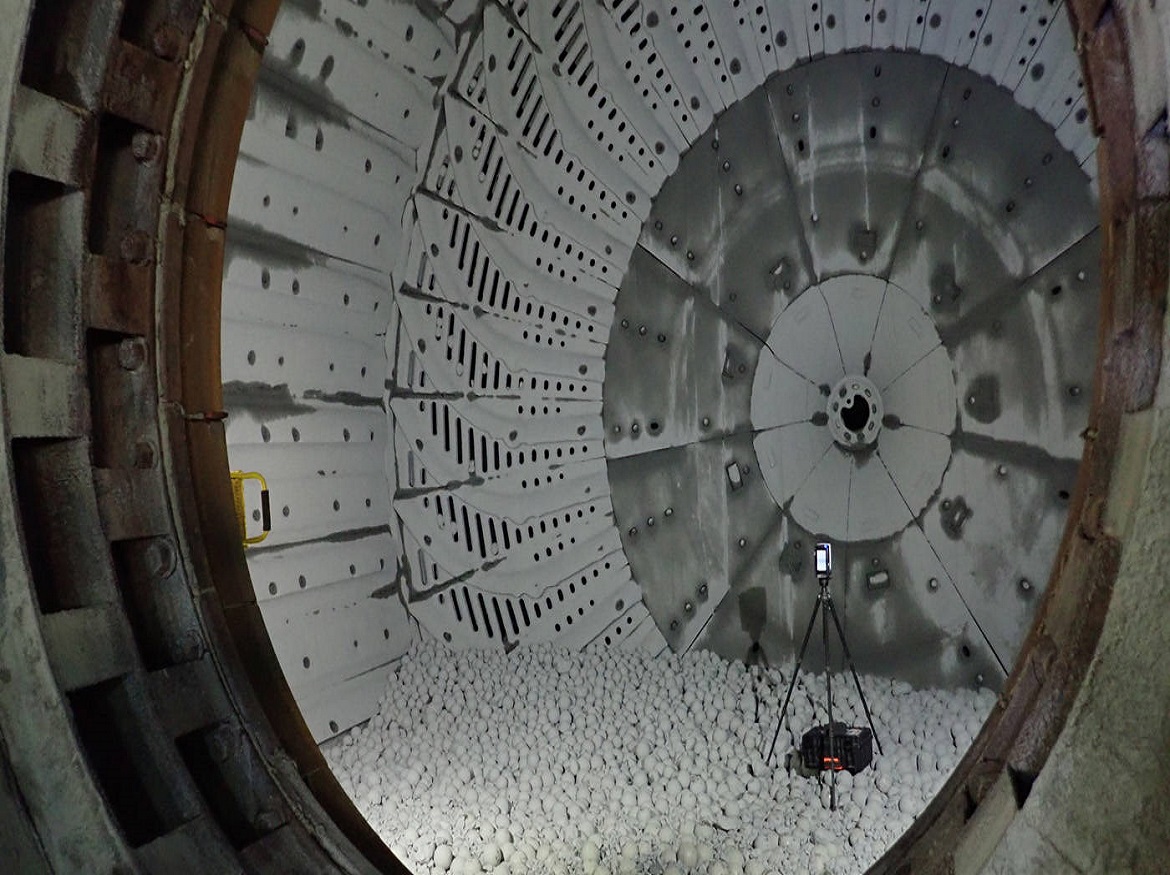

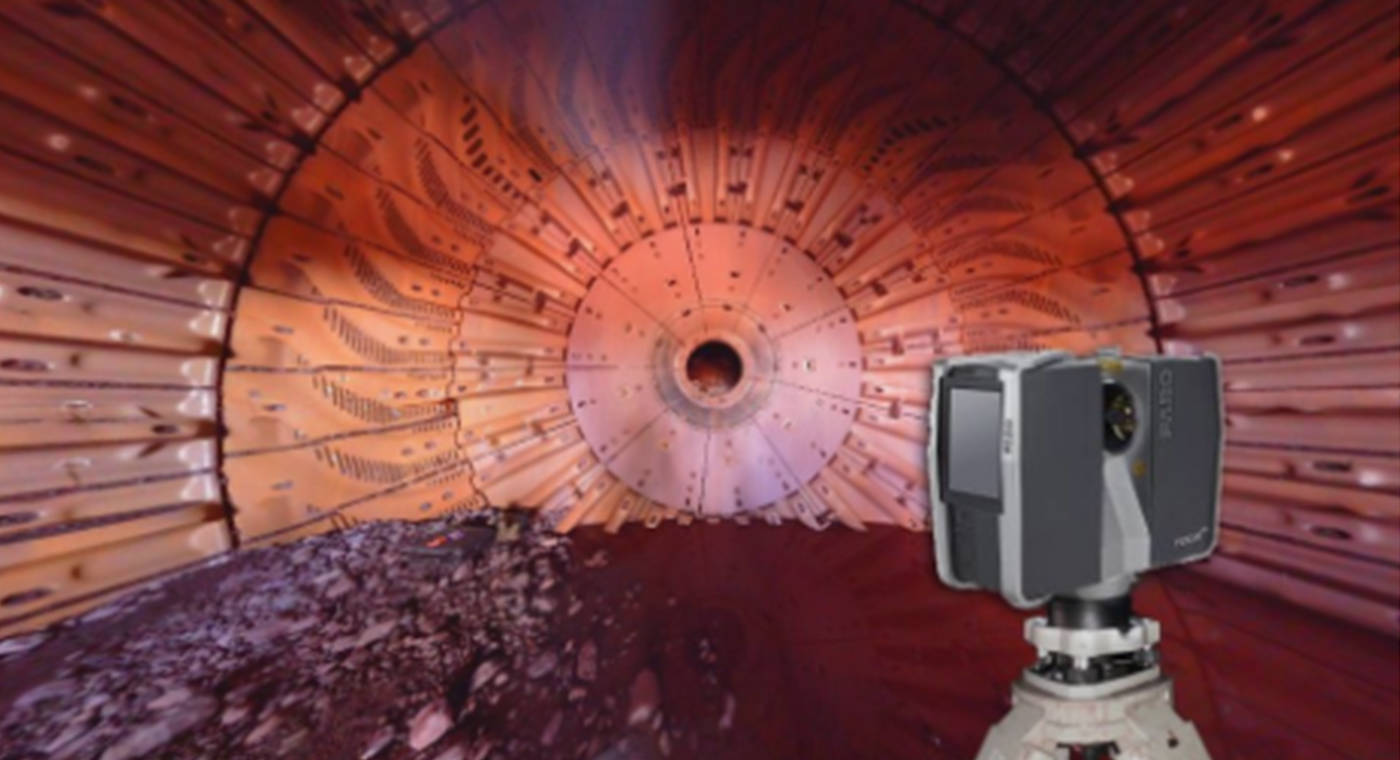

For the last nine of those 100 years, Bradken has relied on up to 20 FARO® Focus Laser Scanners to assist in the company’s wear monitoring and data reporting of mill liners — the protective overlay which shields a mining grinding mill from some of the abrasive and thermal forces generated during the milling (or grinding/pulverizing) of extracted hard rock and metals (namely gold, copper and iron-ore) — thereby extending the life of the mill itself. Recently Vijay Gandhi, the Platform Lead at Bradken, explained how FARO’s advanced 3D laser scanner technology, along with its FARO SCENE Software, can scan the working parts of today’s most sophisticated mining equipment. The goal is simple but essential: to determine if parts have gone out of tolerance. And later, register the point clouds the Focus Laser Scanner generates to create detailed 3D visualizations of the milling machines grinding mills and their protective liners with the ability to export that data in various formats. Done right, these wear monitoring reports lead to improved mill liner designs, greatly boost the efficiency and timesaving their clients enjoy around the world.

“Technically you’re performing laser scans to achieve faster data capture and to minimize human intervention, where personnel must manually measure the liners themselves,” Gandhi said. “While not totally automated – you need to set up the scanner, it goes for around 8-10 minutes — once you’re happy with the data you can pack up and move on to another site.”

