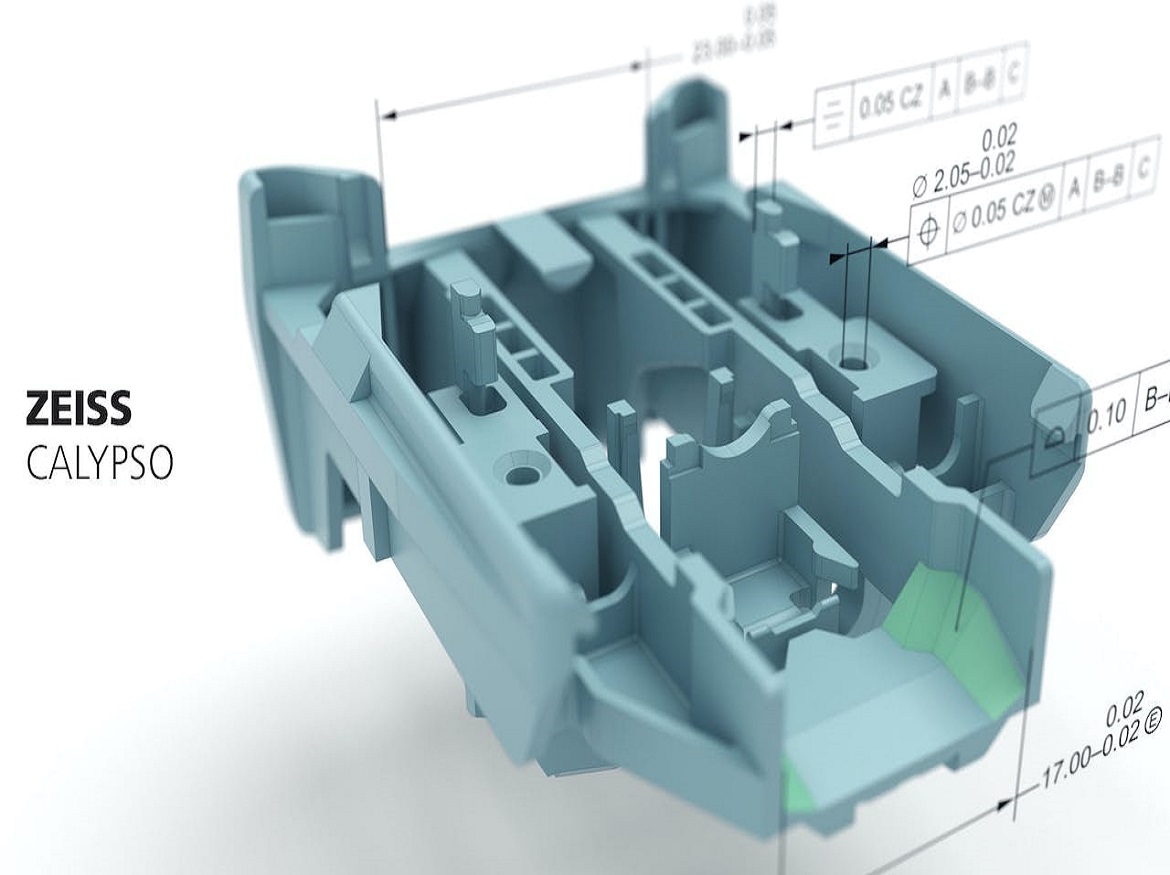

Many businesses are committed to quality control, for instance by using coordinate measuring machines, in order to keep their position as the market leader. However, a thorough and unique evaluation is only made possible by ideal software. The general measuring programme, known as ZEISS CALYPSO, enables 3D data verification and analysis, as well as tactile and optical measurements using ZEISS, coordinate measuring equipment. The updated programme has been made available.

“This year, our main emphasis is on performance-related features. Together with our customers, we have expanded the capabilities of ZEISS CALYPSO, says Christoph Grieser, head of global software sales at ZEISS Industrial Quality Solutions. The advantages of ZEISS CALYPSO 2023 include enhanced fault analysis, improved optical coordinate measuring machine (CMM) processes, greater usability, and upgraded GD&T evaluations in accordance with ISO-GPS and ASME.

New mathematics for GD&T

The software now provides updated algorithms for evaluation in accordance with several standards, including ISO-GPS and ASME, to further optimise GD&T evaluations for ZEISS CALYPSO users. As a result, by employing this technique, users can work with Geometric Dimensioning and Tolerancing much more effectively and gain the advantages of quality control.

Improved fault analysis

Despite the increasing speed of optical coordinate measuring devices, the typical evaluation of measurement findings is still a labour-intensive, frequently manual procedure that calls for some level of knowledge. The automated fault analysis ZEISS CALYPSO concept ensures automation of the entire evaluation process, saving the user important time. The programme dynamically identifies problems in the testing feature and then automatically presents all the pertinent information in detail. The user is not required to invest significant time in preparing reports. The release this year gives an even better-automated fault analysis: An interactive report automatically displays every fault. Every detail is now visible in enhanced automated plots, and dynamic zooming in an interactive report opens up new possibilities for various electronic devices as well as minor mechanical parts.

Optimized workflow with optical CMMs

In addition, ZEISS CALYPSO now offers new assessment features for coordinate measurement systems like ZEISS O-DETECT. For instance, the user can automatically search for geometrical elements in the captured image or use the overview camera for navigation.

Committed to usability

ZEISS likewise hopes to establish the standard with the most recent CALYPSO edition. The ZEISS professionals, however, are even more dedicated to working with the clients. “Usability is crucial to both us and our consumers. We concentrate on the difficulties that they experience every day. We wanted to develop ZEISS CALYPSO so that we could process large amounts of data quickly, securely, and intelligently,” Reich says. For instance, the new toolbox cuts down on the number of working steps. In a unique toolbox, frequently used testing features can be saved as favourites.

A significant premium is placed on individualization; users can adapt ZEISS CALYPSO specifically to their requirements by, for instance, integrating CALYPSO freeform or CALYPSO curve, which provides a wide range of extra possibilities.

“We update and improve our software constantly. Additionally, we incorporate new functionalities into our software because new applications constantly create a demand for them. To be a dependable partner to our consumers is our overarching purpose, says Grieser.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.