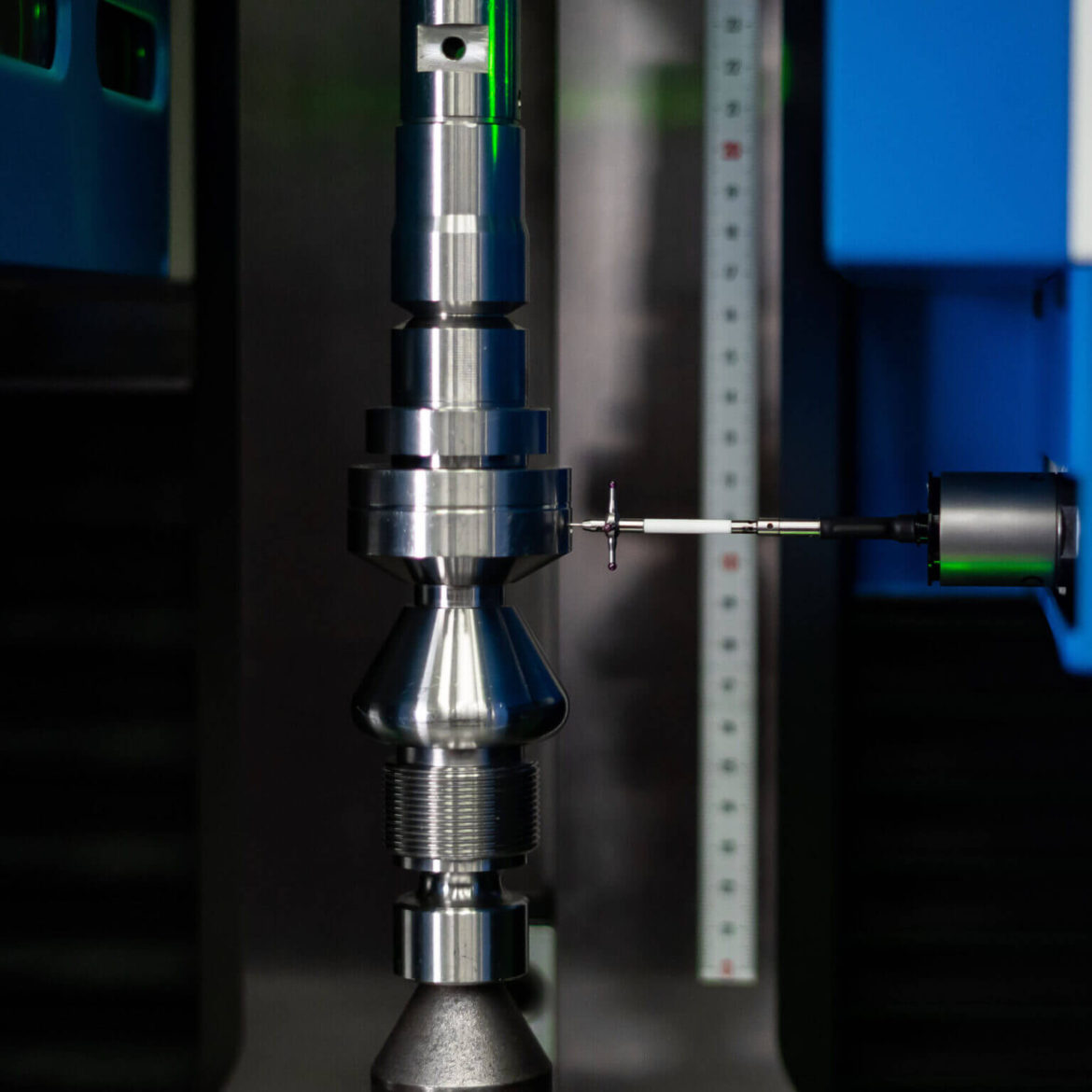

Industrial metrology specialist, the Sempre Group, introduces the new Opticline T3D optical shaft measuring system, now supplied with tactile 3D measuring probe. The technology, manufactured and designed by partner Jenoptik, is ideal for the measurement of axial run-out, grooves and bores for shaft-based parts with milled or drilled features. Alongside its high speed, optical and non-contact measurement options, the T3D probe allows the user to achieve full component measurement with just one system.

Manufacturers can easily integrate the Opticline T3D gauging system into their process to help reduce production cycle times. It is designed to be used directly on the shop floor, right next to CNC machines,but can also be used in inspection laboratories. The Opticline is a market leading technology that guarantees accuracies of 1 micron and is tested to meet EN ISO 10360 standards. It also offers major speed benefits, as it can reduce the time to measure parts from hours or minutes to just seconds.

The Tolaris measurement interface software for use on the platform is intuitive and user-friendly with features that make programming, operation and reporting straightforward. For example, it includes wizards for set up and a live mode for direct feedback when creating test plans. Manufacturers can also benefit from fast and reliable analysis of results and customisable reports. Alongside the inbuilt wizard, Sempre offers comprehensive training packages for all levels of operator, from basic operation to advanced programming.

“Small features, like chamfers and radii, have historically been hard to measure,” explained Mike John, managing director of Sempre Group. “The Opticline measures these difficult features at sub-micron level, directly on the shop floor. The new T3D probe adds the ability to measure internal dimensions, meaning just one system is needed for a comprehensive measurement.

“Opticline users can realise up to a 40 per cent reduction in time per measurement,” added John. “Users can benefit from rapid, accurate, optical shaft measurement with the flexibility of a co-ordinate measuring machine. Metrology can be done rapidly and in-line as part of the production process, putting quality front and centre.”

The Opticline T3D is suited to applications in aerospace, including drive shafts, engine components and bearing parts. It also has automotive applications for engine components, gear parts and chassis. Medical manufacturers can use it for applications including joint implants, dental parts and surgical tools.

The machine is designed to last the test of time and has proven reliable performance even up to 20 years after purchase — Sempre’s service team offers technical support and will perform maintenance and calibration of the system to ensure longevity. The Opticline T3D carries its own reference standards and temperature monitoring system to further improve measurement reliability.