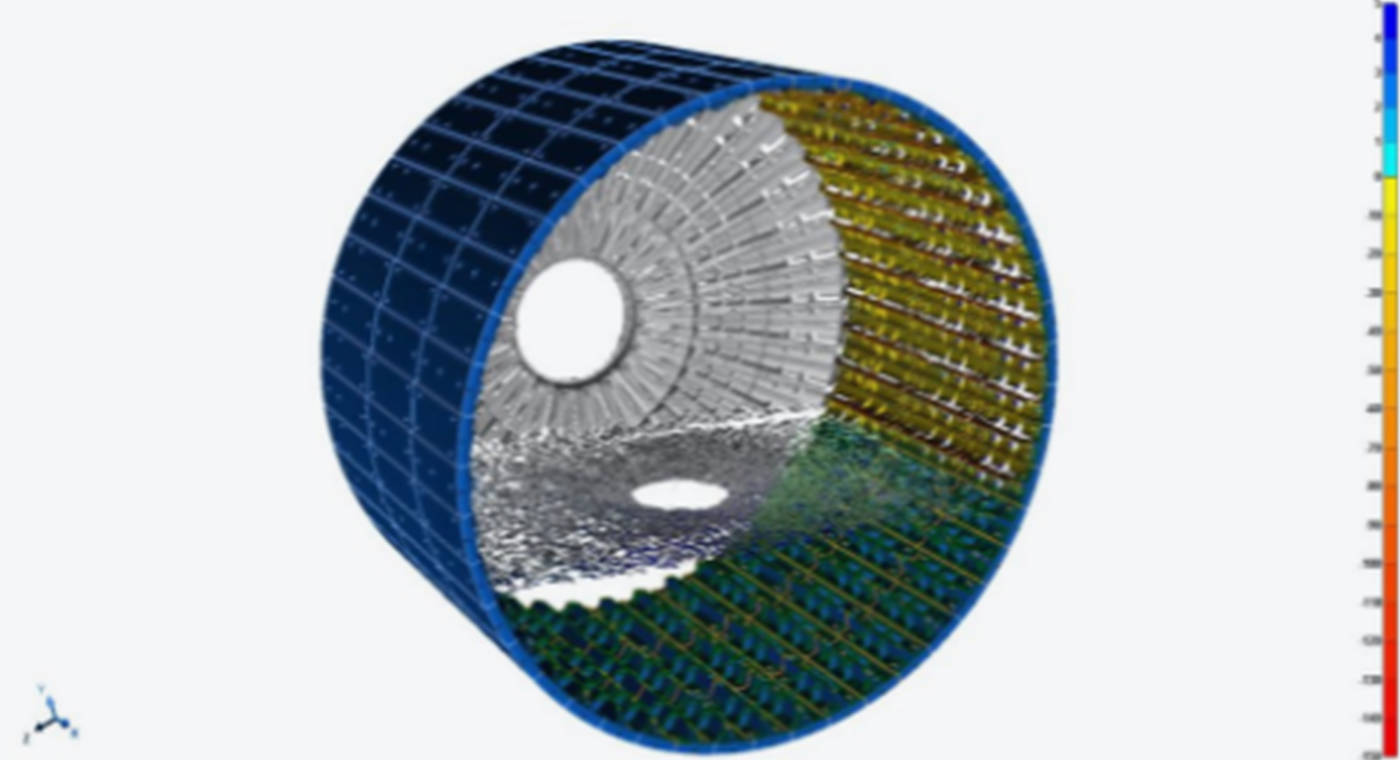

The Focus is the capstone 3D measuring tool of a suite of products Bradken employs as part of its branded Vision Insight™ system for fixed plant mineral processing. By providing an in-house service that relies on both ultrasonic and 3D laser scanning, Bradken can generate accurate wear plot imaging and liner profiles, as well as predict a mill liner’s longevity of service. It works like this: the system captures a 3D modeling of the mill liners and records the variation between new and worn conditions, including liner shape, profiles and thickness. The data is then used to record the wear rates across the liner system, identify the high wear zones (with heat mapping) and predict the mill liner life, and mill liner change and failure dates of each liner within the mill.

Presentation Power, Application Potential

Once collected and registered in 3D point cloud software, the data is presented in an intuitive and easy-to-read dashboard format, which provides percentage readout of the life remaining in a specific part. Then, mill operators and maintenance staff use the report to better plan future liner upgrades, reducing overall maintenance costs. Additionally, color imaging from the 3D scan provides a clear representation of the interior of the entire mill. Last, the 3D data is fed into Bradken’s 3D DEM software to simulate grinding mill performance with the goal to assist in future liner design enhancements, innovations and general liner development.

When it comes to overall efficiency and timesaving however, Gandhi is quick to point out that while a manual liner part inspection might take 10-15 minutes versus 8-10 minutes per laser scan, only about a 20-30 percent reduction, what’s most import is the granularity of the data collected within that time span under same number of people, in similar location.

“In the pre-Focus days we’d have to measure part by part; of course, we weren’t measuring the hundreds of components assembled, but by introducing a 3D laser scanner, with the same amount of time, the amount of data captured is huge,” he said. “If you perform the inspection manually, measuring each component, you would select one item and we assume that it’s the same measurement across all the components installed in that same set. Whereas with the Focus we can capture everything at the same time, provide a visual record and we can do much more detailed analysis back in the office.”

Thanks to this adaptability, Bradken now sees broadening use potential for FARO solutions, specifically as it relates to reverse engineering and long-term archiving of collected digital data. For parts and component comparisons made several years apart, documenting any changes, even the most minute, is essential when gauging its safety and repeat reliability. As a result of developments like this, the Focus is being put to good use scanning the undercarriage components of excavating vehicles, proving once again that with a FARO Focus Laser Scanner at the center of a company’s data collection, storage and analysis success, Bradken — or any brand looking to make the investment — will have the “metal” to achieve growth and new business success they never dreamed possible.

That’s true for the Bradkens of the world, and their many customers.

“The main intent of Vision Insight™, which includes FARO’s 3D laser scanning hardware and software technology, is to give the condition monitoring of that asset to the client which helps them optimize the operations performance,” Gandhi added. “For the client, this helps in planning their periodic maintenance and it also helps Bradken improve designs and the end user schedule their future orderings. It’s a value-added service for Bradken and it’s a win-win for both parties.”

Click on the following link Metrologically Speaking to read more such case studies about the Metrology Industry.